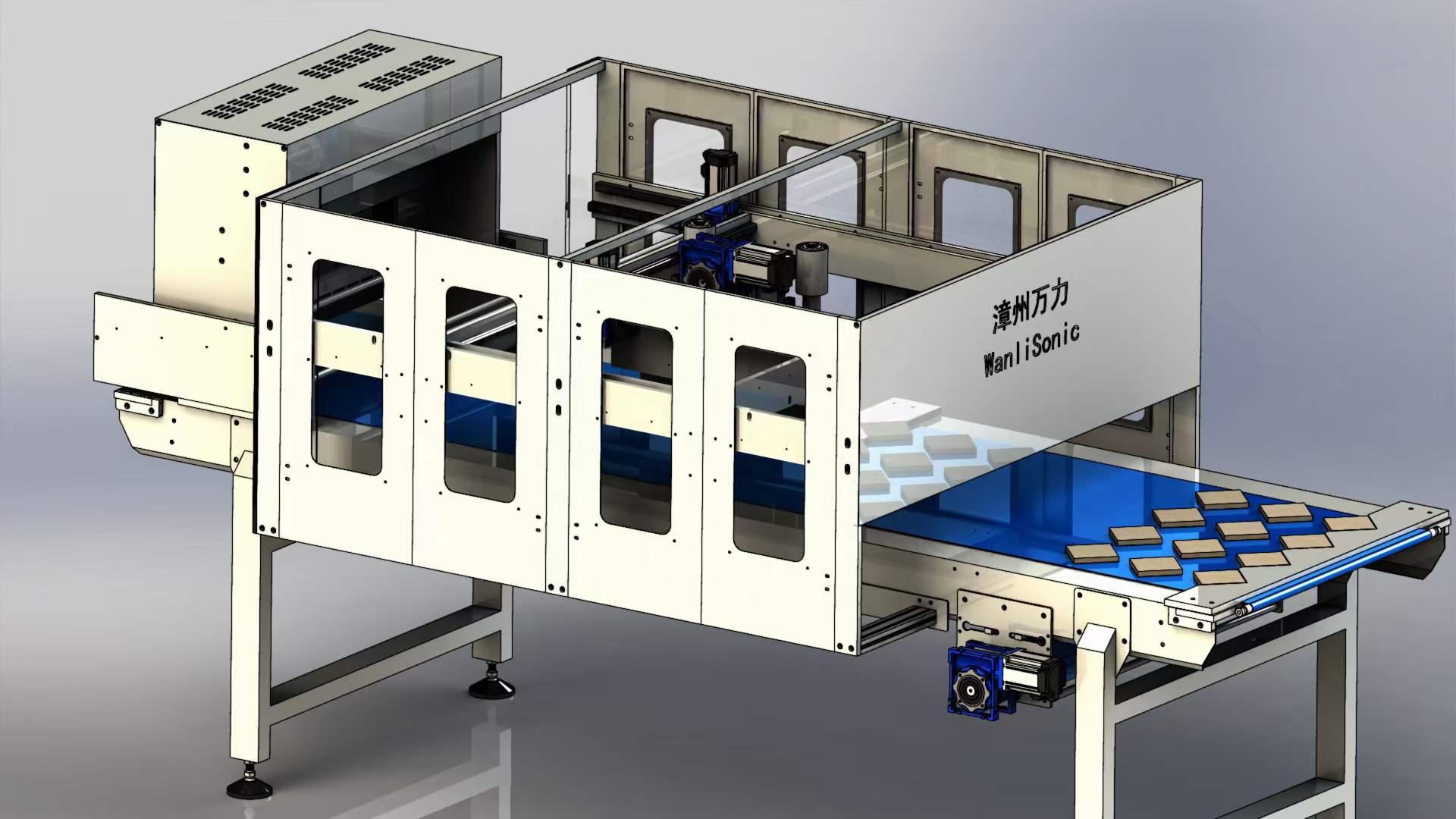

What is Wanli Ultrasonic Sandwich Cutting Machine

In today’s fast-paced food industry, precision and efficiency are key factors for success. One of the standout innovations in food preparation is the Wanli Ultrasonic Sandwich Cutting Machine. Known for its advanced ultrasonic technology, this machine has revolutionized how sandwiches are cut, providing superior speed and accuracy compared to traditional methods. In this article, we’ll explore the benefits, features, and overall performance of the Wanli Ultrasonic Sandwich Cutting Machine.

What is an Ultrasonic Cutting Machine?

An ultrasonic cutting machine uses high-frequency sound waves to generate vibrations that are applied to a cutting tool. These vibrations break down the food’s molecular structure, allowing for clean, precise cuts without exerting much pressure. This method ensures that the sandwich’s ingredients, such as bread, meat, and vegetables, retain their integrity, preventing squashing or tearing.

Benefits of Ultrasonic Cutting:Precision: The high-frequency vibrations enable flawless, straight cuts,Speed: Ultrasonic cutting is faster than traditional cutting methods.

Reduced Waste: Less food is wasted as the cutting process is cleaner and more efficient.

Why Choose Wanli Ultrasonic Sandwich Cutting Machine?

The Wanli Ultrasonic Sandwich Cutting Machine is designed to handle the unique requirements of sandwich cutting. Unlike standard cutters that may crush or distort soft ingredients like lettuce or tomato, the Wanli ensures each ingredient remains intact and perfectly cut.

Features of the Wanli Machine:Advanced Ultrasonic Technology: Provides ultra-fine cuts that traditional machines can’t achieve.Versatility: Can cut various types of sandwiches, from simple to complex multi-layered ones.Durability: Built with high-quality materials that ensure longevity and continuous operation in busy kitchens.

How Does the Wanli Ultrasonic Sandwich Cutter Work?|

The process begins with ultrasonic waves being generated by the machine’s transducer, which is attached to a cutting blade. The blade vibrates at a high frequency, slicing through the sandwich with minimal force. The result is a clean, smooth cut, even through difficult ingredients like soft bread or delicate fillings.

Step-by-Step Cutting Process:

Loading: Sandwiches are placed on the conveyor belt or platform.

Vibration Activation: The ultrasonic transducer activates, sending sound waves to the blade. Cutting: The blade makes a clean, fast slice through the sandwich.

Output: The sandwich pieces are neatly separated and ready for serving or packaging.Advantages of Using Wanli Ultrasonic Sandwich Cutting Machine

When it comes to cutting sandwiches, precision is key. The Wanli Ultrasonic Sandwich Cutter provides several advantages over traditional cutting methods.

Speed and Efficiency

The Wanli can cut multiple sandwiches per minute, making it an ideal solution for high-volume kitchens or catering services. With reduced processing time, more sandwiches can be prepared, increasing overall efficiency.

Clean, Precise Cuts

Unlike traditional knives or rollers that may crush or distort sandwiches, the Wanli ensures each sandwich is cut cleanly and evenly, preserving the freshness of all ingredients.

Preservation of Ingredients

One of the most notable benefits of ultrasonic cutting is the preservation of delicate ingredients, like lettuce, tomatoes, and cheese. These ingredients remain intact, ensuring a fresh, high-quality sandwich every time.

Types of Sandwiches the Wanli Machine Can Cut

The Wanli Ultrasonic Sandwich Cutter is highly adaptable, capable of cutting a wide range of sandwich types. Whether you’re preparing simple single-layer sandwiches or complex multi-layered creations, this machine can handle it all with precision.

Energy Efficiency of the Wanli Ultrasonic Cutter

The Wanli Ultrasonic Sandwich Cutter is designed to be energy-efficient, reducing energy consumption compared to traditional cutting machines. The ultrasonic technology uses less power, making it an eco-friendly option that doesn’t compromise performance.

Safety Features of the Wanli Ultrasonic Sandwich Cutter

Safety is a top priority, especially in busy kitchen environments. The Wanli Ultrasonic Cutter comes with built-in safety features to ensure safe operation for all users.

Key Safety Features:

Automatic Shutoff: Prevents accidents by shutting off if a malfunction is detected.

User Protection: The cutting mechanism is shielded to prevent accidental contact with the blade. |

Routine Cleaning:

Clean the ultrasonic transducer and blades after each use.

Regularly check the machine for any wear or tear.

Applications of the Wanli Ultrasonic Sandwich Cutter in Various Industries

The Wanli Ultrasonic Sandwich Cutter is not just for restaurants; it’s a valuable tool in various food industries.

Key Applications:

Restaurants & Food Chains: Efficient sandwich production for high customer demand.

Bakeries & Catering Services: Ideal for cutting sandwiches for events.

Fast-Food Chains & Cafeterias: High-volume sandwich production in a short amount of time.

Comparing Wanli with Other Ultrasonic Cutting Machines

When compared to other ultrasonic cutting machines, the Wanli Ultrasonic Sandwich Cutter stands out for its affordability, ease of use, and versatility. Other machines may offer similar features, but Wanli offers the best combination of price and performance.

How to Choose the Right Ultrasonic Cutter for Your Business

Before purchasing an ultrasonic cutting machine, consider factors like volume requirements, sandwich types, and budget.

The Wanli Ultrasonic Sandwich Cutter is perfect for businesses looking for a reliable and cost-effective solution to streamline their sandwich production.

The Wanli Ultrasonic Sandwich Cutting Machine offers a unique and efficient solution to sandwich production. With its advanced ultrasonic technology, precision cutting, and energy efficiency, it’s a top choice for businesses.