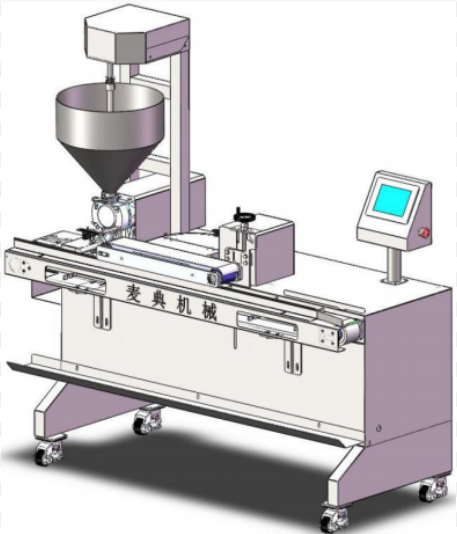

The equipment is mainly an auxiliary device for increasing the variety of bread, which is to cut in the middle of the bread, and then clip jam, cream, or salad dressing in the middle of the bread to make the product taste more delicious and not greasy. The equipment is transported, cut, and grouted in one go, and the product is transported to the cutting knife cut using a synchronous transportation method of upper conveyor belt and chain conveyor belt. The cut is smooth and flat without deformation. The cutting method can be cut from the side or from above, and is suitable for filling different sizes of toast, bread, and cake.

The Evolution of Food Preparation Technology

The Hamburg Cutting and Sandwich Machine represents a significant advancement in food preparation technology. With its state-of-the-art design and functionality, it has transformed the way hamburgers and sandwiches are made. This machine combines precision cutting with speed, allowing businesses to meet the demands of their customers efficiently. Its automated features ensure consistent results, reducing human error and improving overall quality.

Features and Benefits of the Hamburg Cutting and Sandwich Machine

The Hamburg Cutting and Sandwich Machine boasts a range of features that make it a game-changer in the food industry. Firstly, it offers adjustable cutting thickness, allowing businesses to cater to different preferences and dietary requirements. Whether customers prefer thick or thin patties or sandwiches, this machine can deliver. Additionally, it has a high cutting capacity, enabling businesses to process a large volume of orders in a short amount of time. This feature is particularly advantageous for fast food chains and busy restaurants.

Enhanced Efficiency and Productivity

By incorporating the Hamburg Cutting and Sandwich Machine into their operations, businesses can significantly enhance their efficiency and productivity. This machine streamlines the food preparation process, reducing the time and effort required to cut hamburgers and sandwiches manually. With its automated cutting mechanism, it can produce consistent results at a much faster pace. This increased efficiency allows businesses to serve more customers and fulfill orders promptly, leading to higher customer satisfaction and repeat business.

Improved Food Safety and Hygiene

Food safety and hygiene are paramount in the food industry, and the Hamburg Cutting and Sandwich Machine addresses these concerns effectively. Its design ensures that the cutting process is hygienic and minimizes the risk of cross-contamination. The machine is easy to clean and maintain, reducing the chances of bacterial growth and ensuring compliance with food safety regulations. By investing in this machine, businesses can prioritize the well-being of their customers and maintain a positive reputation.

Versatility and Customization Options

The Hamburg Cutting and Sandwich Machine offers versatility and customization options, allowing businesses to cater to a wide range of customer preferences. It can cut various types of bread and buns, accommodating different sandwich sizes and shapes. Additionally, the adjustable cutting thickness feature enables businesses to create customized hamburgers and sandwiches according to customer requests. This versatility allows businesses to differentiate themselves from competitors and attract a diverse customer base.

In conclusion

The Hamburg Cutting and Sandwich Machine has transformed the food industry by offering efficiency, precision, and customization options. Its features and benefits make it an indispensable tool for businesses in the restaurant, fast food, and catering sectors. By investing in this machine, businesses can enhance their productivity, improve food safety, and ultimately increase profitability. As technology continues to advance, we can expect further innovations that will shape the future of food preparation.