Not only non-woven and textile fabrics, but also various foods can be precisely and cleanly separated or cut by ultrasound.

Depending on application, cutting can be performed vertically, horizontally or continuously with the appropriate sonotrode design. Sonotrodes used as cutting tools suffer comparatively low wear. Because they are cold, as in the case of ultrasonic welding and punching, a wide variety of materials can be efficiently processed. Examples of this in the food industry are various types of cheese, bakery products and confectionery, dough or deep frozen products. The respective sonotrodes divide the food precisely with the help of ultrasonic oscillations. Cutting itself is due to the reduced force required by the vibration of the cutting tool easier than with conventional knives. The foods are therefore not deformed by compression or squashing.

Not only non-woven and textile fabrics, but also various foods can be precisely and cleanly separated or cut by ultrasound,Depending on application, cutting can be performed vertically, horizontally or continuously with the appropriate sonotrode design. Sonotrodes used as cutting tools suffer comparatively low wear. Because they are cold, as in the case of ultrasonic welding and punching, a wide variety of materials can be efficiently processed. Examples of this in the food industry are various types of cheese, bakery products and confectionery, dough or deep frozen products. The respective sonotrodes divide the food precisely with the help of ultrasonic oscillations. Cutting itself is due to the reduced force required by the vibration of the cutting tool easier than with conventional knives. The foods are therefore not deformed by compression or squashing.

Our ultrasonic cutting blades, ultrasonic knifes, ultrasonic horns or sonotrodes are increasingly used in the food industry within food processing machines either for ultrasonic cutting, ultrasonic slicing, ultrasonic portioning or ultrasonic dicing food such as : cheese slicing, pastry cutting, cake portioning, pie slicing, servings cutting, deli portioning, meat cutting, bacon slicing or even frozen food cutting.

1. Bakery industry

2.Bread industry

3.cake industry

4.Bean products industry

5.food industry

• Fully Stainless steel construction & food grade plastics

• A function of sterilization with UV light

• Remote access capability with Ethernet

• Safety protective grating

• Motor-driven rotary ultrasonic blade

• Easy-to-use editing programs

• 3 user login levels-operator, supervisor and technician

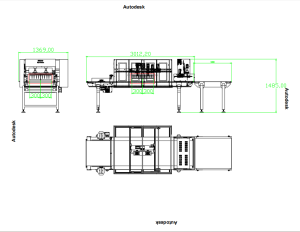

Model Wanlisp4-300K900L3500

Material Titanium Alloy

Ratde Voltage 220V

Frequency 50HZ

Power 5000W

Can be controlled by touch screen Yes

Condition New

For dicing or slicing bread and cakes.The length of the whole machine is 3.5M(divided into 2 sections). Width is 0.9M.Equipped with material rotating device.Can cut size:600mm*600mmCutting speed 60 times/minuteThe full set of action is driven by the Servo Motor.

Wanli Group offers innovative and customized bakery cutting solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your food production.

To reach our anytime via email, please fill out the form below with your request and a company representative will reply to you. To find your local WANLISONIC representative to connect directly click your region in the contact drop down menu.

Contact WANLISONIC For immediate assistance please contact us the corporate headquarters during business hours at 8:00 am – 24:00 pm.

NEWS

Wanli Ultrasonic Gummy Candy Cutting Machine

Wanli Ultrasonic Nougat Candy Cutter

WANLI Ultrasonic Swiss Roll Cutting Machine

Send Your Inquiry Today