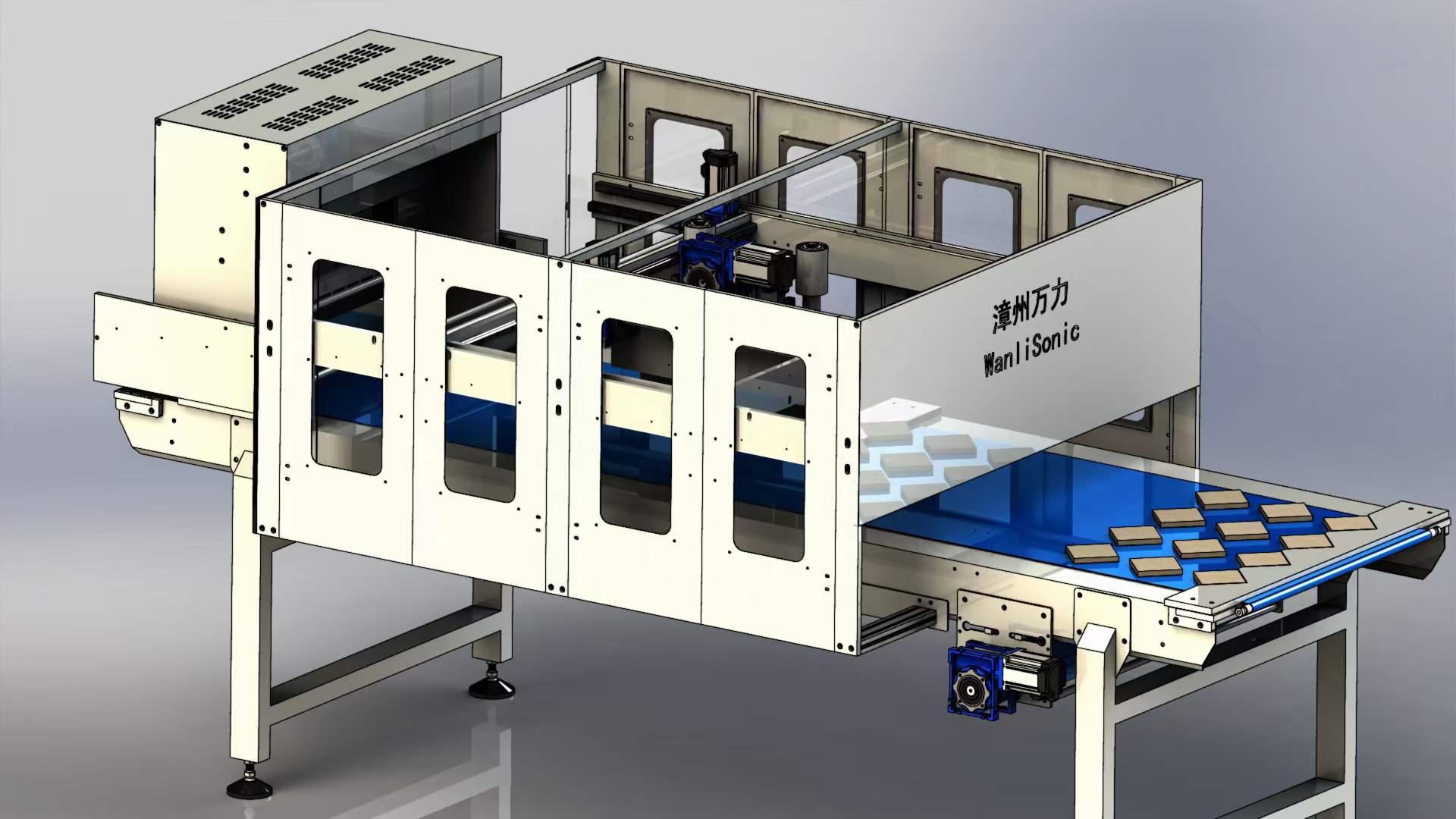

Ultrasonic Cheese Cutter

I bring you a super new gadget – ultrasonic cheese cutter, which will definitely open your eyes! In daily life, cheese is very difficult to cut. Cheese is sticky and soft. If you use an ordinary knife to cut it, it will either be deformed or crooked, and it is easy to stick to the knife, which is very annoying. In addition, the cut cheese is of different sizes and does not look good. However, once the ultrasonic cheese cutter appears, the problem we faced before is very simple. When the ultrasonic cheese cutter starts working, the high-frequency vibration energy acts on the cheese accurately, and the cutting process is extremely smooth. It can cut the cheese cleanly and neatly, and the cut is neat and smooth. The cheese will not deform or stick, and each piece perfectly maintains its original shape. It can be cut into small pieces for easy sharing, or it can be cut into different shapes to make creative food.

Our ultrasonic cheese cutter can easily cope with it. The cut cheese is uniform in size and regular in shape, just like the hands of a professional dessert chef. This wonderful collision of high technology and traditional food is really amazing! Click on the video to witness the magical moment of ultrasonic cutter cutting cheese. I believe that after watching it, you will be attracted by its charm and can’t help wanting to try it! For some food processing factories, using ultrasonic cutting machines to cut cheese can greatly improve production efficiency and ensure the consistency of product quality. Not only does it make the cutting process easy and interesting, it can also instantly improve the appearance of cheese and the cutting advantages are very significant. In terms of cutting accuracy, it is the top level in the industry. It can accurately control the cutting thickness. Whether it is a delicate cheese slice as thin as 2-3mm or a thicker cheese block, the thickness error of each cut can be controlled within a very small range to ensure that the thickness of each slice of cheese is uniform.

For commercially sold cheese products, this high-precision cutting ensures the consistency of product appearance and greatly enhances the competitiveness of the product in the market. For example, when making a French cheese platter, different types of cheese need to be cut into small pieces of consistent size and thickness. The ultrasonic cheese cutter can easily achieve this, giving the platter a perfect visual effect.

The ultrasonic cheese cutter has a very wide range of applications. For cheese manufacturers, it can be used for cutting various types of hard cheese (such as Parmesan cheese) and soft cheese (such as mozzarella cheese). It can not only achieve non-fragmentation cutting of hard cheese, but also solve the problem of easy stringing and adhesion when cutting soft cheese, ensuring product quality while improving production efficiency. When cheese retailers display and sell cheese, they use ultrasonic cheese cutters to cut cheese on site, which can accurately provide customers with cheese blocks of the required thickness and size, improving customer shopping experience. In the catering industry, whether it is a Western restaurant making exquisite cheese dishes, or a pizza shop cutting mozzarella cheese for pizza making, ultrasonic cheese cutters can play their advantages of precise and efficient cutting, providing strong guarantees for the quality of dishes.

Zhangzhou Wanli ultrasonic cheese cutter has become an ideal choice for the cheese processing industry with its excellent cutting accuracy, efficient production capacity, good hygienic cleaning characteristics and wide adaptability to application scenarios. It not only improves the quality and efficiency of cheese processing, but also injects new vitality into the development of the industry, helping enterprises stand out in the fierce market competition.