Wanlisonic Ultrasonic Rice Cake Cutter

Rice cakes are a favorite snack across cultures, but anyone who has tried slicing them knows the struggle—sticky textures, crumbly edges, and uneven shapes. The Wanlisonic Ultrasonic Rice Cake Cutter solves this problem by using high-frequency vibrations to make perfectly clean cuts, without tearing or squishing the product.

What is an Ultrasonic Rice Cake Cutter?

It’s a specialized cutting machine that uses ultrasonic waves to vibrate a blade at tens of thousands of times per second. This frictionless motion allows it to glide through even the stickiest rice cake without leaving residue on the blade.

Why Ultrasonic Cutting is Perfect for Rice Cakes

Rice cakes, especially those with fillings or glutinous rice bases, tend to stick to metal blades. Ultrasonic cutting eliminates this sticking, preserving the cake’s shape and appearance.

Challenges in Cutting Rice Cakes

ticky Texture – Glutinous rice adheres to metal easily.

Chewy Consistency – Dense texture makes smooth cutting difficult.

Shape Loss – Manual cutting often leads to uneven sizes and damaged edges.

Problems with Traditional Cutting Methods

Knives and wire cutters rely on force, which compresses and distorts rice cakes, leading to waste and inconsistent results.

Wanlisonic – Innovating the Food Cutting Industry

Wanlisonic is known for creating ultrasonic cutting equipment designed for bakeries, confectioneries, and snack manufacturers. Their focus on precision and speed has made them a trusted name in the industry.

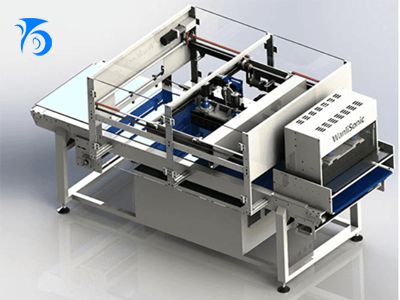

How the Wanlisonic Ultrasonic Rice Cake Cutter Works

The blade vibrates at ultrasonic frequencies (usually around 20–40 kHz), breaking down the cake’s resistance. This allows the blade to slide effortlessly through without pulling or tearing.

The Wanlisonic Ultrasonic Rice Cake Cutter isn’t just about slicing rice cakes—it’s about doing it better, cleaner, and faster. Let’s break down its standout features:

Key Features of the Wanlisonic Ultrasonic Rice Cake Cutter

Adjustable Cutting Parameters for Versatility:Not all rice cakes are the same. Some are soft and airy, others dense and chewy, and many include sticky fillings. The Wanlisonic cutter allows operators to fine-tune vibration frequency, blade speed, and cutting depth to match the exact texture of the product. This means you can switch from slicing glutinous rice cakes to energy bars without needing a completely different setup.

Non-Stick Ultrasonic Blades:The blade’s ultrasonic vibrations create a micro-vibration effect, breaking surface adhesion so sticky rice or fillings don’t cling to the blade. This not only keeps the cut clean but also reduces downtime for cleaning, which is a big plus for high-volume production.

High-Precision, Uniform Slicing:Whether cutting square blocks, rectangular bars, or intricate shapes, the cutter ensures every slice is uniform in size and thickness. This consistency is vital for commercial production where product appearance influences customer buying decisions.

Automated and Manual Operation Modes:Some production lines benefit from full automation, while others prefer manual control for custom shapes and artistic presentation. Wanlisonic offers both options, giving businesses the flexibility to choose based on workflow and production style.

Compact and Industrial Models Available:From small bakeries producing a few trays of rice cakes a day to large snack manufacturers slicing thousands of units per hour, there’s a Wanlisonic model to fit every scale. Compact countertop units are ideal for artisanal producers, while industrial conveyor-based machines handle continuous cutting with minimal operator intervention.

Benefits

Perfect Cuts – No smearing or tearing.

Reduced Waste – Maximizes yield.

Faster Processing – Ideal for high-volume production.

Better Presentation – Uniform slices enhance retail appeal.

Applications Beyond Rice Cakes

This machine also handles mochi, brownies, energy bars, and even soft layered pastries with the same precision.

Step-by-Step Operation Guide

Power on the machine.

Set blade vibration and speed.

Place rice cake blocks on the cutting surface.

Guide or automate the blade through the product.

Clean immediately after use.

Maintenance and Cleaning

The machine’s smooth surfaces make cleaning easy. Regular blade inspection ensures optimal performance, and occasional recalibration keeps cutting precision consistent.

Buying Guide

Consider your daily production volume, available space, and budget. Wanlisonic offers scalable models that fit both artisanal kitchens and large manufacturing lines.

User Reviews

Bakeries and snack companies report shorter processing times and higher-quality product presentation. Many note that customers appreciate the clean, uniform look of their rice cakes.

Comparison with Other Brands

While other brands offer ultrasonic cutters, Wanlisonic is praised for its balance of performance, affordability, and customer support.

Future of Ultrasonic Cutting

Expect future models to feature AI-driven slicing patterns, smart recipe memory, and greener production materials.

The Wanlisonic Ultrasonic Rice Cake Cutter is more than just a machine—it’s a production game-changer. It saves time, reduces waste, and ensures every rice cake looks perfect on the shelf.