For porous foods, such as bread, cakes, marshmallows, and similar structures, the common feature is the void cavernous structure. Moreover, it is easy to be compressed and deformed. If traditional cutting tools are used, only part of the cutting can be achieved. If further cutting, distortion or breakage will be formed. But if you use ultrasonic cutting you get a very good result.

For porous foods, such as bread, cakes, marshmallows, and similar structures, the common feature is the void cavernous structure.Moreover, it is easy to be compressed and deformed. If traditional cutting tools are used, only part of the cutting can be achieved. If further cutting, distortion or breakage will be formed.But if you use ultrasonic cutting you get a very good result.Because ultrasonic cutting can reduce the friction caused by the cutting process, the cutting can be completed with a very small cutting force.The result is a neat, smooth cut surface.Compared with the cutting of dense material, friction has less influence on the cutting process of porous material.Because the actual contact area between the cutter and the material is much smaller than the geometric area of the material.In addition, porous materials require more energy than dense materials in the process of feeding the tool into the material.

Ultrasonic cutting reduces friction, zero pressure cutting processing mode.

The cutting surface is neat and smooth without deformation.

Automatically use conveyor belt to cut food, saving manpower.

Respond to market consumer needs, food hygiene.

Dimensional accuracy: plus or minus 1mm.

The control system can be set to automatic mode, jog debugging mode, the operation is simple and clear; password system protection.

Baking industry

cake industry

Bread industry

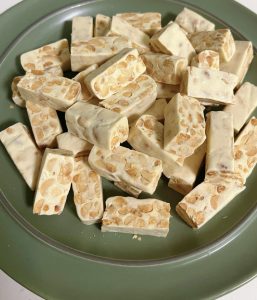

Candy industry

Enhanced Accuracy for Irregular Products:Even unevenly spaced items are sliced with millimeter precision.

Reduced Human Intervention:Less need for manual repositioning, saving labor time.

Consistent Slice Quality:No matter how the product enters, the slice remains perfect.

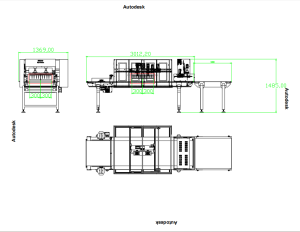

Model:Wanlisp4-300K900L3500

Dimensions:L3000*W1400*H1600mm

Weight:Net Wt. 500KGS, Gross Wt.600KGS

Voltage:220V

Rated power:5000W

Frequency:50Hz-60Hz

Cutting speed:Cross cutting 60 cuts/minute, slitting 30 cuts/minutes

Blade materials:Titanium Alloy

Material of machine frame:Stainless Steel

Wanli Group offers innovative and customized bakery cutting solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your food production.

To reach our anytime via email, please fill out the form below with your request and a company representative will reply to you. To find your local WANLISONIC representative to connect directly click your region in the contact drop down menu.

Contact WANLISONIC For immediate assistance please contact us the corporate headquarters during business hours at 8:00 am – 24:00 pm.

NEWS

Wanli Ultrasonic Gummy Candy Cutting Machine

Wanli Ultrasonic Nougat Candy Cutter

WANLI Ultrasonic Swiss Roll Cutting Machine

Send Your Inquiry Today