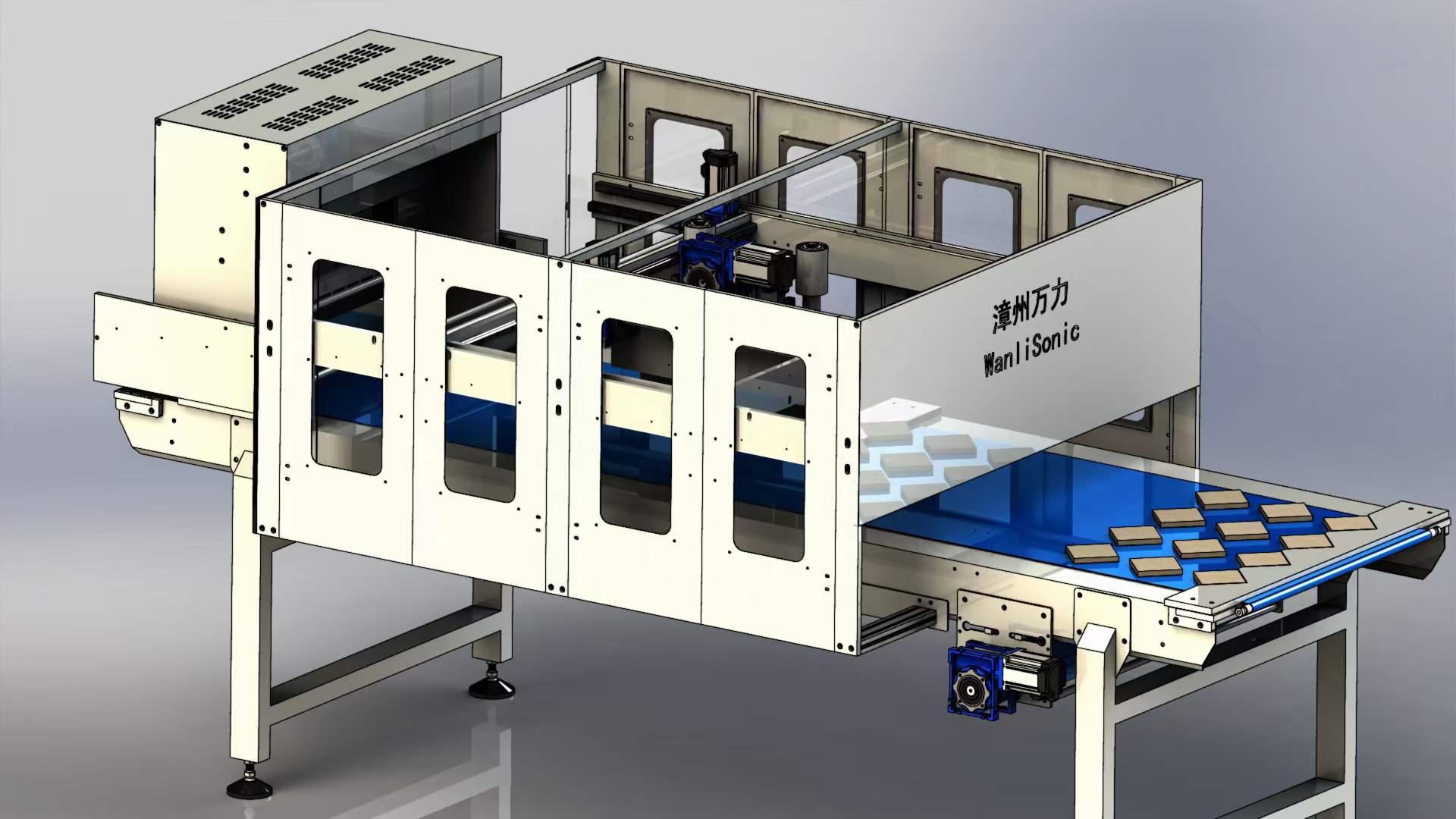

Wanli Ultrasonic Thousand Layer Cake Cutter

Have you ever tried slicing a thousand layer cake only to end up with a squished mess and uneven slices? If yes, then you know how tricky it can be. That’s where Wanli Ultrasonic Thousand Layer Cake Cutter comes in. This advanced machine combines the art of baking with the science of ultrasonic technology, making cake cutting effortless, precise, and beautiful.

Why Precision Matters in Modern Baking

In today’s competitive bakery industry, presentation is everything. Customers don’t just want delicious cakes—they want perfect slices that look as good as they taste. Precision cutting ensures consistent portion sizes, less wastage, and improved customer satisfaction.

The Rise of Ultrasonic Cutting Technology

Ultrasonic cutting isn’t brand new, but its adoption in bakeries has skyrocketed in recent years. Unlike traditional blades, ultrasonic cutters use high-frequency vibrations to glide through food without dragging or tearing. For delicate items like thousand layer cakes, this is a total game-changer.

Understanding the Thousand Layer Cake

What is a Thousand Layer Cake?

A thousand layer cake, often known as lapis legit in Southeast Asia or mille crepe in France, is a dessert made up of multiple thin layers stacked together. Each slice reveals a stunning pattern that looks almost like edible art.

Origin and Cultural Significance

This cake has deep cultural roots, often associated with celebrations, weddings, and festive occasions. Because of its layered texture, it symbolizes prosperity and abundance.

Unique Texture and Challenges in Cutting

The layered structure makes it delicate—cutting with regular knives often results in crumbling edges, smudged layers, and a loss of its beautiful pattern.

The Problem with Traditional Cake Cutting

Messy Edges and Uneven Slices: Standard knives compress layers, ruining the cake’s appearance.

Time-Consuming Manual Labor: Hand cutting large batches is slow and inconsistent.

Loss of Product Quality: When cakes don’t look good, customers lose interest—even if the taste is great.

Introduction to Ultrasonic Cutting Technology

How Ultrasonic Vibration Works

Ultrasonic blades vibrate at a frequency of up to 20,000 Hz, reducing friction so the blade slices cleanly without resistance.

Why Ultrasonic is Ideal for Delicate Desserts

The vibration prevents sticking—great for creamy, sticky, or frozen items. It also ensures precise cuts without damaging the texture.

Benefits Over Mechanical Blades

Cleaner cuts,Less wastage,Higher speed and efficiency,Greater durability

Wanli’s Innovation in Cake Cutting

Wanli has taken ultrasonic cutting to the next level by designing machines specifically tailored for bakeries.

Precision Blades:The blades are designed for smooth entry, reducing deformation of delicate cakes.

Automated Control Systems:With digital control panels, bakers can adjust speed, thickness, and cutting style.

Adjustable Cutting Modes;From straight slices to complex patterns, the cutter can handle it all.

How Wanli Ultrasonic Thousand Layer Cake Cutter Works

Step 1: The cake is placed on the conveyor platform.

Step 2: The ultrasonic blade vibrates at high frequency.

Step 3: The machine automatically slices the cake into uniform portions.

Step 4: Clean slices are ready to be packaged or served.

The entire process is hygienic, fast, and operator-friendly.

Benefits of Using Wanli Ultrasonic Cutter

Perfectly smooth edges every time

Consistency in portion size

Significant reduction in wastage

Increased productivity and profitability

Applications Beyond Thousand Layer Cakes

Wanli’s cutter isn’t limited to mille crepe or lapis legit. It can also handle:

Soft mousse cakes,Cheesecakes and brownies,Frozen desserts,Sticky pastries like mochi or nougat

Comparing Wanli with Other Cutting Solutions

Manual vs Ultrasonic: Manual cutting is slow and messy, ultrasonic is fast and clean.

Semi-Automatic vs Fully Automatic: Wanli offers both options depending on bakery size.

Why Wanli Stands Out: Superior precision, customizable settings, and proven durability.

Cost-Effectiveness and ROI

Though the initial investment may seem high, bakeries quickly recover costs through:

Lower labor expenses,Faster production cycles,Higher product appeal leading to more sales

Maintenance and Durability

Wanli’s machines are built for long-term use. They’re easy to clean, resistant to wear, and supported by professional after-sales service. The ultrasonic blades last significantly longer than traditional ones.

Future of Ultrasonic Cutting in Baking Industry

With AI integration and robotic automation, the future looks even brighter. Soon, bakeries may see fully automated production lines where cakes are baked, sliced, and packaged without human intervention.

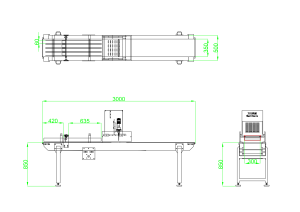

How to Choose the Right Wanli Ultrasonic Cutter

Consider your bakery’s production volume

Decide between semi-automatic and fully automatic models

Explore customization options for size, speed, and cutting style

The Wanli Ultrasonic Thousand Layer Cake Cutter is more than just a machine—it’s a bakery revolution. With its precision, efficiency, and versatility, it empowers bakers to create stunning desserts that delight both the eye and the taste buds. For bakeries looking to stay ahead of the competition, investing in this cutter is a smart, future-ready choice.