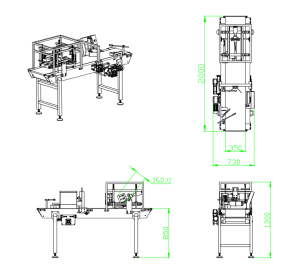

Ultrasonic Sandwich Cake Cutting Machine:

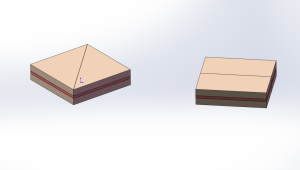

Sandwich Cake

Sandwich Bread

At WANLI, we are proud to radiate our influence to every dessert industry.

Use WANLI. No worries!

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Impedit egestas aliquet?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Sapien class quo temporibus?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Sapien class quo temporibus?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Elementum voluptate sodales?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Elementum voluptate sodales?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Send Your Inquiry

Wanli Group offers innovative and customized bakery cutting solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your food production.

To reach our anytime via email, please fill out the form below with your request and a company representative will reply to you. To find your local WANLISONIC representative to connect directly click your region in the contact drop down menu.

Contact WANLISONIC For immediate assistance please contact us the corporate headquarters during business hours at 8:00 am – 24:00 pm.

Send Your Inquiry Today