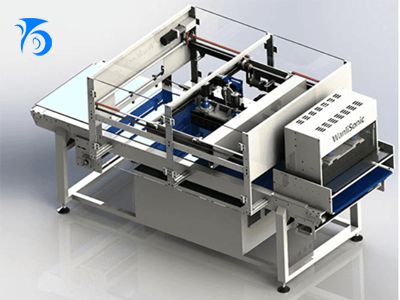

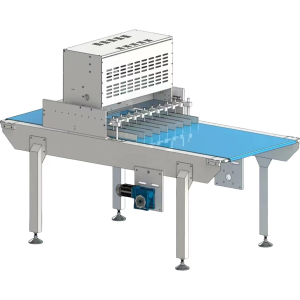

Wanli Ultrasonic Candy Slicing Machine

Imagine slicing candy so precisely that every piece looks identical, with no crumbs, no sticky mess, and no wasted product. That’s exactly what ultrasonic candy slicing delivers. This cutting-edge technology is transforming how confectionery products are made and packaged.

What is the Wanli Ultrasonic Candy Slicing Machine?

The Wanli Ultrasonic Candy Slicing Machine is a specialized piece of equipment designed for confectionery manufacturers. It uses high-frequency ultrasonic vibrations to cut through candies with minimal resistance, ensuring perfect slices every time.

How Ultrasonic Cutting Technology Works

Instead of using brute force like traditional blades, ultrasonic cutters vibrate at extremely high frequencies—typically between 20 kHz and 40 kHz. These vibrations create a friction-reducing effect that allows the blade to glide through even the stickiest sweets effortlessly.

Key Features of the Wanli Ultrasonic Candy Slicing Machine

Precision Cutting Without Deformation

The ultrasonic blade doesn’t squash or warp candy shapes, which is crucial for maintaining a professional product appearance.

Speed and Efficiency in Production

With automated slicing and rapid vibration technology, production lines can achieve higher output with minimal downtime.

Versatility for Different Candy Types

Whether you’re cutting hard candies, fudge, nougat, caramel, or gummies, the machine adjusts to handle varying textures and densities.

Consistency in Slice Thickness

Once calibrated, the machine ensures each slice is identical, improving packaging efficiency and customer satisfaction.

Advantages of Ultrasonic Candy Slicing Over Traditional Methods

Cleaner Cuts Without Sticky Residue

Sticky candies like caramel often gum up regular blades, but ultrasonic slicing leaves blades clean, reducing maintenance interruptions.

Reduction in Product Waste

By minimizing crumbling and sticking, manufacturers save more product, improving their profit margins.

Better Hygiene Standards

Ultrasonic cutting reduces direct contact with products, maintaining a cleaner, safer production environment.

Applications in the Confectionery Industry

Cutting Caramel and Toffee

These dense, sticky sweets benefit most from ultrasonic slicing’s non-stick effect.

Slicing Nougat and Fudge

Soft and crumbly candies like nougat keep their shape without breaking apart.

Perfectly Shaping Jelly and Gummies

Even the most elastic gummy candies can be sliced into perfect pieces without distortion.

Technical Specifications of the Wanli Ultrasonic Candy Slicing Machine

Blade Frequency and Vibration

Operates at ultrasonic frequencies that allow precision slicing without heat damage to candies.

Automation and Control System

Advanced control panels allow easy customization of slice size, speed, and patterns.

Safety Features

Built-in safety sensors and automatic shut-off features protect operators from accidents.

Maintenance and Care Tips

Daily Cleaning Routines

Use food-safe cleaning solutions to remove residue and maintain hygiene.

Periodic Blade Calibration

Ensure the vibration frequency and cutting angles remain optimal.

Troubleshooting Common Issues

Common issues like uneven slicing can often be fixed by adjusting vibration intensity or checking for blade wear.

Cost Efficiency and ROI

Lower Operating Costs:Fewer stoppages for cleaning and reduced waste lower the cost per unit produced.

Long-Term Profitability:The investment pays for itself quickly through higher production output and reduced losses.

Choosing the Right Model for Your Business

Small-Scale vs. Industrial Models

Small candy shops can opt for compact tabletop models, while large factories may need high-capacity industrial slicers.

Customization Options

Wanli offers blade configurations, automation levels, and sizes to suit different production needs.

uture of Ultrasonic Candy Slicing Technology

Integration with AI and Smart Factories

Next-gen machines may use AI to adjust slicing parameters in real time for optimal performance.

Sustainability and Eco-Friendly Designs

Energy-efficient motors and recyclable materials are becoming more common in machine design.

The Wanli Ultrasonic Candy Slicing Machine isn’t just a tool—it’s a game-changer for candy production.This ultrasonic candy cutting machine can do what you need, as long as you enter the program correctly By delivering precision, speed, and cleanliness, it helps confectioners meet modern production demands while maintaining exceptional product quality.