Automatic Ultrasonic Dough Cutting Machine

Traditional industry: Traditional cutting uses a knife with a sharp edge to press against the material being cut. This pressure is concentrated at the edge of the blade, the pressure is very large, exceeding the shear strength of the dough, the dough is cut off. Since the dough is pulled apart by strong pressure, the cutting edge of the cutting tool should be very sharp, and the dough itself must be under relatively high pressure. Not good for cutting sticky dough.

Ultrasonic dough cutting equipment: The principle of ultrasonic dough cutting equipment is completely different from traditional cutting. It uses the energy of ultrasonic wave to heat and melt the material to be cut locally, so as to achieve the purpose of cutting the material. Therefore, the ultrasonic dough cutting equipment does not need a sharp edge, nor does it require a lot of pressure, and will not cause chipping, damage, and deformation of the material being cut. At the same time, due to the ultrasonic vibration of the cutting knife, the friction resistance is particularly small, and the cut dough is not easy to stick to the blade.

Traditional industry: Traditional cutting uses a knife with a sharp edge to press against the material being cut. This pressure is concentrated at the edge of the blade, the pressure is very large, exceeding the shear strength of the Swiss Roll , the Swiss Roll is cut off. Since the Swiss Roll is pulled apart by strong pressure, the cutting edge of the cutting tool should be very sharp, and the Swiss Roll itself must be under relatively high pressure. Not good for cutting sticky Swiss Roll .

Ultrasonic Swiss Roll Cutting Machinet: The principle of Ultrasonic Swiss Roll Cutting Machinet is completely different from traditional cutting. It uses the energy of ultrasonic wave to heat and melt the material to be cut locally, so as to achieve the purpose of cutting the material. Therefore, the Ultrasonic Swiss Roll Cutting Machinet does not need a sharp edge, nor does it require a lot of pressure, and will not cause chipping, damage, and deformation of the material being cut. At the same time, due to the ultrasonic vibration of the cutting knife, the friction resistance is particularly small, and the cut Swiss Roll is not easy to stick to the blade.

Precision Cutting:Ultrasonic bread cutting machines offer unparalleled precision, allowing bakeries to produce uniform slices with razor-sharp edges.

Increased Efficiency:By eliminating the need for manual slicing, ultrasonic bread cutting machines can significantly increase production efficiency, allowing bakeries to meet high demand without sacrificing quality.

Reduced Product Waste:Traditional bread cutting methods often result in significant product waste due to uneven slices and crumbling. Ultrasonic cutting minimizes waste by producing clean, uniform slices with minimal loss

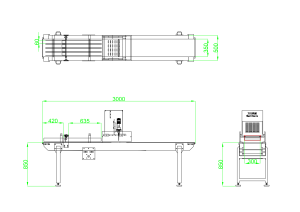

Model:Wanlisp1-250K300L1200

Dimensions:L1200*W300*H1400mm

Weight:Net Wt.170KGS.Gross Wt.300KGS

Voltage:220V

Rated power:3000W

Frequency:50Hz-60Hz

Cutting speed:120 cuts/minute( adjustable)

Number of blades:1

Blade materials:Titanium Alloy

Blade size:300mm(optional)

Wanli Group offers innovative and customized bakery cutting solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your food production.

To reach our anytime via email, please fill out the form below with your request and a company representative will reply to you. To find your local WANLISONIC representative to connect directly click your region in the contact drop down menu.

Contact WANLISONIC For immediate assistance please contact us the corporate headquarters during business hours at 8:00 am – 24:00 pm.

NEWS

Wanli Ultrasonic Gummy Candy Cutting Machine

Wanli Ultrasonic Nougat Candy Cutter

WANLI Ultrasonic Swiss Roll Cutting Machine

Send Your Inquiry Today