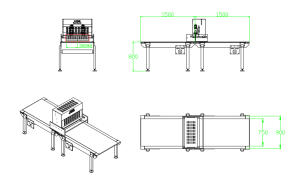

The ultrasonic bread cutting machine precisely slices products with an ultrasonic blade. As a protective measure, a window cap is placed over the blade. This cap has hinged doors with pneumatic shock absorbers facilitating access for cleaning and maintenance purposes. Stainless steel and other non-rusting materials are used for the slicer, which is also built on casters for complete mobility.

In terms of cutting accuracy, its performance is remarkable. The equipment uses an advanced numerical control system that can accurately set the cutting thickness, and the error can be controlled within a very small range. Whether it is making thin slices of delicate French baguettes with a thickness accuracy of 1 – 2 millimeters, or processing thick – cut sandwich bread with a thickness error of no more than ±0.5 millimeters, each slice of bread can ensure a uniform thickness. This not only improves the appearance quality of bread products, but also, for chain bakeries, food processing plants and other enterprises that pursue product standardization, ensures the unified image and stable quality of products in the market, greatly enhancing product competitiveness.

The convenience of equipment operation and maintenance is also a major highlight. The operation interface is designed to be simple and intuitive. Employees can quickly get started after simple training and can easily complete operations such as cutting parameter setting, start – up and shutdown through the operation panel. In terms of maintenance, the overall machine is reasonably structured, and key components are easy to disassemble and replace. Daily cleaning only requires simple wiping and rinsing, greatly reducing the labor and time costs of equipment maintenance and ensuring the long – term stable operation of the equipment.

From commercial bakeries and sandwich shops to large-scale food production facilities, these machines are indispensable for efficiently slicing toasted bread for sandwiches, burgers, and other culinary creations.

1. We have experience in food cutting machine more than 10 years.

2. We offer OEM custom service, produce and process products according to your drawings and requirement.

3. Our ultrasonic cutters have the following characteristics, they do not stick to the knife during operation; they do not deform the food, and the cut surface is very neat.

Model:Wanlisp4-300K1450L2000

Dimensions:2000*W900*H1400mm

Weight:Net Wt.210KGS, Gross Wt.310KGS

Voltage:220V

Rated power:50HZ-60HZ

Frequency:20000Hz

Cutting speed:60 cuts/minute( adjustable)

Number of blades:2(optional)

Blade materials:Titanium Alloy

Wanli Group offers innovative and customized bakery cutting solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your food production.

To reach our anytime via email, please fill out the form below with your request and a company representative will reply to you. To find your local WANLISONIC representative to connect directly click your region in the contact drop down menu.

Contact WANLISONIC For immediate assistance please contact us the corporate headquarters during business hours at 8:00 am – 24:00 pm.

NEWS

Wanli Ultrasonic Gummy Candy Cutting Machine

Wanli Ultrasonic Nougat Candy Cutter

WANLI Ultrasonic Swiss Roll Cutting Machine

Send Your Inquiry Today