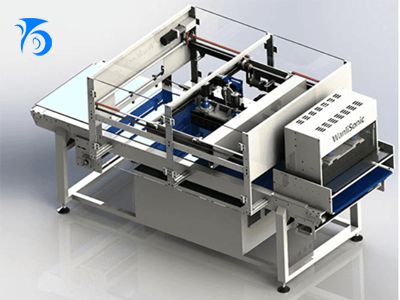

The Complete Guide to the Wanlisonic Ultrasonic Sandwich Cutting Machine

Revolutionizing Sandwich Cutting with Ultrasonic Technology

In today’s fast-paced food industry, efficiency and precision are crucial. Enter the Wanlisonic Ultrasonic Sandwich Cutting Machine, a cutting-edge solution that has changed the game for sandwich production lines. This machine is not just another piece of kitchen equipment; it is an innovative advancement in food processing that offers a perfect cut every time. Whether you’re a restaurant owner, food manufacturer, or caterer, understanding the benefits and functionality of this machine can transform your operations.

What is the Wanlisonic Ultrasonic Sandwich Cutting Machine?

The Wanlisonic Ultrasonic Sandwich Cutting Machine utilizes high-frequency ultrasonic vibrations to slice through food materials smoothly and cleanly. Unlike traditional cutting methods, which rely on mechanical pressure or heated blades, this machine uses ultrasonic waves to create a near-frictionless cutting process. This technology results in a cleaner, more efficient cut, especially for delicate ingredients like bread and fillings that are prone to crushing or squashing.

Why Choose Ultrasonic Cutting Over Conventional Methods?

1. Precision and Clean Cuts

Traditional sandwich cutters often result in uneven cuts, especially when dealing with soft ingredients. The ultrasonic cutting process ensures precision with smooth, clean edges, preserving the integrity of the sandwich and the fillings.

2. Increased Efficiency

Ultrasonic cutting is faster than conventional methods. The high-frequency vibrations reduce the need for excessive force, allowing the machine to cut through multiple sandwiches in a fraction of the time.

3. Minimal Waste

Since ultrasonic cutting minimizes crushing, there’s less waste in the form of crushed bread or fillings. This efficiency not only saves money but also ensures that each sandwich is as presentable as the last.

Key Features of the Wanlisonic Ultrasonic Sandwich Cutting Machine

1. High-Quality Materials

The Wanlisonic machine is built with durable, food-safe materials that ensure longevity and ease of cleaning. This robust construction also prevents the buildup of crumbs or food residue, making the machine more hygienic.

2. Adjustable Cutting Settings

Different sandwiches require different cuts. The machine features adjustable settings that allow users to customize the cutting size, shape, and style based on their specific needs. Whether you prefer square, triangle, or even custom-shaped sandwiches, the machine can deliver.

3. Touchscreen Control

A modern touchscreen interface makes operating the machine simple and intuitive. Users can easily adjust settings, monitor cutting speed, and track machine performance in real-time.

Energy Efficient

Unlike traditional machines that consume large amounts of power, the ultrasonic technology used by the Wanlisonic machine is more energy-efficient, reducing operational costs in the long run.

How Does the Ultrasonic Cutting Technology Work?

Ultrasonic cutting technology works by generating high-frequency sound waves, typically in the range of 20-40 kHz. These sound waves are transmitted through a specialized cutting blade, which vibrates at a very high speed. The ultrasonic waves disrupt the molecular structure of the sandwich, allowing the blade to pass through effortlessly without compressing the ingredients.

This results in precise, clean cuts, with minimal friction and heat generated during the process. As a result, the sandwich maintains its texture and freshness, providing a high-quality end product.

Applications of the Wanlisonic Ultrasonic Sandwich Cutting Machine

1. Commercial Kitchens and Restaurants

In commercial kitchens, speed and consistency are paramount. The Wanlisonic Ultrasonic Sandwich Cutting Machine increases production capacity without sacrificing quality. It’s perfect for high-volume operations that require cutting sandwiches to order or in bulk.

2. Sandwich Manufacturers

For businesses that specialize in pre-packaged sandwiches, this cutting machine offers a way to streamline the production process. With its ability to cut sandwiches with precision, manufacturers can deliver products that meet both consumer expectations and safety standards.

How to Operate the Wanlisonic Ultrasonic Sandwich Cutting Machine

Operating the Wanlisonic Ultrasonic Sandwich Cutting Machine is straightforward. Here’s a step-by-step guide to using the machine effectively:

Prepare the Sandwiches: Arrange the sandwiches neatly on the feeding platform.

Select the Cutting Parameters: Use the touchscreen interface to set your desired cutting size and shape.

Start the Cutting Process: Press the start button to initiate the ultrasonic cutting process. The machine will cut the sandwiches with speed and precision.

Collect the Finished Sandwiches: Once the cutting is complete, collect the sandwiches from the collection tray. They will be neatly cut and ready for packaging or serving.

Benefits of Using the Wanlisonic Ultrasonic Sandwich Cutting Machine

1. Improved Sandwich Presentation

Clean, precise cuts ensure that every sandwich looks perfect, which is crucial for both retail and catering environments. The high-quality cuts enhance the visual appeal, making your sandwiches more attractive to customers.

2. Reduced Product Damage

Traditional cutting methods often crush or squish the ingredients, especially soft fillings. With ultrasonic cutting, there’s minimal force applied, preserving the quality and texture of the sandwich.

3. Higher Customer Satisfaction

Since the cutting process produces consistent, high-quality results, customers are more likely to be satisfied with their sandwiches, leading to positive reviews and repeat business.

Why the Wanlisonic Ultrasonic Sandwich Cutting Machine is a Game-Changer

The Wanlisonic Ultrasonic Sandwich Cutting Machine is a revolutionary tool for anyone in the food production industry. It combines speed, efficiency, and precision, making it the ideal choice for high-volume sandwich production. Its unique ultrasonic cutting technology ensures minimal waste, reduced product damage, and consistently perfect cuts.

By investing in this machine, you’ll not only improve the quality of your products but also streamline your operations, saving time and energy in the process.