The origin of Ultrasonic cheesecake and bread slicer machine

Bread is probably one of the most convenient staple foods. Unlike noodles and rice, which need to be cooked and eaten immediately, bread can be stored for several days after it is baked. In the 18th century, the sandwich was born, and it became popular in the United States in the 19th century. As the protagonist of the sandwich, the status of sliced bread is even more distinguished.

However, bakeries at that time did not sell sliced bread, and housewives could only buy whole loaves and slice them themselves. In order to cater to the popular taste, commercially produced bread is often made moist and soft, requiring extremely sharp serrated knives and great skill to slice it. Even so, the slices of bread sliced by hand will be somewhat uneven in thickness, and the sandwiches made are not very square. Cutting slices of bread has become one of the most troublesome problems for housewives. OttoRohwedder noticed this phenomenon and smelled unlimited business opportunities. He published a questionnaire in the newspaper to find out the housewives' favorite thickness of bread, and after a few months, he collected feedback from 30,000 housewives.

However, the development process was not smooth. It is not difficult to slice the bread, but the area of the sliced bread exposed to the air increases, the water evaporates faster, and the shelf life is greatly shortened. In order to overcome this problem, Rowedel borrowed the shape of the hat pin (Hatpin), pierced the bread with a long metal needle, and fixed the two ends to ensure that the bread slices fit tightly together, trying to slow down its hardening process. speed. Not to mention how much the idea of threading a needle in bread affects appetite, practice has proved that the fixing parts at both ends of the metal needle are easy to fall off, and cannot play a role in keeping fresh.

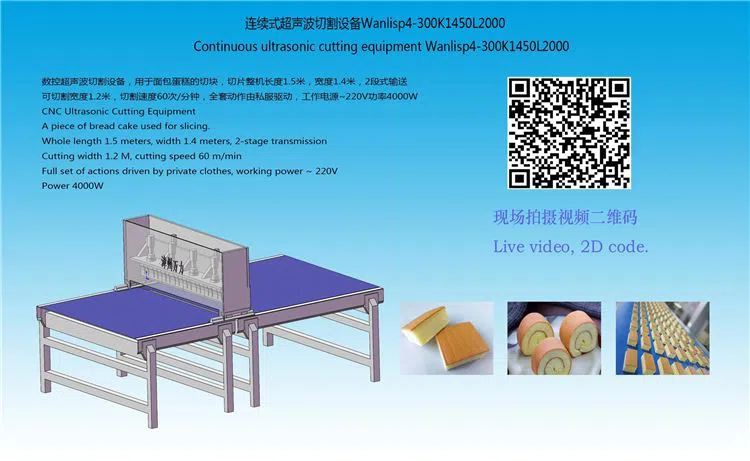

Due to the turmoil in the current situation and family factors, it took a full ten years before Rowedel built the second Ultrasonic cheesecake and bread slicer machine. This time, he designed a program for automatically wrapping bread, and switched to thick wax paper as the wrapping paper, which insulated the evaporation of water and solved the problem that sliced bread tends to harden. With the development of economy and technology, the technology of Ultrasonic cheesecake and bread slicer machine has been further improved. Ultrasonic cheesecake and bread slicer machine is a facility for cutting bread or steamed buns into slices. This machine can be used for bread, spit It can be used for slicing and dicing various products such as bread, steamed buns, ham, etc. The bread slicer adopts domestic blades and can also be equipped with imported blades. It is easy to operate, sharp and durable, fast in slicing speed, flat incision, less debris, neat in shape, and even in thickness. ,efficient.

Ultrasonic cheesecake and bread slicer machine features

1. The bread slicer has a fine design and structure, and the shell can choose multi-layer baking paint, which has a beautiful appearance.

2. Professional design, export blade, sharp and durable, can be used for shredding and dicing processing.

3. It adopts stainless steel blanking plate, bread slicer receiving plate, limit line branch and limit plate, which conform to the current hygienic standard.

4.Ultrasonic cheesecake and bread slicer machine adopts high-quality motor with high torque, low noise, high efficiency and quiet operation.

5. Simple and fast operation, high efficiency, quiet operation, uniform cutting force and flat cutting surface.

6. The blade of the bread slicer is made of high-quality stainless steel, which will not break when bent.

7. The cutting edge is sharp, the efficiency is high, the incision is smooth, the slice is uniform and beautiful, and there is no debris.

8. Slicing for a long time, still sharp and not deformed, the bread cut out by Ultrasonic cheesecake and bread slicer machine has the same size, beautiful shape, sharp edges and no residue.

9. Excellent design, easy operation, can quickly complete the toast slicing operation;

10. The whole machine is laser cut, integrally formed, and has a precise structure; with imported motor and control system, it runs smoothly and without noise at high speed; the outer shell is multi-layer baked varnish, easy to clean and maintain;

Daily maintenance work

1. After starting up, the equipment should be tested with no load. After confirming that there is no abnormality in the equipment, it will start to work formally;

2. Maintain the blade regularly, otherwise it will affect the service life of the equipment;

3. Before shutting down, clean the surface of the conveyor belt and pressure roller.

4. To clean the machine, please wipe it clean with a rag, but do not rinse it with a water pipe;

5. It is strictly forbidden for untrained personnel to operate the machine;

Advantages of choosing wanlisonic

1. Wanlisonic has advanced technology and low equipment scrap rate.

2. Excellent cutting effect, the cutting edge is clean and neat, without edge tissue.

3. Provide consultation and development for the project.

4. The cutting speed is high, the number of replacement blades is small, and the production efficiency is high.

5. The machine runs longer, which improves the work efficiency of Ultrasonic cheesecake and bread slicer machine.

6. Stable quality reduces labor, reduces costs and improves efficiency.

The above is the detailed introduction of the characteristics of wanlisonic Ultrasonic cheesecake and bread slicer machine. If you want to know more about the price, model, size, picture, manufacturer and other information of bread slicer machine, please contact us.

Related Products

Ultrasonic Cheesecake And Bread Slicer Machine