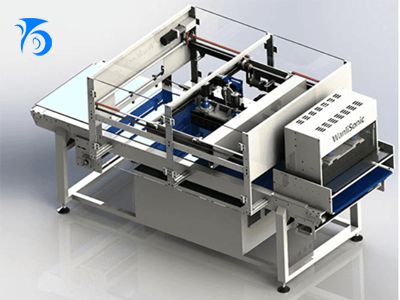

Wanli Ultrasonic Tofu Cutter

Cutting tofu may sound simple, but anyone in food production knows it’s a delicate challenge. Tofu’s soft, sponge-like texture can crumble easily when handled with traditional knives or mechanical slicers. That’s where innovation steps in—the Wanli Ultrasonic Tofu Cutter is designed to transform how tofu is sliced, making the process faster, cleaner, and more precise.

What is the Wanli Ultrasonic Tofu Cutter?

The Wanli Ultrasonic Tofu Cutter is a high-tech machine that uses ultrasonic waves to cut tofu smoothly without crushing or sticking. Unlike traditional blades, its ultrasonic vibrations create a frictionless cut, ensuring tofu maintains its perfect shape. The machine typically includes an ultrasonic generator, transducer, and titanium blade—all engineered for food-grade safety.

How Ultrasonic Cutting Works

At its core, ultrasonic cutting uses high-frequency vibrations (20–40 kHz). These vibrations reduce resistance between the blade and the food, creating a clean slicing motion without tearing. Unlike conventional cutters that rely on force, ultrasonic blades glide through tofu like a hot knife through butter. This process prevents residue buildup and maintains a hygienic cutting environment.

Difference Between Ultrasonic and Traditional Cutting

Traditional cutting: Pressure-based, causes crumbling and sticking.

Ultrasonic cutting: Vibration-based, frictionless, and clean.

Advantages of Ultrasonic Cutting

Reduced cutting force,Non-stick slicing,Faster operation,Consistent product quality

Key Features of Wanli Ultrasonic Tofu Cutter

High Precision Cutting – Delivers uniform tofu cubes or slices every time.

Smooth, Non-Stick Blade – Prevents tofu from sticking to the blade surface.

Hygienic Design – Built with stainless steel, easy to wash and sanitize.

Safety Engineering – Comes with protective measures for operators.

Energy Efficiency – Consumes less power compared to heavy-duty cutters.

Benefits of Using Ultrasonic Cutting for Tofu

Switching to ultrasonic cutting brings tangible benefits:

Consistent Portioning – Each slice is identical, perfect for packaging.

Enhanced Productivity – Cuts faster, saving labor costs.

Reduced Waste – Less crumbling means more sellable product.

Better Presentation – Smooth slices improve shelf appeal.

Applications Beyond Tofu

Applications Beyond Tofu

The Wanli Ultrasonic Cutter isn’t limited to tofu. It also works perfectly for:

Soft cheeses,Cakes and pastries,Jellies and mousses

This versatility makes it a valuable investment for bakeries, tofu factories, and dairy producers.

Comparing Traditional vs. Ultrasonic Tofu Cutting

Manual slicing: Inconsistent, labor-intensive, prone to accidents.

Mechanical cutting: Faster but causes sticking and crumbling.

Ultrasonic cutting: Precise, clean, efficient—designed for modern production.

Technology Behind Wanli’s Innovation

Wanli integrates:

High-Frequency Vibration Systems – For smooth slicing.

Digital Controls – Easy to program for different tofu sizes.

Automation Compatibility – Can be integrated into full production lines

Safety Standards and Compliance

The machine meets food-grade standards, with stainless steel construction, protective covers, and automated shut-off systems. It also complies with international safety regulations, ensuring global usability.

Cost-Effectiveness and ROI

Although ultrasonic cutters are an investment, they pay off with:

Reduced labor expenses,Less product waste,Longer equipment lifespan

Many tofu manufacturers see ROI within months of adoption.

Customer Success Stories

A tofu factory in Asia reported a 30% increase in production efficiency after switching to Wanli’s ultrasonic cutter. Another bakery praised its versatility for cutting mousse cakes and cheesecakes with flawless edges.

Maintenance and Cleaning

Maintenance is simple:

Rinse and sanitize stainless-steel surfaces,Wipe down the ultrasonic blade,Regular checks on generator and transducer,The blade’s durability ensures long service life with minimal upkeep.

How to Choose the Right Ultrasonic Cutter

When choosing, consider:Production volume,Budget,Compatibility with existing production lines

Wanli offers multiple models, making it suitable for both small tofu shops and large-scale manufacturers.

Future of Ultrasonic Cutting in Food Industry

As automation and robotics evolve, ultrasonic cutting will expand beyond tofu and bakery products. Future machines may use AI-driven cutting precision and self-cleaning features, making food production even more efficient.

The Wanli Ultrasonic Tofu Cutter is more than a machine—it’s a leap forward in food technology. With precision cutting, hygienic design, and long-term cost savings, it empowers businesses to deliver high-quality products consistently. Whether for tofu or other soft foods, this innovation is setting a new standard in the industry.