What is the Wanlisonic Ultrasonic Pizza Cutting Machine?

Imagine slicing through a hot, cheesy pizza without dragging the toppings or deforming the crust. That’s exactly what the Wanlisonic Ultrasonic Pizza Cutting Machine does. It’s a state-of-the-art food cutting machine that uses high-frequency ultrasonic vibrations to cut pizza cleanly and efficiently — no smearing, no mess, no hassle.

Why is it Revolutionizing the Pizza Industry?

Because speed, hygiene, and consistency are everything in food production. Wanlisonic brings all of that in one sleek, powerful package.

The Science Behind Ultrasonic Cutting

How Ultrasonic Technology Works

Ultrasonic cutting involves a blade that vibrates at a frequency of around 20,000 to 40,000 times per second. These micro-vibrations create a nearly frictionless cut, which glides through food products like a hot knife through butter — but cooler, cleaner, and much more precise.

Why Ultrasonic is Better Than Traditional Cutting

Traditional blades rely on force. Ultrasonic blades rely on frequency. The result? No squishing, no dragging, and minimal sticking. You maintain the integrity of your product — every single time.

Features of the Wanlisonic Ultrasonic Pizza Cutter

High-Frequency Blade Movement:The blades vibrate ultrasonically, slicing through crust, cheese, and toppings with pinpoint accuracy.

Precise and Clean Cuts:Whether it’s thin-crust, deep-dish, or gluten-free — you get uniform slices with no ragged edges.

Temperature Control:No overheating issues. The ultrasonic blade stays cool, ensuring no melting or burning of ingredients.

Food-Safe and Hygienic Design:Built with food-grade stainless steel and easy-to-clean surfaces. Fewer crevices mean less bacteria buildup.

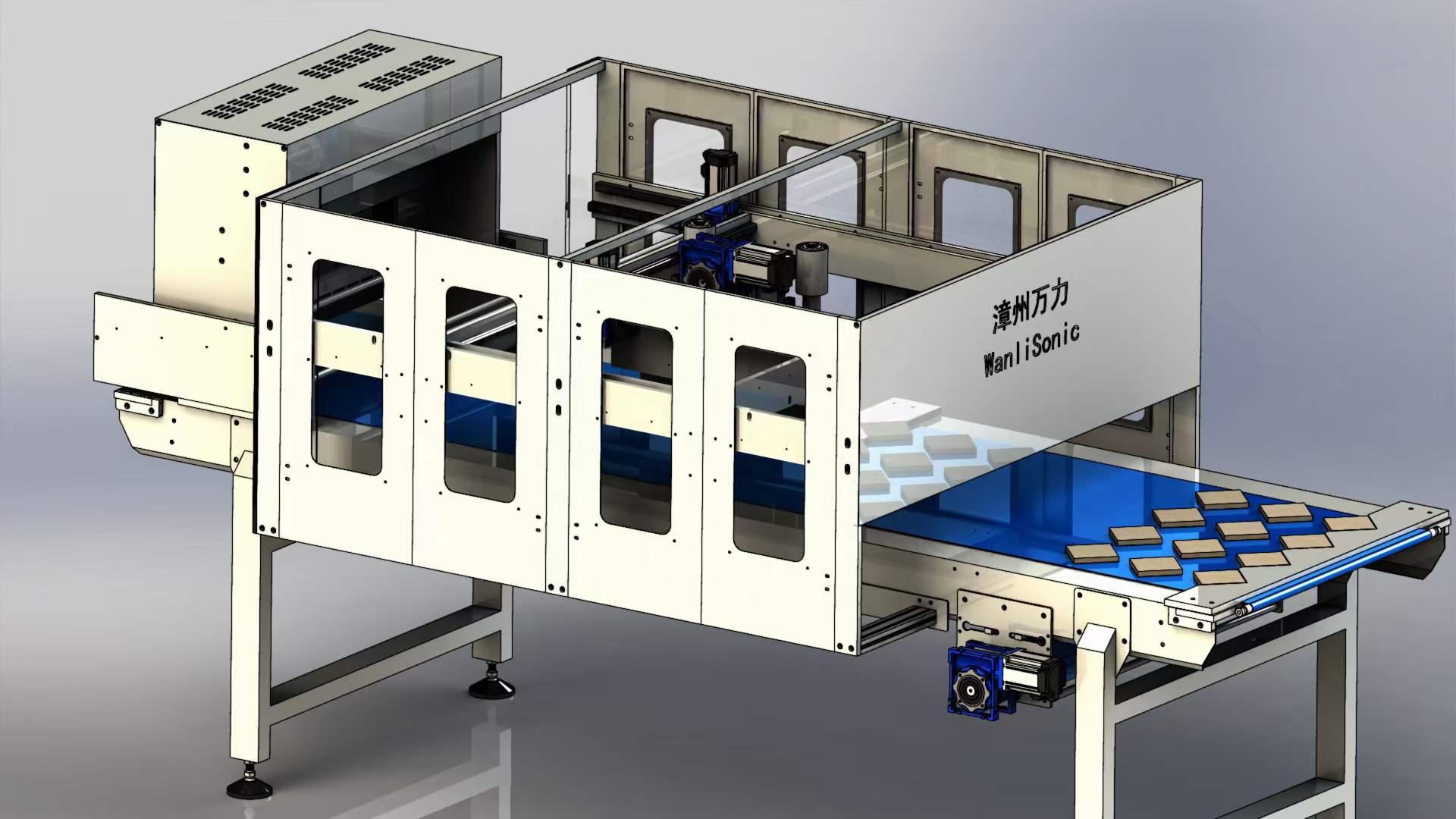

Customization Options:Choose from single-blade, multi-blade, or fully automated conveyor systems based on your needs

Benefits for Pizza Manufacturers

Increased Production Speed:More pizzas, less time. Automated systems can cut hundreds of pizzas per hour with no slowdown.

Reduced Waste:Clean cuts mean fewer broken slices and reduced product loss.

Improved Product Consistency:Perfectly sliced pizzas look better and perform better in the market.

Enhanced Hygiene Standards:Contactless cutting reduces the risk of contamination, a must-have in modern food facilities.

Comparison With Traditional Pizza Cutting Methods:

Manual Cutting vs Ultrasonic,Manual cutting is labor-intensive and inconsistent. Ultrasonic cutting? Fast, hands-free, and precise.

Rotary Blades vs Ultrasonic Blades:Rotary blades dull quickly and need frequent cleaning. Ultrasonic blades stay sharper longer and resist buildup.

Technical Specifications:Blade Dimensions Available in multiple sizes to suit different pizza diameters, from 6″ to 18″.Power and Frequency,Typically runs on 220V with customizable frequency settings depending on the crust density and product type.

Customization and Automation Options

Conveyor Integration:Sync with your production line for seamless, continuous slicing.

Programmable Cutting Patterns:pre-program your cutting patterns for consistency and speed.

Multi-Product Cutting:Cut sandwiches, pies, and even quiches with interchangeable blade modules

Ease of Use and Maintenance

User-Friendly Interface:Touchscreen controls and programmable settings make operation a breeze.

Easy Cleaning and Maintenance:Quick-disassemble parts reduce downtime and comply with sanitary standards.

Long-Term Durability:Built for industrial environments, with corrosion-resistant materials and reliable components.

Safety Features

Automatic Shutoff:Built-in sensors turn the machine off when not in use or if a foreign object is detected.

Sensor-Based Blade Activation:Only activates when a pizza is properly aligned — no risk of accidents.

Emergency Stop Systems:Easily accessible emergency stop buttons keep operators safe at all times.

How to Choose the Right Model

Size of Operation:Small kitchen? Go with a standalone cutter. Large factory? Get the fully automated conveyor model.

Budget and ROI Considerations:While the initial investment is higher than traditional methods, the long-term ROI through labor savings, reduced waste, and product quality makes it worth every cent.

Customization Needs:Wanlisonic offers tailored solutions to meet specific business needs

The Future of Pizza Cutting

Innovations in Food Tech:AI-guided cutting, laser measurement, and integration with IoT — the future is already on the drawing board.

Sustainability in Cutting Technologies:Lower energy consumption and minimal waste production contribute to greener food processing.

The Wanlisonic Ultrasonic Pizza Cutting Machine is more than just a slicer — it’s a game-changer for the pizza industry. Whether you’re running a small kitchen or a massive production line, this machine boosts efficiency, ensures perfect slices, and helps you deliver the best product to your customers — every single time. It’s the ultimate upgrade your business didn’t know it needed.