Wanlisonic Ultrasonic Roll Cake Cutting Machine

Cake cutting might sound simple, but in the commercial baking world, it’s a fine art. When you’re producing thousands of roll cakes every day, you can’t afford ragged edges, smudged cream, or uneven portions. This is where ultrasonic cutting technology changes the game.

What is Ultrasonic Cutting?

Ultrasonic cutting uses high-frequency vibrations (usually around 20–40 kHz) applied to a specially designed blade. This vibration reduces friction, so the blade glides through soft, sticky, or delicate foods without squashing or tearing them.

Why it’s Revolutionizing the Bakery Industry

For bakeries, this means cleaner cuts, less waste, and happier customers. Presentation matters, and with ultrasonic cutting, every slice looks as perfect as the first.

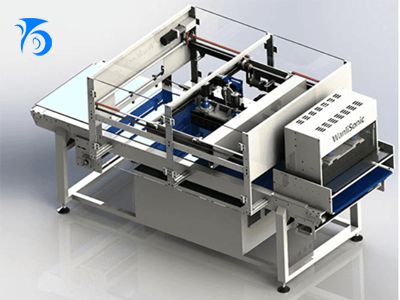

Overview of WANLISP2-250K800L3500 Model

Machine Name and Specifications:The WANLISP2-250K800L3500 is Wanlisonic’s powerhouse for cutting roll cakes. It’s engineered for high-volume production lines, ensuring speed without sacrificing precision.

Design and Build Quality:Built from stainless steel with food-grade components, this machine is designed for durability, hygiene, and compliance with international food safety standards.

Key Features of the WANLISP2-250K800L3500

High-Precision Ultrasonic Blades

The heart of the machine is its ultrasonic blade, which vibrates at optimal frequencies to deliver perfectly smooth cuts.

Consistent, Clean Cuts for Roll Cakes

Whether you’re slicing chocolate Swiss rolls or matcha cream rolls, the result is always uniform.

Adjustable Cutting Parameters

Operators can easily adjust speed, slice thickness, and blade vibration to suit different recipes.

Energy Efficiency

Despite its power, the WANLISP2-250K800L3500 consumes minimal electricity, making it both eco-friendly and cost-effective.

How It Works:Ultrasonic Vibration Mechanism

The blade oscillates thousands of times per second, reducing contact resistance and heat generation.

Automated Cutting Process

Simply load the roll cakes, set your parameters, and let the machine do the rest — no manual effort required.

Benefits for Commercial Bakeries

Increased Production Speed:Faster cutting means you can meet high demand without bottlenecks.

Reduced Waste:Precision cuts mean minimal product loss — every slice is saleable.

Better Product Presentation

Clean edges enhance the look of your cakes, which is vital for premium brands.

Application Beyond Roll Cakes

Cutting Mousse Cakes:Soft and airy mousse stays intact during slicing.

Slicing Cheesecakes:Dense cheesecakes are cut without cracking.

Portioning Brownies and Fudge:Even sticky treats come out neat and tidy.

Technical Specifications Size and Dimensions

Large enough for industrial needs but compact enough to fit in most bakery layouts.

Power and Voltage Requirements

Compatible with standard industrial power setups.

Blade Frequency and Amplitude

Optimized for bakery products, ensuring versatility across recipes.

Installation and Setup Guide

Space Requirements:Ensure enough clearance for loading and unloading trays.

Safety Precautions:Operators should wear protective gloves and follow lockout/tagout procedures during maintenance.

Calibration Steps

Follow the included guide to align and test the blade before full production.

Maintenance Tips:

Cleaning the Ultrasonic Blade,Wipe down after each shift with approved food-safe cleaning agents.Checking Electrical Components,Regular inspections prevent downtime.

Replacing Wear PartsOrder genuine Wanlisonic parts for the best performance.

Cost and Return on Investment (ROI)

Pricing Overview:While it’s a premium investment, it pays for itself through efficiency gains.

Long-Term Savings:Less labor, less waste, and faster turnaround translate into significant savings.

Comparison with Traditional Cake Cutting Machines

Speed and Accuracy,Ultrasonic machines outpace traditional blades in both speed and quality.

Labor Savings,Automation reduces the need for manual cutting.

Consistency,Every slice is identical, making packaging and presentation easier.

Future Trends in Ultrasonic Food Cutting

Smart Automation Integration;Expect future models to integrate with AI-driven quality control systems.

Eco-Friendly Manufacturing:More sustainable materials and lower energy consumption are on the horizon.

The Wanlisonic Ultrasonic Roll Cake Cutting Machine WANLISP2-250K800L3500 is more than just a cutter — it’s a production accelerator, a quality enhancer, and a waste reducer. For bakeries aiming to scale while maintaining impeccable quality, it’s a game-changer.