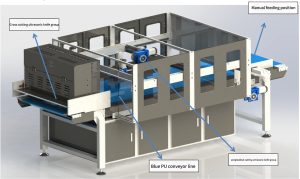

It consists of cutting machine, conveyor belt, and ultrasonic generator, the knife be controlled by the ultrasonic sound, so cutting be quick and cutting surface be tidy, better shape for final goods. Stainless steel structure, easy to clean, serve motor, fast and stable. For automatically cutting cake, bread, nougat, frozen cake, Halva Bar etc. It is the fastest and most convenient type, the cutting cross section will be very tidy and uniform.

Picture this—you’re producing hundreds of Swiss rolls an hour, and every single slice needs to look Instagram-perfect. One mistake? You lose time, product, and maybe a customer. That’s where Wanli’s Ultrasonic Swiss Roll Cutting Machine enters the spotlight.But why ultrasonic? And why Wanli? Let’s dive into how this high-tech, sleek piece of equipment is changing the pastry world—one perfectly cut Swiss roll at a time

Understanding Ultrasonic Cutting:

The Science Behind Ultrasonic Cutting:Ultrasonic cutting uses high-frequency vibrations—usually around 20–40 kHz—to move a titanium or steel blade so fast that it literally slices through food like butter. The ultrasonic energy breaks down resistance, which means:Less pressure is applied No dragging or squishing Super-clean cuts

Step-by-Step Cutting Process:Load the roll onto the conveyor ,Adjust slicing size on the interface ,Blade oscillates at frequency,Swiss roll is sliced uniformly—no crumble, no mess

Blade Oscillation and Clean Separation,Thanks to ultrasonic vibration:Cream stays inside,Sponge stays fluffy,Each piece looks factory-perfect

User-Friendly Operation Interface

Even if you’re not a machine operator, the interface is intuitive:

Multi-language support

Smart alerts

Auto-stop for maintenance

Benefits for Bakeries and Food Manufacturers

Increased Efficiency and Productivity

From commercial swiss roll and sandwich shops to large-scale food production facilities, these machines are indispensable for efficiently slicing toasted bread for sandwiches, burgers, and other culinary creations.

1. We have experience in food cutting machine more than 10 years.

2. We offer OEM custom service, produce and process products according to your drawings and requirement.

3. Our ultrasonic cutters have the following characteristics, they do not stick to the knife during operation; they do not deform the food, and the cut surface is very neat.

Model:Wanlisp4-300K1450L2000

Dimensions:2000*W900*H1400mm

Weight:Net Wt.210KGS, Gross Wt.310KGS

Voltage:220V

Rated power:50HZ-60HZ

Frequency:20000Hz

Cutting speed:60 cuts/minute( adjustable)

Number of blades:2(optional)

Blade materials:Titanium Alloy

Wanli Group offers innovative and customized bakery cutting solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your food production.

To reach our anytime via email, please fill out the form below with your request and a company representative will reply to you. To find your local WANLISONIC representative to connect directly click your region in the contact drop down menu.

Contact WANLISONIC For immediate assistance please contact us the corporate headquarters during business hours at 8:00 am – 24:00 pm.

NEWS

Wanli Ultrasonic Gummy Candy Cutting Machine

Wanli Ultrasonic Nougat Candy Cutter

WANLI Ultrasonic Swiss Roll Cutting Machine

Send Your Inquiry Today