Advantages and Product Features of Zhangzhou Wanli’s Round Cake Cutting Machine

Advantages and Product Features of Zhangzhou Wanli’s Round Cake Cutting Machine

The automated process makes the cutting take only 17 seconds, and the robot cell ensures a perfect cut every time.

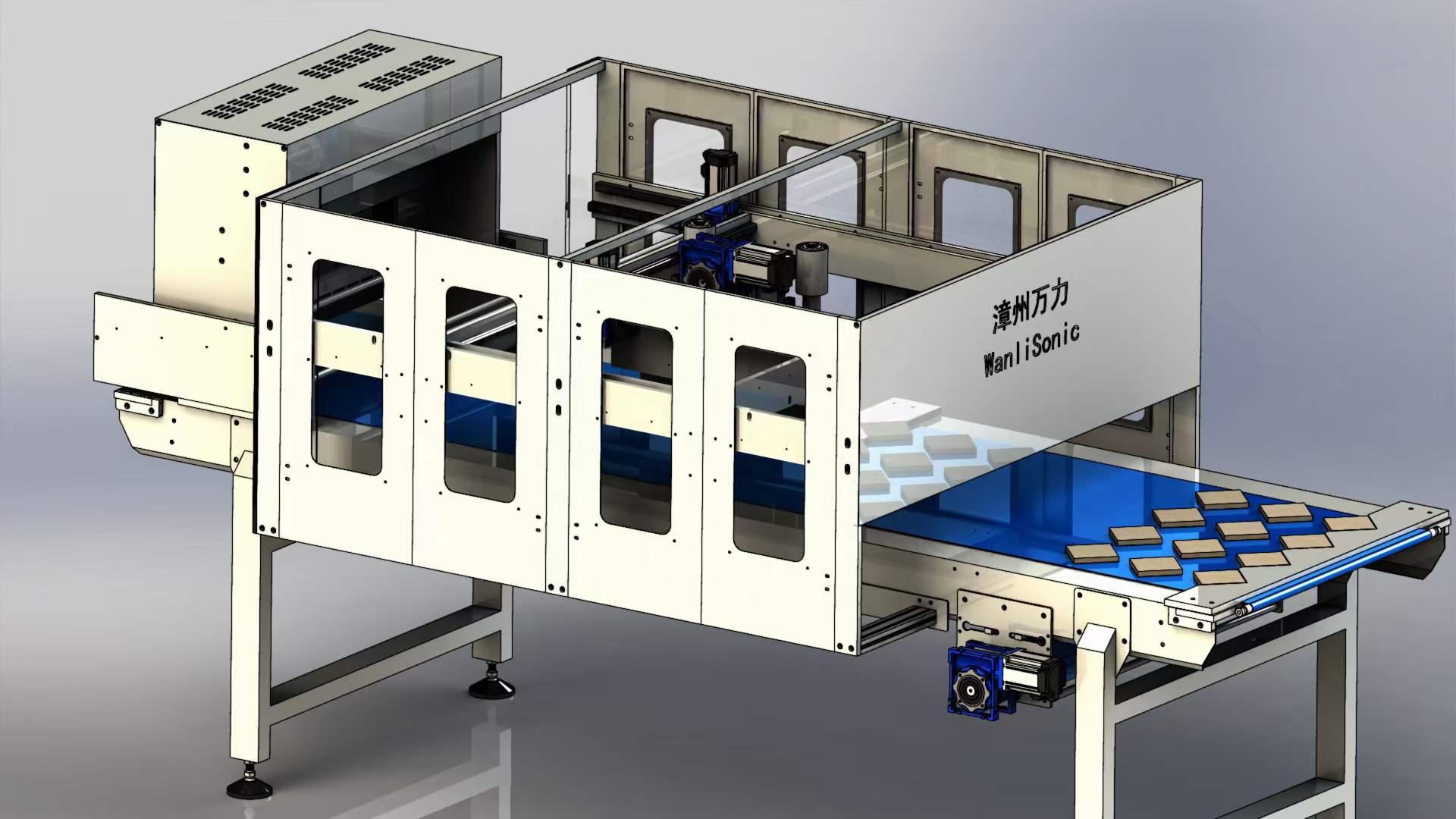

Zhangzhou Wanli’s round cake cutting machine holds significant advantages in the baking equipment field with cutting-edge technology and innovative design, and its product features meet the diverse needs of enterprises of different scales.

Zhangzhou Wanli is a leading manufacturer of portioning equipment in the baking industry, focusing on the processing of fresh and frozen desserts. Since 2014, its equipment has been used for cutting, slicing and portioning cheesecakes, pies, layer cakes, loaves, butter, cheese, pizzas, sandwiches and other kinds of food

In terms of technical advantages, the ultrasonic cutting system equipped in this cutting machine can be regarded as an industry innovation. Since its application, it has helped enterprises achieve a 600% increase in production capacity, a data that intuitively reflects its high efficiency. The ultrasonic technology, combined with Teflon-coated blades, can perform ultra-fine cutting on round cakes, solving the problems of easy crumbing and deformation in traditional cutting.

The blade passes through an oil reservoir before cutting to ensure a smooth cutting surface, which greatly improves the appearance quality of the product and meets the strict requirements of high-end baking for exquisiteness.Automation and intelligence are another major highlight. The fully automated process compresses the cutting time of a single portion to 17 seconds, and with the robot unit, it realizes “zero error” operation. Regardless of the production scale, the cutting accuracy of each cake can be guaranteed to be consistent, which not only reduces the uncertainty of manual operation but also lowers labor costs, allowing enterprises to stably maintain product quality while improving efficiency.

In terms of product features, Zhangzhou Wanli’s round cake cutting machine shows strong adaptability. Its models cover online and offline applications, and the production speed can be flexibly adjusted between 80 and 1500 cakes per hour. It can not only meet the small-batch production needs of start-up bakeries but also adapt to the high-speed assembly lines of large commercial factories. The newly launched offline models are more innovative. Some models are equipped with divider inserts between slices, which further optimizes the cutting quality, makes the product display more attractive, and enhances the competitiveness in the terminal market.