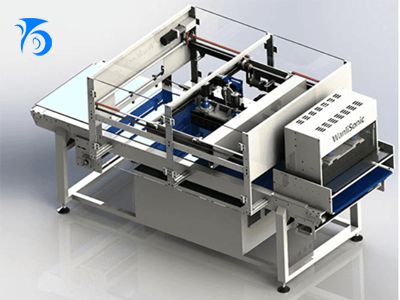

Wanli Ultrasonic Sandwich Cutting Machine

Ever struggled with slicing a sandwich neatly, only to end up with filling spilling everywhere? Imagine that problem multiplied in a large-scale production line. That’s where the Wanli Ultrasonic Sandwich Cutting Machine steps in—offering precision, speed, and clean slicing that keeps every sandwich looking picture-perfect.

What is the Wanli Ultrasonic Sandwich Cutting Machine?

This machine is designed to cut sandwiches using ultrasonic vibrations instead of traditional blades. It’s widely used in commercial kitchens, food factories, and catering businesses, ensuring consistent quality across every slice.

How Ultrasonic Cutting Works

Ultrasonic cutting uses high-frequency vibrations to make the blade glide effortlessly through food. Unlike regular knives that crush or tear layers, ultrasonic blades create smooth, clean cuts without deforming delicate fillings. It’s like slicing through food with a blade of air—precise and frictionless.

Why Sandwiches Require Special Cutting

Sandwiches often have multiple layers—bread, meats, cheese, vegetables, sauces. Cutting them with a regular knife can lead to:

Uneven portions,Smashed fillings,Messy presentation

With ultrasonic cutting, each sandwich keeps its structure, layers, and clean edges intact.

Key Features of Wanli Ultrasonic Sandwich Cutting Machine

High-frequency vibrating blades – Cleanly slice through multiple layers.

Non-stick performance – No sticking of sauces or fillings.

Adjustable portion control – Choose desired shapes and sizes.

Hygienic stainless steel design – Easy to clean, food-safe.

Safety systems – Protective guards and emergency stop buttons.

Step-by-Step Cutting Process

Here’s how the machine operates:

Place sandwiches onto the conveyor or platform.

Select desired cut pattern and size.

Ultrasonic blade activates, slicing with micro-vibrations.

Perfectly portioned sandwiches are ready for packaging or serving

Models vary from semi-automatic for smaller kitchens to fully automated for industrial use.

Benefits for Commercial Kitchens and Food Manufacturers

The machine provides several advantages:

Consistency – Every sandwich looks identical.

Efficiency – Cuts faster than manual labor.

Less waste – Clean cuts reduce crumbling and ingredient loss.

Better aesthetics – Perfect slices improve presentation.

Advantages for Large-Scale Production

For food factories producing thousands of sandwiches daily, the Wanli machine is a game-changer. It integrates with automated production lines, enabling continuous cutting with minimal downtime. Plus, custom cutting patterns allow for innovative sandwich designs.

Comparison: Ultrasonic vs. Traditional Sandwich Cutting

Speed – Ultrasonic is much faster.

Precision – Cleaner cuts without smearing.

Maintenance – Easier cleaning due to non-stick blades.

Cost – Higher upfront, but lower long-term costs thanks to efficiency.

Applications Beyond Sandwiches

The versatility extends beyond sandwiches:

Cakes and pastries – Neat slices without crushing.

Cheese – Smooth cuts with no sticking.

Frozen meals – Cuts without thawing.

Bread and bakery products – Consistent portioning.

Customer Experiences and Reviews

Many businesses report significant improvements:

Cafés highlight faster service during peak hours.

Factories praise reduced labor costs and consistency.

Bakeries enjoy professional-quality presentation with minimal effort.

Maintenance and Cleaning

With its stainless steel build, the machine is quick to clean and maintain. Regular inspections keep the blade sharp and efficient, while automatic cleaning options are available in advanced models.

Safety Features and Compliance

Wanli machines are designed with safety in mind:

Protective covers around blades

Emergency stop systems

Compliance with global food safety standards

Customization and Scalability

Whether you run a small sandwich shop or a large industrial food plant, Wanli offers custom machine sizes and configurations to match your needs. Portion sizes, shapes, and cutting patterns can all be tailored.

Return on Investment (ROI)

Though the initial investment is higher than traditional cutters, the ROI is strong due to:

Reduced labor costs

Faster production times

Less food waste

Enhanced customer satisfaction

The Future of Ultrasonic Food Cutting Technology

Looking ahead, ultrasonic cutting will only grow in popularity as automation continues to transform the food industry. Expect innovations like AI-driven portioning, smart quality control, and even robotic integration in future models.

The Wanli Ultrasonic Sandwich Cutting Machine is revolutionizing how sandwiches are prepared in both small and large-scale operations. By combining precision, speed, and hygiene, it ensures every sandwich is perfectly sliced, enhancing both presentation and productivity.