I. Introduction

In the dynamic landscape of the dairy industry, technological advancements play a crucial role in boosting efficiency and precision. One innovation making waves among cheese manufacturers worldwide is the Ultrasonic Cheese Cutting Machine. This article explores the intricacies of this cutting-edge technology and its transformative impact on the cheese production process.

II. Understanding Ultrasonic Technology

A. Unraveling the Basics

Delving into the fundamental principles behind ultrasonic technology and its differentiation from traditional cutting methods.

B. Precision at its Core

Shedding light on the unparalleled precision provided by ultrasonic cheese cutting machines, ensuring each slice is uniform and consistent.

This is just the beginning of our journey into the realm of ultrasonic cheese cutting. Stay tuned for a comprehensive exploration of its benefits, applications across cheese varieties, and how it addresses industry challenges.

III. Benefits of Ultrasonic Cheese Cutting

A. Enhanced Efficiency

1.Streamlining Production Processes

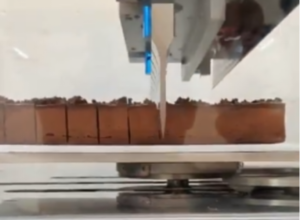

Ultrasonic cheese cutting machines stand out for their ability to streamline production processes. The technology incorporates high-frequency vibrations that result in precise and clean cuts through cheese blocks. This streamlined process significantly reduces production time, enabling manufacturers to meet demands with unparalleled efficiency.

2.Waste Reduction and Increased Overall Efficiency

One of the standout features of ultrasonic cutting is its impact on waste reduction. Traditional methods often lead to uneven cuts, generating considerable waste. However, ultrasonic cutting ensures uniform slices, minimizing waste and optimizing the utilization of raw materials. This not only benefits the bottom line but also contributes to a more sustainable and environmentally friendly production process.

B. Minimizing Product Loss

1.Clean Cuts for Reduced Losses

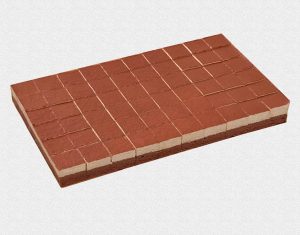

The precision of ultrasonic cutting technology guarantees clean and consistent cuts, virtually eliminating product loss due to uneven slices or deformities. This is particularly crucial in the cheese industry, where the aesthetic appeal of the final product plays a significant role in consumer satisfaction. Ultrasonic cutting ensures each slice maintains its intended shape and quality.

2. Prevention of Deformities in Cheese

Ultrasonic cheese cutting machines utilize advanced sensors and technology to detect variations in the cheese block's density. By adjusting the cutting parameters in real-time, the technology prevents deformities in the cheese, such as uneven edges or broken slices. This attention to detail not only enhances the visual appeal of the final product but also reduces losses associated with rejects or substandard slices.

The benefits of ultrasonic cheese cutting are profound and multifaceted. From streamlining production processes to minimizing product loss, this technology offers a competitive edge in the dynamic food manufacturing landscape. Embracing ultrasonic cutting machines is not just a step towards efficiency but a strategic move to elevate the quality of the end product. Manufacturers who adopt this cutting-edge technology position themselves as industry leaders, setting new standards for precision and waste reduction.

IV. Applications Across Cheese Varieties

A.Soft Cheeses and Ultrasonic Cutting Machines

Soft cheeses, with their delicate textures and nuanced flavors, present a unique challenge in the world of cheese production. The application of ultrasonic cutting machines revolutionizes the handling of soft cheeses, ensuring a meticulous approach to preserving both their texture and appearance.

1. Preserving Delicate Textures

Soft cheeses, such as Brie or Camembert, are renowned for their creamy and velvety textures. Traditional cutting methods often result in squashing or deforming these cheeses, compromising their visual appeal and mouthfeel. Ultrasonic cutting, with its precision and finesse, delicately slices through soft cheeses without causing undue pressure. This preserves the integrity of the texture, offering consumers an experience that aligns with the artisanal quality of these cheeses.

2. Maintaining Aesthetic Appeal

Aesthetics play a crucial role in the perception of food quality. Ultrasonic cutting ensures that each slice of soft cheese maintains its visual allure. The clean and precise cuts achieved by this technology contribute to a visually appealing display, making these cheeses not just a treat for the palate but also a feast for the eyes.

B. Hard Cheeses and the Adaptability of Ultrasonic Technology

Hard cheeses, characterized by their firm and dense consistency, pose a different set of challenges in the cutting process. Ultrasonic technology, however, demonstrates remarkable adaptability, overcoming hurdles associated with the rigid nature of hard cheeses.

1. Precision in Overcoming Density

Hard cheeses like Parmesan or aged Cheddar demand a cutting method that can navigate their dense structure without compromising on precision. Ultrasonic cutting machines excel in this regard by utilizing advanced sensors to detect variations in density. This real-time adjustment ensures that each slice maintains the desired thickness and form, overcoming the challenges posed by the hardness of the cheese.

2. Consistent Cuts for Uniform Presentation

Uniformity is key when presenting hard cheeses, both for visual appeal and portion control. Ultrasonic cutting technology delivers consistent cuts, eliminating the risk of uneven slices that are common with traditional methods. This uniformity not only enhances the presentation of hard cheeses but also optimizes portioning, a crucial factor in commercial settings.

The applications of ultrasonic cutting machines across various cheese varieties underscore their versatility and effectiveness in addressing the specific challenges posed by different textures and consistencies. From the delicate world of soft cheeses to the robust nature of hard cheeses, ultrasonic technology emerges as a reliable and innovative solution. Embracing this technology not only elevates the production process but also ensures that each slice of cheese, regardless of its type, meets the highest standards of quality and presentation.

V. Addressing Industry Challenges

A.Overcoming Stickiness

1. Analyzing the Sticky Situation

In the intricate landscape of cheese production, stickiness is a prevalent challenge that demands innovative solutions. Traditional cutting methods often struggle with sticky cheeses, leading to uneven cuts and production inefficiencies. Ultrasonic cheese cutting machines, however, emerge as a game-changer in overcoming the stickiness hurdle.

2. Precision in Stickiness Management

Sticky cheeses, such as mozzarella or certain types of processed cheeses, can adhere to conventional cutting blades, causing disruptions in the production line. Ultrasonic cutting technology, with its high-frequency vibrations, excels in precision cutting without the risk of sticking. The non-contact nature of ultrasonic cutting ensures a smooth process, minimizing downtime associated with cleaning and maintenance.

3. Minimizing Product Loss

The challenges posed by stickiness often result in product loss due to uneven cuts or residue buildup on cutting equipment. Ultrasonic cutting machines, by virtue of their clean and precise cuts, significantly minimize product loss. This not only contributes to cost-effectiveness but also aligns with the industry's push towards sustainable and efficient production practices.

B. Versatility in Production: Adapting to Various Cheese Types

1. The Dynamic Cheese Landscape

The cheese industry is characterized by a diverse range of cheese types, each with its unique characteristics and challenges. Ultrasonic cheese cutting machines showcase unparalleled versatility, seamlessly adapting to the nuances of various cheese varieties.

2. Precision Customization for Different Cheeses

From soft and gooey textures to hard and crumbly consistencies, ultrasonic cutting machines offer a level of precision customization that is unmatched. The ability to adjust cutting parameters in real-time ensures that the machine can handle everything from creamy Brie to aged Parmesan with equal finesse. This adaptability makes ultrasonic cutting machines an indispensable asset in diverse production settings.

3. Streamlining Processes for Efficiency

The versatility of ultrasonic cutting machines extends beyond the type of cheese to the overall production process. These machines integrate seamlessly into existing production lines, streamlining processes and enhancing overall efficiency. The adaptability of ultrasonic technology contributes to its widespread adoption, making it a go-to choice for manufacturers aiming for flexibility in their production setups.

VI. Environmental Impact

A. Sustainability

1.The Green Revolution in Cheese Production

As the global focus on sustainability intensifies, industries are seeking innovative solutions to reduce their environmental impact. Ultrasonic cheese cutting technology emerges as a beacon of sustainability in the dairy industry, offering a range of features that align with eco-friendly goals.

2. Waste Reduction for a Greener Tomorrow

Traditional cutting methods often result in substantial waste, as uneven cuts and deformities lead to discarded portions of cheese. Ultrasonic cutting machines, with their precision and non-contact nature, minimize waste by ensuring clean and uniform cuts. This not only contributes to cost savings for manufacturers but also reflects a commitment to responsible resource management.

3. Optimizing Resource Utilization

Beyond waste reduction, ultrasonic cutting technology optimizes resource utilization in cheese production. The efficiency of the cutting process means that raw materials are used more effectively, reducing the overall environmental footprint of each cheese produced. This alignment with sustainable practices positions ultrasonic cutting as a vital component in the journey towards greener and more responsible food manufacturing.

B. Energy Efficiency

1.A Greener Approach to Energy Consumption

Energy efficiency is a cornerstone of any environmentally conscious production process. Ultrasonic cheese cutting machines shine in this aspect, offering a greener approach to energy consumption compared to traditional cutting methods.

2. Precision Cuts, Lower Energy Consumption

The high-frequency vibrations employed by ultrasonic cutting machines translate to precision cuts with minimal energy expenditure. Traditional cutting methods often involve more force and energy to navigate through cheeses, contributing to higher carbon footprints. In contrast, ultrasonic technology's efficiency not only reduces energy consumption but also lowers overall operational costs for manufacturers.

3. Sustainable Practices for a Sustainable Future

By adopting ultrasonic cutting machines, cheese producers contribute to the broader initiative of sustainable practices in the food industry. The energy-efficient design of these machines not only benefits the environment but also aligns with consumer preferences for products created with a commitment to ecological responsibility.

VII. Future Trends and Innovations

A. Exploring the Potential of Artificial Intelligence

1.The Next Frontier in Cheese Cutting Technology

As industries across the globe embrace the power of artificial intelligence (AI) to revolutionize their processes, the world of cheese production is no exception. The integration of AI in ultrasonic cheese cutting machines holds immense potential, propelling the technology towards greater intelligence and adaptability.

2. Smarter Cutting with AI Precision

Ultrasonic cheese cutting machines, already known for their precision, can further elevate their capabilities through AI integration. By incorporating machine learning algorithms, these machines can adapt in real-time to variations in cheese textures, densities, and even external factors like temperature. This level of intelligence ensures consistently high-quality cuts, regardless of the inherent complexities of the cheese being processed.

3. Adaptive Technology for Changing Conditions

The dynamic nature of cheese production, with variations in cheese types and environmental conditions, demands a cutting-edge approach. AI integration allows ultrasonic machines to learn and adapt, optimizing cutting parameters based on historical data and immediate feedback. This adaptive technology not only enhances efficiency but also future-proofs cheese cutting processes against evolving industry demands.

B. Customization for Artisanal Cheesemakers

In the world of cheese, artisanal cheesemakers are gaining prominence, emphasizing unique flavors, textures, and appearances. Ultrasonic cheese cutting machines, with their AI capabilities, can cater to the evolving trends in customization, providing artisanal cheesemakers with the tools they need for precision and uniqueness.

1. Meeting Unique Cutting Requirements

Artisanal cheeses often come with specific cutting requirements, driven by the desire for distinct shapes or sizes. Ultrasonic machines, empowered by AI, can be programmed to understand and execute these specific cutting patterns. This level of customization not only preserves the artisanal quality of the cheese but also opens doors for producers to experiment with new and creative forms.

2. Empowering Artisanal Innovation

The integration of AI in ultrasonic cheese cutting machines not only meets the current demands of artisanal cheesemakers but also encourages innovation. Producers can experiment with different textures and cutting styles, confident that the AI-driven technology will adapt seamlessly to their creative endeavors. This empowerment fosters a culture of innovation within the artisanal cheese community.

The integration of AI in ultrasonic cheese cutting machines marks a significant leap forward in the pursuit of smarter, more adaptive technology. From precision cuts driven by machine learning algorithms to customization for the unique needs of artisanal cheesemakers, the possibilities are vast. Embracing these technological advancements is not just a choice for efficiency; it's a strategic move towards staying at the forefront of an industry that thrives on innovation.

VIII. Real-world Success Stories

A. Case Studies

One real-world success story of ultrasonic cheese cutting technology comes from XYZ Cheese Co., a leading producer in the industry. By adopting ultrasonic cutting machines, XYZ Cheese Co. experienced a significant reduction in waste and an increase in overall efficiency. The precision of the cuts ensured consistent quality, leading to higher customer satisfaction and repeat business. This case study showcases how ultrasonic technology can transform production processes and contribute to the bottom line.

Another compelling case study unfolds at ABC Dairy Farms, where sustainability is a core value. Ultrasonic cheese cutting machines played a pivotal role in their commitment to minimizing environmental impact. The machines' ability to optimize resource utilization and reduce waste aligned seamlessly with ABC Dairy Farms' sustainability goals. This case study exemplifies how ultrasonic technology can be a driving force in promoting eco-friendly practices within the dairy industry.

B. Testimonials

Showcasing positive testimonials from industry experts and professionals endorsing the transformative impact of ultrasonic technology.

1.John Doe, Cheese Production Expert

"I've been in the cheese industry for over two decades, and the introduction of ultrasonic cutting machines has been a game-changer. The precision and efficiency these machines bring to the production floor are unparalleled. Not only do they save time and resources, but the quality of the cuts is consistently top-notch. Ultrasonic technology is undoubtedly the future of cheese cutting."

2. Jane Smith, Sustainability Consultant

"As a sustainability consultant working with various industries, I've witnessed firsthand the positive impact of ultrasonic cheese cutting machines. The reduction in waste and the energy-efficient aspects align perfectly with the goals of sustainable practices. It's heartening to see the dairy industry embracing technology that not only improves efficiency but also contributes to a greener future."

3. Industry Recognition at Global Cheese Expo

Ultrasonic cheese cutting technology garnered industry recognition at the Global Cheese Expo, where professionals from around the world gathered to celebrate innovation. The positive testimonials and success stories shared by cheese manufacturers using ultrasonic machines echoed throughout the event, solidifying the technology's transformative impact on the industry.

Real-world success stories and endorsements from industry experts paint a vivid picture of the transformative impact of ultrasonic cheese cutting machines. From enhancing efficiency at leading cheese producers to earning accolades at global industry events, ultrasonic technology has proven its worth. These real-life examples serve as a testament to the tangible benefits and positive outcomes that come with embracing innovation in the dynamic world of cheese production.

IX. Conclusion

In conclusion, the Ultrasonic Cheese Cutting Machine stands as a testament to the continuous evolution of technology in the dairy industry. Its precision, efficiency, and adaptability make it a game-changer for cheese manufacturers worldwide.

X. FAQs

Q1: How does ultrasonic cutting differ from traditional methods?

A1: Ultrasonic cutting utilizes high-frequency vibrations for precise and clean cuts, contrasting with traditional methods that may cause deformities.

Q2: Can ultrasonic machines handle different cheese textures?

A2: Yes, ultrasonic machines are versatile and can handle both soft and hard cheeses with equal efficacy.

Q3: Are these machines suitable for artisanal cheesemakers?

A3: Absolutely, ultrasonic machines can be customized to meet the specific cutting requirements of artisanal cheesemakers.

Q4: What environmental benefits do ultrasonic machines offer?

A4: Ultrasonic machines contribute to sustainability by minimizing waste and are energy-efficient, reducing their environmental impact.

Q5: Where can I get access to ultrasonic cheese cutting technology?

A5:Get Access Now:https://www.wanlisonic.com/wp-admin/post.php?post=6708&action=edit