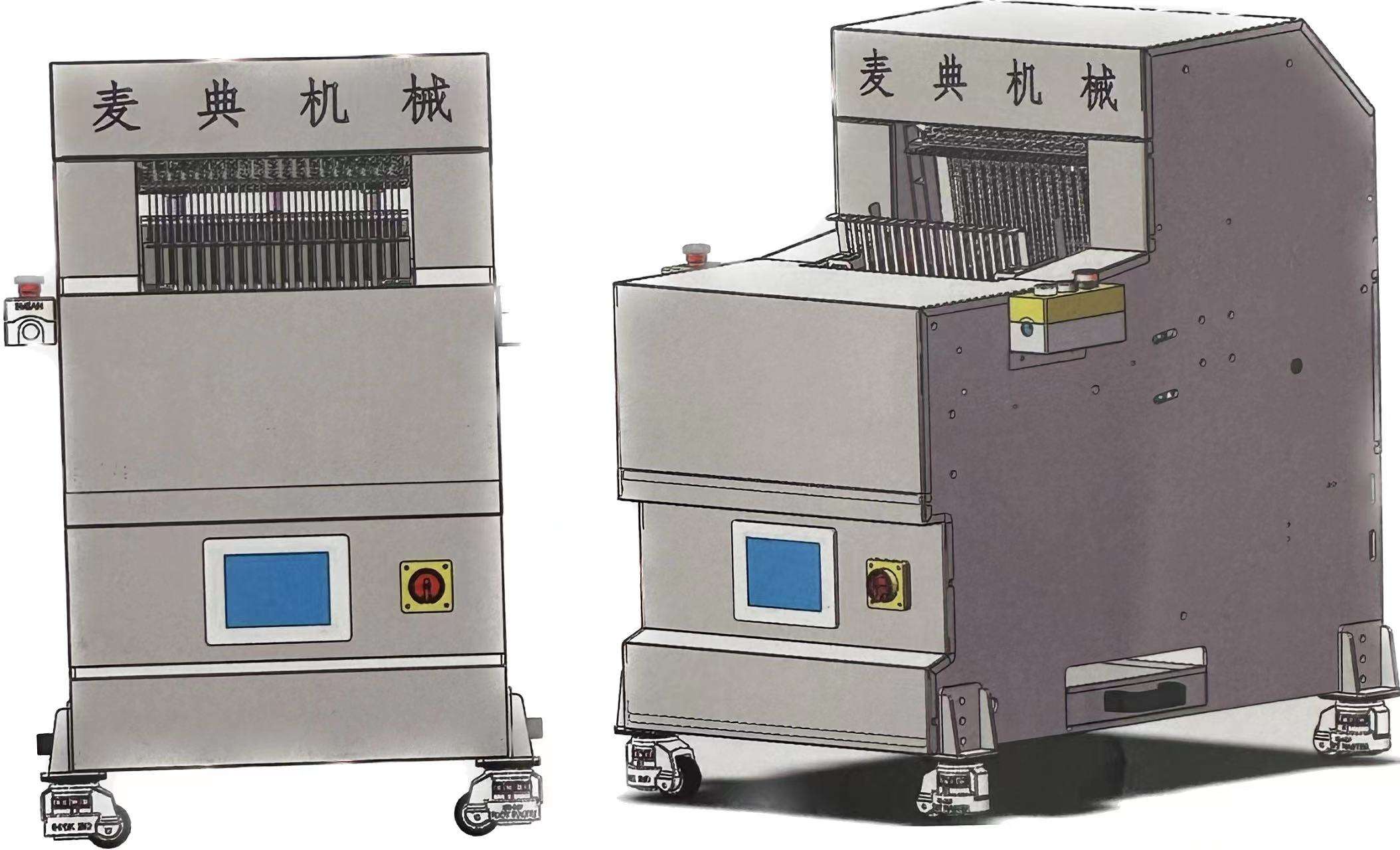

Mainly used by bread manufacturers for slicing and semi slicing bread. The thickness dimensions of slicing and semi slicing are customized according to different requirements of the manufacturer, with high efficiency, smooth and flat slicing, safety and hygiene, and other advantages.

1. The Evolution of Bread Slicing Technology

The bread industry has come a long way in terms of slicing technology. From manual slicing to automated solutions, the industry has witnessed significant advancements. The introduction of Bread Half Slicer has been a game-changer, offering unparalleled precision and efficiency. This machine has revolutionized the way bread is sliced, ensuring uniformity and consistency in every slice.

2. Features and Functionality

The Industry Bread Half Slicer boasts an array of features that make it a standout choice for bakeries and food manufacturers. Its advanced slicing mechanism ensures clean and precise cuts, minimizing wastage and maximizing productivity. The machine is equipped with adjustable settings, allowing users to customize the thickness of each slice according to their specific requirements. Additionally, the slicer's user-friendly interface and easy maintenance make it a preferred choice for businesses of all sizes.

3. Applications in the Food Industry

The Bread Half Slicer finds its applications in various sectors of the food industry. Bakeries, sandwich shops, and food manufacturing units greatly benefit from this machine. Its ability to slice bread quickly and accurately makes it an indispensable tool for businesses that rely on high-volume bread production. Moreover, the slicer's versatility allows it to handle different types of bread, including baguettes, loaves, and buns, catering to a wide range of customer preferences.

4. Advantages of Bread Half Slicer

Bread Half Slicer offers numerous advantages that contribute to its growing popularity in the food industry. Firstly, its precision slicing ensures consistent thickness, enhancing the visual appeal of the bread and improving customer satisfaction. Secondly, the machine's high-speed operation significantly reduces labor costs and increases overall productivity. Additionally, the adjustable settings allow businesses to cater to the diverse needs of their customers, offering a competitive edge in the market.

5. Impact on Efficiency and Profitability

The implementation of Bread Half Slicer has a direct impact on the efficiency and profitability of businesses in the food industry. By automating the bread slicing process, companies can save valuable time and resources, allowing them to focus on other aspects of production. The machine's ability to slice bread quickly and uniformly also reduces the need for manual labor, resulting in cost savings and increased profitability.

6. Maintenance and Safety Considerations

Proper maintenance and safety protocols are crucial when using the Industry Bread Half Slicer. Regular cleaning and lubrication ensure the machine's longevity and optimal performance. Additionally, operators should receive proper training to operate the slicer safely, minimizing the risk of accidents or injuries. Adhering to these maintenance and safety guidelines not only protects the machine but also ensures the well-being of the operators.

Conclusion

Bread Half Slicer has undoubtedly revolutionized the bread-making process in the food industry. Its advanced features, versatility, and precision slicing capabilities make it an indispensable tool for businesses seeking to enhance efficiency and productivity. By investing in this innovative machine, bakeries and food manufacturers can streamline their operations, reduce costs, and ultimately increase profitability. Embracing the Industry Bread Half Slicer is a step towards staying ahead in the competitive food industry landscape.

Jorna Su Hong(Senior Customer Consultant)

(Excellent Quality, Excellent Price & Excellent Service)

Tel: 86-13400979434

We Chat/Whats App: 008613400979434