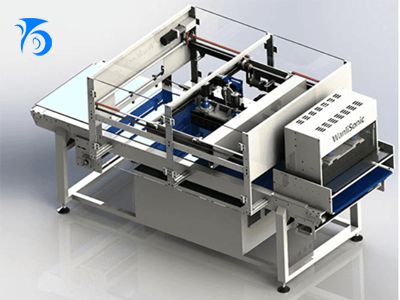

Wanlisonic Ultrasonic Sponge Cake Cutter

Imagine slicing a soft sponge cake with a regular knife—crumbs everywhere, uneven slices, and cream sticking to the blade. Frustrating, right? That’s where the Wanlisonic Ultrasonic Sponge Cake Cutter comes in. Designed with high-frequency vibrations, this advanced machine ensures clean, uniform, and smooth slices every time. No more messy cuts—just perfect portions that look as good as they taste.

Understanding Ultrasonic Cutting Technology|

So, how does it work? Ultrasonic cutting uses high-frequency sound waves to vibrate a blade thousands of times per second. Instead of tearing through the cake, the blade gently slices it with almost no resistance. Think of it as cutting through butter with a hot knife—effortless and clean. Unlike traditional knives, ultrasonic blades don’t squash or deform delicate textures, making them ideal for sponge cakes.

Why Sponge Cakes Need Special Cutting

Sponge cakes are known for their soft, airy texture. While delicious, they’re a nightmare to cut evenly. Standard knives often leave ragged edges, press down the cake, or smear cream layers. With ultrasonic cutting, bakeries can maintain the fluffiness, structure, and presentation of sponge cakes—perfect for professional display.

Key Features of Wanlisonic Ultrasonic Sponge Cake Cutter

High-frequency vibration blades – Glide through sponge without resistance.

Non-stick slicing – Cream, chocolate, or jam won’t cling to the blade.

Adjustable portion control – Get precise slices, whether square, round, or triangular.

Hygienic stainless steel design – Built for food safety and easy cleaning.

Operator safety mechanisms – Includes shields and automatic shut-off for secure use

How It Works

The process is simple yet innovative:

Place the sponge cake on the cutter’s platform.

Set the desired portion size.

The ultrasonic blade activates with micro-vibrations.

In seconds, the cake is divided into perfectly even slices.

Depending on the model, bakers can choose semi-automatic operation for flexibility or fully automatic systems for mass production.

Benefits for Bakeries

For bakery owners, the Wanlisonic cutter is a game changer. It delivers:

Consistent portioning – Every slice looks identical

Time-saving efficiency – Cuts faster than manual methods.

Reduced waste – Clean cuts mean minimal crumbling.

Enhanced presentation – Professional-looking slices attract more customers.

Advantages for Industrial Baking

Large-scale bakeries love this cutter because it handles high-volume production without compromising on quality. With customizable cutting patterns and options for integration into production lines, Wanlisonic ensures efficiency while reducing manual labor costs.

Comparison: Ultrasonic vs. Traditional Cutters

Precision: Ultrasonic blades deliver flawless cuts, while knives often tear.

Cleaning: Traditional knives need frequent cleaning; ultrasonic blades resist sticking.

Cost: The initial investment is higher, but long-term ROI from efficiency and reduced waste makes it worthwhile.

Applications Beyond Sponge Cakes

The versatility doesn’t stop at sponge cakes. The Wanlisonic cutter is perfect for:

Mousse cakes – Maintaining smooth layers.

Cheesecakes – Preventing cracks during slicing.

Frozen desserts – Cutting without defrosting.

Pastries and bread – Achieving precise cuts without crushing.

User Experience and Reviews

Professional bakers rave about how much time and effort this machine saves. Case studies show bakeries doubling their efficiency while improving customer satisfaction thanks to uniform, professional slices.

Maintenance and Cleaning

The cutter is designed with food-grade stainless steel, making it easy to wipe down after use. Regular blade inspections and ultrasonic cleaning cycles ensure long-lasting durability.

Safety Features

Safety is a priority. The Wanlisonic cutter includes:

Automatic shut-off when idle.

Protective casings around the blade.

Emergency stop buttons for extra control.

Customization Options

From small countertop models for boutique bakeries to large automated units for industrial use, Wanlisonic offers custom sizes and cutting patterns to match production needs.

Investment Value

Yes, the upfront cost may feel steep, but think of it as an investment. With faster production, reduced waste, and improved presentation, bakeries often see a quick return on investment. Small bakeries especially benefit, as the cutter allows them to compete with larger players.

Future of Ultrasonic Cutting in Baking

The future looks exciting. With growing demand for precision-cut desserts and efficiency in production, ultrasonic cutting will likely expand into chocolate shaping, artisan bread slicing, and even frozen food preparation.

The Wanlisonic Ultrasonic Sponge Cake Cutter is more than just a machine—it’s a revolution in baking. By combining precision, speed, and hygiene, it helps bakeries of all sizes deliver beautiful, uniform slices that customers love. Whether you’re running a small patisserie or a large industrial bakery, this cutter is the ultimate upgrade.