Ultrasonic Nougat Cutting Machine: Revolutionizing Precision in Confectionery

In the dynamic realm of confectionery, the significance of precision in cutting cannot be overstated. It is a cornerstone in ensuring the quality and consistency of products, an aspect where traditional methods often fall short in meeting the demands of today's highly competitive market. This article delves into the groundbreaking technology of ultrasonic nougat cutting machines, exploring their working mechanisms, benefits, applications, and the profound impact they have on the food industry.

Evolution of Cutting Techniques

Traditionally, confectioners heavily relied on manual cutting or mechanical blades for nougat slicing. However, these methods inherently bore limitations. As the confectionery landscape evolved, the demand for intricate designs and precise measurements paved the way for the next chapter in cutting techniques—introducing the revolutionary ultrasonic technology.

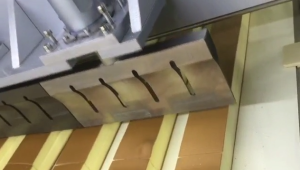

How Ultrasonic Nougat Cutting Works

Ultrasonic cutting marks a paradigm shift in the precision cutting landscape. This cutting-edge process harnesses high-frequency vibrations to achieve immaculate and precise cuts. Utilizing ultrasonic waves that generate controlled heat, the nougat is effortlessly cut with unparalleled precision. In comparison to conventional methods, ultrasonic cutting emerges as a game-changer, ensuring each nougat piece is uniform in size and shape.

Advantages of Ultrasonic Nougat Cutting Machines

1. Unmatched Precision

The primary allure of ultrasonic nougat cutting machines lies in their ability to provide unparalleled precision. The synergy of high-frequency vibrations and controlled heat during the cutting process results in flawlessly cut nougat, meeting and exceeding the stringent standards of the confectionery industry.

2. Enhanced Efficiency

Ultrasonic cutting not only ensures precision but also significantly enhances efficiency in the production process. The reduction in wastage and increased cutting speed contribute to a more streamlined and cost-effective manufacturing process, aligning with the demands of the modern confectionery landscape.

3. Versatility in Applications

From traditional nougat to an array of confectionery products, ultrasonic cutting machines showcase remarkable versatility. Their adaptability to different shapes and sizes makes them indispensable in the production of a wide range of confectionery items, providing manufacturers with unprecedented flexibility.

Applications of Ultrasonic Nougat Cutting Technology

The impact of ultrasonic nougat cutting technology reverberates across various sectors within the food industry.

1. Nougat Production

In the nougat production process, the utilization of ultrasonic cutting ensures that each piece maintains its intended shape and size. This is vital for achieving a consistent and aesthetically pleasing final product, elevating the overall quality of nougat offerings.

2. Artisan Confectionery

Artisan confectioners find immense value in the precision of ultrasonic cutting technology when crafting intricate and delicate confectionery items. The technology facilitates the creation of unique and complex designs that were once challenging to achieve with traditional cutting methods.

Ultrasonic nougat cutting machines mark a paradigm shift in the confectionery industry. The precision, efficiency, and versatility they offer address the limitations of traditional cutting methods, positioning them as a cornerstone in modern confectionery production. As consumer expectations continue to ascend, embracing innovative technologies like ultrasonic cutting becomes imperative for businesses aiming to thrive in the fiercely competitive landscape.

How Ultrasonic Nougat Cutting Works

Ultrasonic cutting is a cutting-edge process that employs high-frequency vibrations to achieve clean and precise cuts. This advanced technology utilizes ultrasonic waves to generate controlled heat, allowing the nougat to be effortlessly cut. In comparison to conventional methods, ultrasonic cutting stands out for its ability to deliver unparalleled precision, ensuring each piece is consistent in size and shape.

The Mechanism in Detail

The process begins with the emission of high-frequency vibrations from the ultrasonic cutting machine. These vibrations create a rapid back-and-forth motion in the cutting tool, effectively slicing through the nougat. Simultaneously, the ultrasonic waves generate controlled heat, which aids in the seamless cutting of the nougat without compromising its structural integrity.

Benefits of Ultrasonic Nougat Cutting Machines

The adoption of ultrasonic nougat cutting machines introduces a myriad of benefits that revolutionize the confectionery production landscape.

1. Enhanced Precision and Consistency

The primary advantage of ultrasonic cutting lies in its unparalleled precision. The high-frequency vibrations and controlled heat ensure that each cut is clean and consistent. This level of precision is crucial in the confectionery industry, where uniformity in size and shape directly impacts product quality.

2. Improved Product Quality

The enhanced precision achieved through ultrasonic cutting directly translates to improved product quality. Confectioners can produce nougat with a flawless finish, meeting the high standards demanded by consumers and the industry alike.

3. Reduced Wastage and Production Time

Ultrasonic cutting not only excels in precision but also significantly reduces wastage and production time. The seamless cutting process minimizes material loss, contributing to cost-effectiveness and sustainability in confectionery manufacturing.

4. Cost-Effectiveness

The reduction in wastage and enhanced efficiency lead to a more cost-effective production process. Confectionery manufacturers employing ultrasonic cutting technology can optimize resource utilization, ultimately benefiting their bottom line.

5. Hygienic Advantages

In the food industry, maintaining high levels of hygiene is paramount. Ultrasonic cutting machines, with their precise and clean-cutting capabilities, contribute to a more hygienic production process. This aspect makes them a preferred choice, aligning with the stringent hygiene standards of the food industry.

Ultrasonic nougat cutting machines, by virtue of their high-frequency vibrations and controlled heat, have redefined the precision in confectionery cutting. The benefits they bring, from enhanced precision and improved product quality to cost-effectiveness and hygienic advantages, position them as a game-changer in the competitive landscape of the food industry.

Choosing the Right Ultrasonic Nougat Cutting Machine

When venturing into the realm of ultrasonic nougat cutting machines, the choice you make can significantly impact the efficiency and quality of your confectionery production. Several crucial factors come into play when selecting the right machine for your business.

Factors to Consider

1. Cutting Speed

The cutting speed of an ultrasonic nougat cutting machine is a pivotal factor to evaluate. The efficiency of your production line depends on how swiftly and accurately the machine can cut through nougat. Consider your production requirements and choose a machine that aligns with your speed expectations.

2. Power Efficiency

Power efficiency is another critical consideration. Opt for a machine that not only provides high cutting speed but does so with energy efficiency. This ensures that your production processes remain cost-effective and environmentally friendly.

3. Adaptability to Nougat Types

Different confectionery products require different cutting approaches. A versatile ultrasonic cutting machine should adapt to various nougat types, from soft and chewy to dense and nut-filled. This adaptability enhances the machine's utility and makes it suitable for a broader range of confectionery applications.

4. Comparative Analysis

Before finalizing your decision, conduct a comparative analysis with other cutting technologies. While ultrasonic cutting offers unparalleled precision, it's essential to ensure it is the optimal choice for your specific production needs. Compare factors such as precision, efficiency, and maintenance requirements with alternative cutting technologies to make an informed decision.

Applications in the Food Industry

Ultrasonic nougat cutting machines have proven to be indispensable in the confectionery sector, offering versatile applications that meet and exceed industry standards.

1. Handling Various Nougat Types

One of the standout features of these machines is their ability to handle a spectrum of nougat types. Whether your product is soft and chewy or dense and nut-filled, an ultrasonic cutting machine provides the precision needed for consistent and high-quality cuts.

2. Meeting Industry Standards

Confectionery production is subject to stringent industry standards and regulations. Ultrasonic nougat cutting machines ensure compliance with these standards, contributing to the production of safe and high-quality confectionery products that meet customer expectations.

3. Indispensability in Production Lines

The versatility and precision of ultrasonic nougat cutting machines make them indispensable in modern confectionery production lines. Their ability to handle various nougat types efficiently positions them as a valuable asset, enhancing the overall efficiency and output of the production process.

Choosing the right ultrasonic nougat cutting machine involves a thoughtful consideration of factors such as cutting speed, power efficiency, and adaptability. A comparative analysis with other cutting technologies ensures that your choice aligns with your specific production requirements. The applications of these machines in the food industry, marked by versatility and compliance with standards, further solidify their importance in the ever-evolving landscape of confectionery production.

Case Studies: Transformative Impact of Ultrasonic Cutting Technology

The integration of ultrasonic cutting technology has ushered in a positive transformation for numerous businesses across various industries. Through insightful case studies, the tangible benefits of adopting these cutting-edge machines become apparent, showcasing increased efficiency, cost-effectiveness, and an undeniable improvement in product quality.

Positive Business Transformations

1. Increased Efficiency

One case study involves a confectionery manufacturer that witnessed a significant boost in production efficiency after incorporating ultrasonic cutting technology. The precision and speed of these machines allowed for a streamlined production process, reducing the overall production time and meeting consumer demand more effectively.

2. Cost-Effectiveness

A bakery adopted ultrasonic nougat cutting machines, leading to a notable reduction in operational costs. The enhanced precision and reduced wastage contributed to a more cost-effective production process. The initial investment in ultrasonic technology translated into long-term financial benefits, making it a prudent business decision.

3. Improved Product Quality

In the realm of artisan confectionery, a case study highlighted how ultrasonic cutting machines elevated product quality. The ability to precisely cut intricate designs and handle various nougat types ensured a consistent and aesthetically pleasing final product, garnering positive feedback from discerning customers.

Maintenance and Care Tips

To ensure the longevity and optimal performance of an ultrasonic nougat cutting machine, meticulous maintenance is paramount. Here are essential tips for maintaining and caring for these cutting-edge machines:

1. Regular Cleaning

Frequent cleaning is crucial to prevent the buildup of nougat residues and maintain the hygiene of the cutting components. Follow the manufacturer's guidelines for cleaning procedures to ensure the machine operates at its best.

2. Lubrication

Proper lubrication of moving parts is essential to prevent friction and wear. Regularly lubricate components as recommended by the manufacturer to ensure smooth operation and extend the lifespan of the machine.

3. Inspections

Scheduled inspections of the machine's components help identify potential issues before they escalate. Inspect blades, sensors, and other critical parts regularly to address any signs of wear or damage promptly.

4. Understanding Common Problems

Equip your team with knowledge about common issues that may arise with ultrasonic cutting machines. Understanding these problems enables quick identification and implementation of troubleshooting techniques, minimizing downtime.

5. Troubleshooting Techniques

Provide training on troubleshooting techniques to your maintenance team. This empowers them to address common problems swiftly, ensuring that the machine operates efficiently and minimizing disruptions to the production process.

The incorporation of ultrasonic cutting technology has proven transformative for businesses, as evidenced by compelling case studies showcasing increased efficiency, cost-effectiveness, and improved product quality. However, to maximize the benefits, meticulous maintenance and care are imperative. Regular cleaning, proper lubrication, inspections, and a proactive approach to addressing common problems ensure the longevity and optimal performance of ultrasonic nougat cutting machines.

Future Trends in Ultrasonic Nougat Cutting

The landscape of ultrasonic cutting technology is dynamic, with a constant flow of innovations and advancements that promise to elevate precision and efficiency to new heights. Exploring the potential improvements and developments in this cutting-edge technology provides businesses with a strategic advantage, offering a glimpse into the future of ultrasonic nougat cutting.

Anticipated Innovations and Advancements

1. Enhanced Precision through AI Integration

As artificial intelligence (AI) continues to advance, integrating AI into ultrasonic nougat cutting machines is on the horizon. This integration aims to enhance precision by allowing machines to adapt in real-time to variations in nougat density, texture, and other factors, ensuring consistently perfect cuts.

2. Increased Efficiency with Automation

Automation is expected to play a pivotal role in the future of ultrasonic cutting technology. The development of fully automated systems will further streamline the production process, reducing manual intervention and optimizing efficiency. This evolution can significantly impact the speed and cost-effectiveness of confectionery production.

3. Sustainability and Eco-Friendly Practices

Future trends indicate a growing emphasis on sustainability and eco-friendly practices in manufacturing. Ultrasonic cutting machines are likely to incorporate features and materials that align with environmentally conscious efforts, contributing to a more sustainable and responsible confectionery industry.

4. Integration with Smart Manufacturing

The concept of smart manufacturing is gaining traction, and ultrasonic nougat cutting is no exception. Future machines may seamlessly integrate with smart manufacturing systems, allowing for real-time monitoring, predictive maintenance, and data-driven insights. This integration can enhance overall operational efficiency and decision-making.

Real-world User Experiences

Businesses that have embraced ultrasonic nougat cutting technology share their experiences, highlighting the positive impact on product quality and customer satisfaction. Testimonials serve as valuable insights for those considering the adoption of this innovative technology.

1. Precision Beyond Expectations

Companies have reported precision beyond their expectations after integrating ultrasonic cutting machines. The ability to consistently produce perfectly cut nougat has not only improved the visual appeal of products but has also increased customer trust and loyalty.

2. Streamlined Production Processes

Real-world experiences emphasize the streamlined production processes facilitated by ultrasonic cutting. The reduction in production time and minimal wastage have translated into cost savings, making these machines an attractive investment for businesses aiming for efficiency and profitability.

3. Positive Impact on Customer Satisfaction

Businesses note a positive impact on customer satisfaction since implementing ultrasonic nougat cutting technology. The consistent quality, coupled with visually appealing products, has resonated well with consumers, contributing to repeat business and positive word-of-mouth marketing.

The future of ultrasonic nougat cutting holds exciting possibilities, with anticipated innovations in precision, efficiency, sustainability, and integration with smart manufacturing. Real-world user experiences further underscore the positive impact of this technology on product quality and customer satisfaction. As businesses look ahead, embracing these trends can position them at the forefront of the evolving confectionery industry.

Challenges and Solutions in Implementing Ultrasonic Nougat Cutting Technology

While ultrasonic cutting technology offers significant advantages, businesses may face challenges during its implementation. This section addresses common obstacles and provides practical tips for overcoming them, ensuring a seamless integration of this innovative technology.

Common Challenges in Implementing Ultrasonic Nougat Cutting

1. Initial Investment Costs

The upfront investment in ultrasonic cutting technology can be perceived as a significant challenge for businesses, especially smaller ones. However, the long-term benefits often outweigh the initial costs, leading to enhanced efficiency and cost-effectiveness.

2. Training and Skill Development

Transitioning to ultrasonic cutting requires training and skill development for the workforce. Employees may need to acquire new skills to operate and maintain these machines effectively. Implementing comprehensive training programs can address this challenge and ensure a skilled and confident workforce.

3. Technical Integration

Integrating ultrasonic cutting technology into existing production lines may pose technical challenges. Ensuring compatibility and seamless integration with other machinery requires meticulous planning and collaboration with experts in the field.

4. Maintenance Requirements

While ultrasonic cutting machines are efficient, they require regular maintenance to sustain optimal performance. Businesses may face challenges in establishing a robust maintenance routine. Developing a proactive maintenance schedule and providing the necessary resources can mitigate this challenge.

Practical Solutions

1. Return on Investment (ROI) Analysis

To address concerns about initial investment costs, conduct a thorough ROI analysis. Evaluate the long-term benefits, including increased efficiency, reduced wastage, and improved product quality. This analysis provides a clearer understanding of the technology's economic advantages.

2. Comprehensive Training Programs

Invest in comprehensive training programs for employees. Equip them with the necessary skills to operate and maintain ultrasonic cutting machines effectively. This not only addresses the skill development challenge but also enhances overall workforce confidence and competence.

3. Collaboration with Technology Experts

Collaborate with experts in ultrasonic cutting technology during the integration phase. Their insights can help overcome technical challenges and ensure a smooth transition. Consulting with professionals who understand the intricacies of these machines is crucial for successful implementation.

4. Proactive Maintenance Planning

Establish a proactive maintenance plan that includes regular cleaning, lubrication, and inspections. Allocating resources for a dedicated maintenance team ensures that the machines operate at their best. Additionally, having a contingency plan for unexpected downtime can further minimize disruptions.

Environmental Impact: A Comparative Analysis

An essential consideration in today's conscious business environment is the environmental impact of technology. Comparing the sustainability aspects of ultrasonic cutting with traditional methods sheds light on the eco-friendly benefits of this innovative approach.

1. Reduced Wastage

Ultrasonic cutting technology minimizes wastage significantly compared to traditional methods. The precision of cuts ensures that each piece of nougat is utilized efficiently, contributing to sustainability through reduced material waste.

2. Energy Efficiency

The energy efficiency of ultrasonic cutting machines, especially in comparison to mechanical blades, is noteworthy. This efficiency aligns with eco-friendly practices, making ultrasonic technology a more sustainable choice in the long run.

3. Sustainable Materials

Ultrasonic cutting machines often use sustainable materials in their construction. Choosing materials with a minimal environmental impact adds to the overall eco-friendly profile of these machines.

While implementing ultrasonic nougat cutting technology may present challenges, practical solutions exist to ensure a successful integration. Addressing concerns about initial costs, investing in employee training, collaborating with experts, and establishing proactive maintenance routines are crucial steps. Moreover, the comparative analysis of environmental impact highlights the eco-friendly benefits of ultrasonic cutting technology, making it a sustainable choice for conscious businesses.

Cost Analysis:

Investing in ultrasonic nougat cutting technology involves an initial upfront cost. However, a comprehensive cost analysis reveals the long-term benefits and return on investment, making it a strategic investment for businesses aiming for efficiency and quality.

Comprehensive Cost Analysis

1. Upfront Investment

The initial cost of acquiring ultrasonic nougat cutting machines can be perceived as a substantial investment. Businesses considering this technology should conduct a thorough cost analysis that includes the purchase price of the machines, installation costs, and any necessary modifications to existing production lines.

2. Operational Costs

Operational costs encompass ongoing expenses such as energy consumption, maintenance, and potential repairs. While ultrasonic cutting machines are known for their efficiency, it is essential to factor in these operational costs for a holistic understanding of the investment.

3. Long-term Benefits

The true value of ultrasonic nougat cutting technology becomes apparent in the long term. The precision, reduced wastage, and improved production efficiency contribute to long-term benefits that positively impact the bottom line. Businesses should consider these benefits when evaluating the overall cost-effectiveness of the technology.

Return on Investment (ROI)

1. Increased Efficiency

One of the primary contributors to the return on investment is the increased efficiency brought about by ultrasonic cutting technology. The speed and precision of these machines streamline the production process, reducing overall production time and increasing output.

2. Reduced Wastage

The precision of ultrasonic cutting ensures minimal wastage of raw materials. This reduction in wastage translates directly into cost savings, contributing to the overall return on investment. Businesses can optimize resource utilization and minimize environmental impact through reduced material waste.

3. Improved Product Quality

The enhanced precision offered by ultrasonic cutting machines results in consistently high product quality. This improvement in quality can positively impact customer satisfaction, leading to increased sales and brand loyalty—a critical factor in determining the return on investment.

Training and Skill Development

Proper training for machine operators is vital in maximizing the benefits of ultrasonic nougat cutting. Resources for skill development and training programs are available, ensuring operators are well-equipped to handle these advanced machines.

1. Operator Competence

Investing in training programs ensures that machine operators acquire the necessary skills to operate ultrasonic cutting machines efficiently. Operator competence is crucial for optimizing the performance of the machines and achieving the desired precision in nougat cutting.

2. Efficient Machine Operation

Well-trained operators contribute to efficient machine operation. They can troubleshoot common issues, perform routine maintenance, and ensure that the machines run at peak performance. This efficiency is integral to realizing the long-term benefits of the technology.

3. Access to Resources

Businesses can leverage available resources for skill development, including training materials, workshops, and expert guidance. Access to these resources ensures that operators stay updated on best practices and advancements in ultrasonic nougat cutting technology.

While the initial investment in ultrasonic nougat cutting technology may seem substantial, a comprehensive cost analysis reveals the strategic advantages and long-term benefits. Increased efficiency, reduced wastage, and improved product quality contribute to a positive return on investment. Proper training and skill development for machine operators further maximize the benefits, ensuring businesses make the most of this advanced and efficient technology.

Conclusion

In conclusion, the ultrasonic nougat cutting machine represents a revolutionary leap in confectionery production. The unparalleled precision, efficiency, and hygienic advantages make it a game-changer for businesses seeking to elevate their product quality and streamline production processes.

FAQs

Q1: Are ultrasonic nougat cutting machines suitable for all types of nougat?

Yes, these machines are designed to handle a wide range of nougat varieties, ensuring versatility in confectionery production.

Q2: How do ultrasonic cutting machines contribute to cost savings?

The precision in cutting reduces wastage, leading to cost savings in raw materials. Additionally, the efficiency of these machines minimizes production time.

Q3: What maintenance is required for ultrasonic nougat cutting machines?

Regular cleaning, lubrication, and inspections are essential for maintaining the longevity and performance of these machines.

Q4: Can ultrasonic cutting technology be retrofitted into existing production lines?

Yes, many manufacturers offer retrofitting options, allowing businesses to integrate ultrasonic cutting into their current production processes.

Q5: Are there any environmental benefits to using ultrasonic cutting technology?

Yes, ultrasonic cutting machines are known for their energy efficiency and reduced waste, contributing to a more sustainable and environmentally friendly production process.