Ultimate Guide to Wanlisonic Ultrasonic Thousand Layer Cake Cutting Machine

Ultimate Guide to Wanlisonic Ultrasonic Thousand Layer Cake Cutting Machine

Cutting a thousand layer cake is no joke. With its thin, delicate layers stacked high and filled with creamy textures, slicing it cleanly can be a real challenge. That’s where the Wanlisonic Ultrasonic Thousand Layer Cake Cutting Machine comes in — a game-changer in precision bakery cutting.

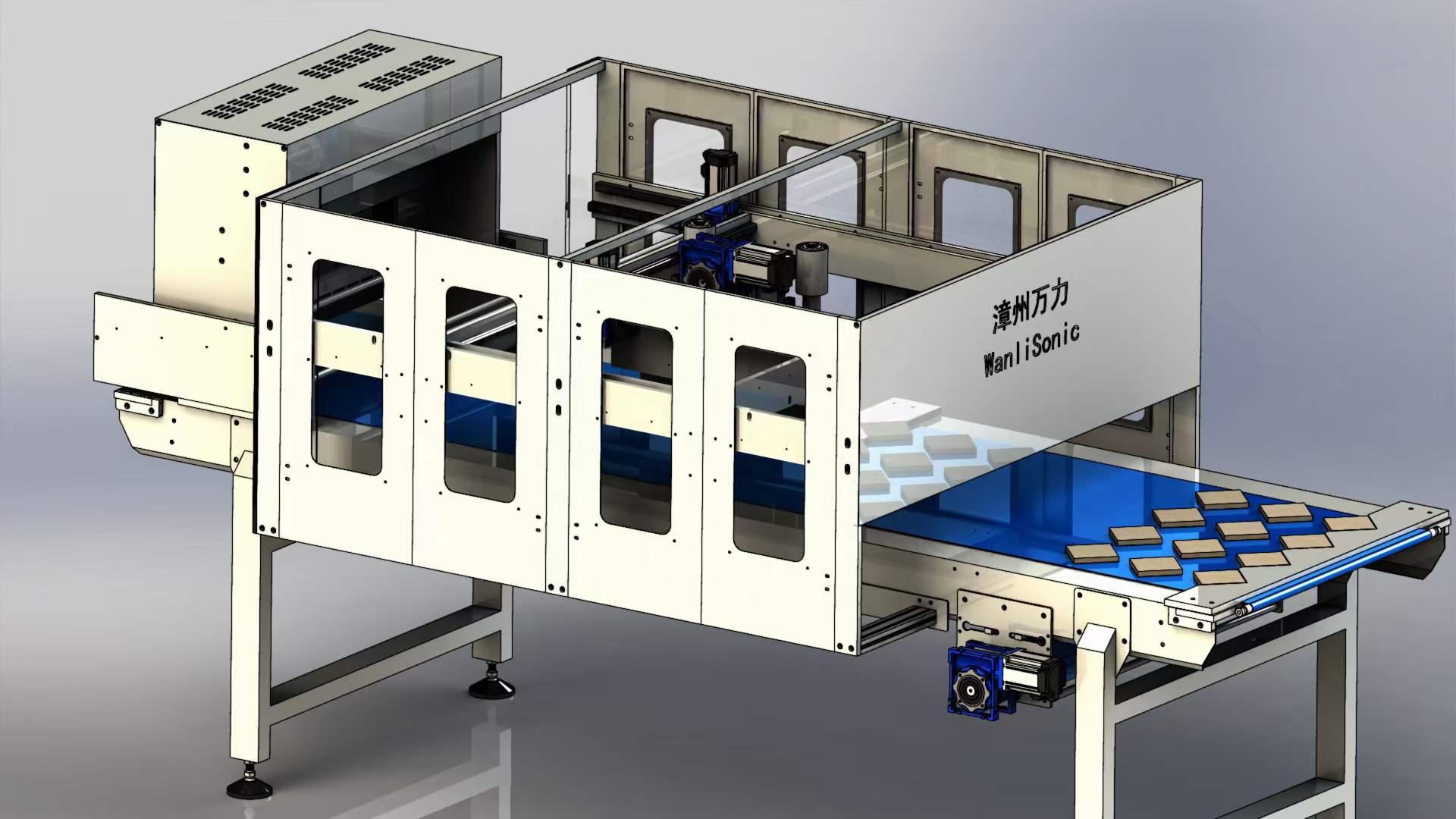

Meet the Wanlisonic Ultrasonic Cutting Machine

Overview of Wanlisonic Brand:Wanlisonic is known for pioneering ultrasonic food processing equipment. With a focus on innovation, efficiency, and hygiene, they’ve developed specialized machines that meet the high demands of commercial bakeries worldwide.

Unique Features for Thousand Layer Cakes

Thousand layer cakes require precision due to their structure — layer upon layer of pastry or crepe alternated with fillings. Wanlisonic’s machine is designed with this exact application in mind, offering smooth, exact cuts without damaging the cake’s shape or texture.

Ultrasonic Technology Explained

What Is Ultrasonic Cutting:Ultrasonic cutting uses high-frequency vibrations — typically around 20kHz to 40kHz — to vibrate a blade. This vibration reduces friction and allows for clean slicing through soft or sticky materials.

How It Works

The blade vibrates tens of thousands of times per second. As it contacts the cake, the ultrasonic energy breaks down resistance at the cutting point, slicing cleanly without pressure.

Benefits Over Traditional Cutting

No smearing of fillings

No blade sticking

Higher consistency

Less downtime due to cleaning

Key Features of the Wanlisonic Ultrasonic Cutter

Precision and Clean Cuts:Each slice is exactly measured, leaving no room for uneven pieces. This is crucial for product presentation and portion control.

No Deformation or Mess:Even soft fillings or fragile layers retain their structure. Your cake stays picture-perfect from oven to plate.|

High-Speed Operation:The machine can process multiple cakes in minutes, greatly improving workflow for busy bakeries.

Smart Control Panel:Adjust parameters like cutting speed, blade vibration frequency, and portion size via a user-friendly interface.

Benefits of Using Ultrasonic Cutting for Thousand Layer Cakes

Maintaining Aesthetic Presentation

Nobody wants a mashed or tilted slice. Ultrasonic cutting ensures every piece looks

Handling Delicate Textures,Whether it’s creamy mousse or buttery pastry, this cutter doesn’t squash or smear.Reducing Waste:No more misshapen or crumbled edges that need to be discarded.Enhancing Production Efficiency:Quick, consistent cuts mean your bakery can keep up with demand — especially during holidays and events.

Materials and Components:Food-Grade Stainless Steel Blades,Durable, rust-resistant, and easy to clean — perfect for hygiene standards.

Vibration System

The core ultrasonic technology sits in a transducer that converts electrical energy into mechanical vibrations.

Safety Mechanisms

Built-in sensors stop the machine immediately if any abnormalities are detected, ensuring operator safety.

Applications Beyond Thousand Layer Cakes

The machine is versatile enough for:Cheesecake,Swiss rolls,Brownies,Ice cream cakes,Mousse-based desserts,So if you bake more than one type of treat, this machine pulls double duty.

How the Machine Works Step-by-Step

Load the Cake: Place it on the cutting tray or conveyor belt.Set Parameters: Choose portion sizes, layer counts, and speed.Start Cutting: Ultrasonic blade gets to work.Collect Finished Product: Cleanly sliced portions are ready for packaging or plating.

Easy Maintenance and Cleaning

Non-Stick Blade Properties:The vibrating blade naturally resists sticking. Cleanup is minimal even after long use.

Simple Disassembly:No need for specialized tools. Take apart the machine quickly for deep cleaning.

Technical SpecificationsDimensions: Customizable (based on model)

Integration with Bakery Production Lines

The Wanlisonic machine can be integrated into conveyor-based production lines, offering full automation and synchronized operations.

Customization Options:Blade Size and Shape Variants

Depending on your cake’s size or shape (round, square, triangle), Wanlisonic provides blade customization options.

Custom Software Settings:Personalize slicing patterns, cutting depths, and rotation functions with software updates.

Cost-Efficiency and ROI

Sure, there’s an upfront investment. But:

Less product waste

Lower labor cost

Faster output

Massive savings over time.

You’ll likely recover your investment within months.

If you’re serious about your bakery business, especially when it comes to complex desserts like thousand layer cakes, investing in the Wanlisonic Ultrasonic Cutting Machine is a no-brainer. It combines tech innovation with precision, giving you unmatched efficiency, cleaner results, and a leg up on the competition.