Wanli Ultrasonic Candy Cutter Machine: A Complete Guide

If you’ve ever walked into a candy shop and admired those perfectly sliced caramels, toffees, and chocolate bars, there’s a good chance they weren’t cut by hand. Instead, machines like the Wanli Ultrasonic Candy Cutter are behind that precision. This innovative piece of equipment uses ultrasonic technology to slice through even the stickiest and toughest candy with ease.

So, why should confectioners worldwide be paying attention to this technology? Let’s break it down.

How Ultrasonic Cutting Technology Works

The Science of Ultrasonic Vibrations

At its core, ultrasonic cutting involves a blade vibrating at an extremely high frequency—usually tens of thousands of times per second. This vibration reduces resistance, meaning the blade doesn’t crush or tear the candy but glides right through.

Advantages Over Traditional Cutting Methods

Unlike conventional blades, which often stick to caramel or squash soft fillings, ultrasonic blades cut cleanly and consistently.

Clean Cuts Without Residue

The vibration prevents candy from sticking to the blade, which is a common headache in candy production.

Increased Efficiency and Consistency

Because every cut is uniform, manufacturers can deliver a professional, reliable product every single time.

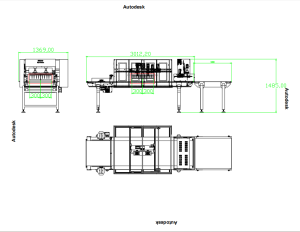

Key Features of the Wanli Ultrasonic Candy Cutter Machine

High-Frequency Vibration Blade

The blade vibrates at ultrasonic speeds, ensuring smooth slicing through sticky or hard-textured sweets.

Precision and Uniformity in Portioning

Every piece of candy is cut to the exact same size, which is essential for packaging and customer satisfaction.

Easy-to-Clean Stainless Steel Body

Wanli machines are built with hygienic stainless steel, making cleaning quick and efficient.

Safety Mechanisms for Operators

The machine comes with protective designs to prevent operator accidents, ensuring both efficiency and workplace safety.

Benefits for the Confectionery Industr

Perfect Cuts for Sticky and Delicate Candies

Think caramel, nougat, and fudge—these often stick to blades. Wanli ultrasonic cutters make slicing them effortless.

Reduced Waste and Product Loss

Smooth cutting reduces crumbling and sticking, which means less product ends up wasted.

Faster Production with Minimal Downtime

With reduced cleaning requirements and faster cutting speeds, production lines keep running smoothly.

Applications of Wanli Ultrasonic Candy Cutter

Cutting Caramels and Toffees

Sticky textures? No problem—ultrasonic vibrations prevent sticking.

Shaping Chocolate Bars and Nougat

Perfectly portioned bars and nougat blocks enhance presentation and packaging.

Portioning Gummy Candies

The machine handles gummies without squishing or stretching them.

Specialty Candies with Nuts and Fillings

Even candies with mixed textures—like chocolates filled with nuts or fruit—are cut cleanly.

Why Choose Wanli Machines for Candy Manufacturing

Innovation and Engineering Excellence

Wanli is recognized globally for pushing boundaries in ultrasonic cutting technology.

Customization for Different Candy Types

Machines can be adjusted for different candy textures, shapes, and sizes.

Proven Reliability in Global Markets

Many confectionery businesses worldwide rely on Wanli equipment for its durability and precision.

Comparison with Conventional Candy Cutting Methods

Mechanical Blades vs Ultrasonic Blades

Traditional blades dull quickly and stick to candies, while ultrasonic blades stay sharp and clean.

Cost-Effectiveness in the Long Run

Although the initial investment is higher, reduced waste and improved efficiency save money over time.

Consistency and Hygiene Differences

Ultrasonic cutters provide hygienic, consistent results that mechanical methods can’t match.

Maintenance and Care Tips

Regular Cleaning Practices

Cleaning is easy due to the non-stick nature of ultrasonic blades, but regular sanitation is still essential.

Blade Care and Replacement

Blades last longer than traditional ones but should be inspected regularly.

Safety Checks Before Operation

Routine inspections keep both operators and products safe.

Customer Success Stories

Small Confectionery Shops

Local candy makers benefit from the professional finish and reduced manual labor.

Large-Scale Candy Manufacturers

Factories use Wanli machines to maintain mass production without compromising quality.

The Future of Candy Cutting Technology

Integration with Automation

Future models will integrate seamlessly with automated packaging and production lines.

AI and Smart Monitoring for Precision Cutting

Artificial intelligence will allow machines to self-adjust for perfect portioning every time.

The Wanli Ultrasonic Candy Cutter Machine isn’t just another piece of confectionery equipment—it’s a game-changer. From sticky caramels to delicate gummies, it ensures precision, speed, and hygiene. For candy makers, big or small, investing in Wanli’s ultrasonic technology means fewer headaches, less waste, and happier customers.