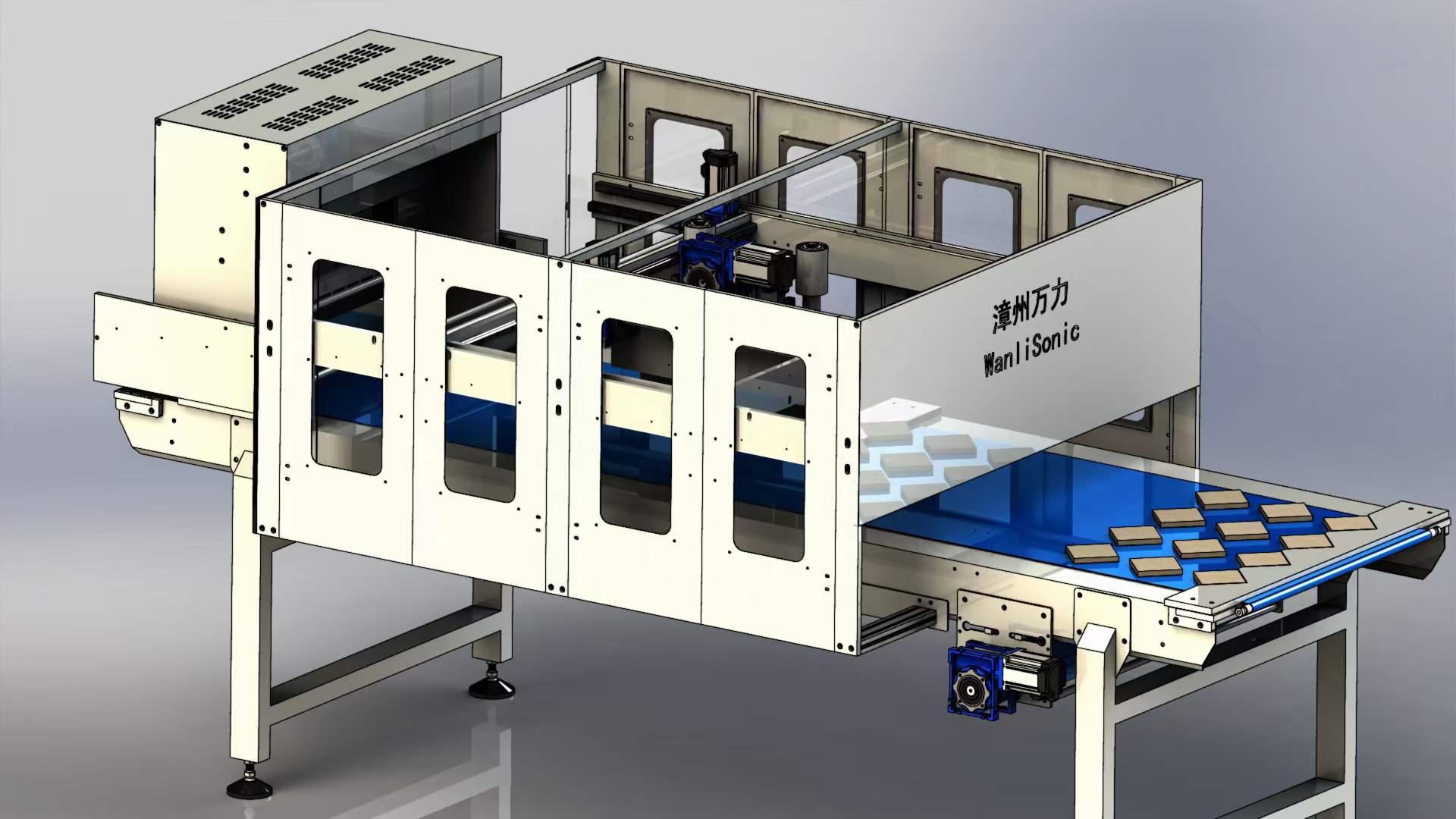

Wanli Ultrasonic Nougat Candy Cutter

Candy lovers know that nougat is as tricky to cut as it is delicious to eat. Sticky, chewy, and often packed with nuts, nougat challenges traditional cutting methods, leaving uneven pieces and messy edges. Enter the Wanli Ultrasonic Nougat Candy Cutter—a breakthrough machine designed to handle these challenges with precision and ease.

What Is an Ultrasonic Nougat Candy Cutter?

This specialized cutter uses ultrasonic vibrations to slice through nougat without sticking, crushing, or deforming it. Unlike steel blades that struggle with nougat’s sticky texture, ultrasonic blades glide through effortlessly, producing clean, consistent pieces.

The Science of Ultrasonic Cutting

At the heart of this technology lies ultrasonic vibration. The blade vibrates at frequencies up to 40,000 times per second, creating a frictionless surface. Imagine cutting honey with a knife that never sticks—that’s what ultrasonic cutting feels like for nougat.

About Wanli

Wanli is a leading manufacturer of ultrasonic food machinery, known for creating reliable, high-quality cutting systems. With a global presence and years of innovation, Wanli has become the go-to brand for bakeries, confectioneries, and food factories seeking cutting-edge technology.

Key Features of Wanli Ultrasonic Nougat Candy Cutter

Precision Cutting – Delivers identical candy pieces every time.

Non-Stick Blades – Handles sticky caramel, honey, and nuts with no residue.

Adjustable Settings – Operators can control slice thickness, speed, and size.

Energy Efficient – Uses less energy than many conventional cutters.

How the Machine Works

Nougat slabs or bars are placed on the cutting line.

The ultrasonic blade vibrates at high frequency,The blade cuts through smoothly, preventing sticking,Finished pieces are uniform and ready for packaging.

Applications in the Confectionery Industry

This machine isn’t just for nougat. It also excels in cutting:

Almond or pistachio nougat bars,Caramel nut candiesChocolate-coated nougat sweetsMulti-layered chewy candies

Why Choose Ultrasonic Cutting for Nougat?

Nougat is notoriously difficult to cut due to its sticky texture and nut-filled composition. Ultrasonic cutting solves this by maintaining the candy’s structure while preserving its chewy bite and glossy finish.

Benefits for Manufacturers

Increased Productivity – Cuts more candies in less time.

Reduced Labor Costs – Minimizes manual cutting needs.

Minimized Waste – No torn or crushed pieces.

Enhanced Presentation – Clean cuts improve product appeal.

Customization Options

Wanli understands that no two candy producers are alike. That’s why their ultrasonic cutter can be customized with different blade lengths, conveyor speeds, and cutting patterns—ideal for both small workshops and large-scale factories.

Comparison: Ultrasonic vs Conventional Cutting

Knives – Get stuck, tear nougat, and require frequent cleaning.

Rotary blades – Struggle with mixed nuts and sticky fillings.

Ultrasonic blades – Slice cleanly, resist sticking, and maintain uniformity.

Maintenance and Cleaning

Maintaining the Wanli ultrasonic cutter is simple. The stainless steel design makes it easy to clean, and routine care involves wiping blades with mild solutions, checking for wear, and ensuring smooth operation.

Safety Standards and Certifications

All Wanli machines are built with food-grade stainless steel and comply with international food safety standards, giving manufacturers peace of mind.

Real-World Case Studie

Candy factories worldwide have seen remarkable improvements after adopting Wanli machines. One manufacturer reported a 40% boost in productivity and significantly reduced waste, while another praised the machine’s ability to handle sticky nougat with zero downtime.

Future of Ultrasonic Cutting in Confectionery

The future looks sweet. As demand for uniform, premium-quality candy rises, ultrasonic cutting will play an even bigger role. We can expect smarter automation, integration with AI systems, and even greater efficiency in the coming years.

The Wanli Ultrasonic Nougat Candy Cutter is more than just a machine—it’s a revolution in candy production. From boosting productivity to ensuring every piece of nougat looks and tastes perfect, this technology is setting new standards in confectionery manufacturing.