The dough is a non-porous and compact structure. In the traditional dough cutting process, it often generates a lot of friction. The friction is related to the viscosity of the material. Ultrasonic Dough cutting can reduce the interaction force between the tool and the material during the cutting process, thereby avoiding plastic deformation. On the other hand, the energy consumption of this compact and non-porous structure during the dough cutter process also increases significantly.

The Candy is a non-porous and compact structure. In the traditional Candy cutting process, it often generates a lot of friction. The friction is related to the viscosity of the material. Ultrasonic Candy cutting can reduce the interaction force between the tool and the material during the cutting process, thereby avoiding plastic deformation. On the other hand, the energy consumption of this compact and non-porous structure during the Candy cutter process also increases significantly.

Consistent, Clean Cuts Every Tim,Each slice looks the same—smooth, intact, and picture-perfect. That’s a big win for customer satisfaction and visual appeal.Reduction in Waste and Crumbles,You won’t lose slices to crumble or tear. That means more sellable product and less thrown in the trash.Higher Output with Less Labor,One operator can do what used to take a full team. And faster, too.Improved Aesthetics for Retail Presentation,Want to impress customers in a glass display case? You need flawless slices—and this machine delivers.

1.cake industry

2.Baking industry

3.Bread industry

4.Candy industry

1.Faster Slicing Speeds,Say goodbye to slow hand-cutting. This machine can process dozens of cakes in a fraction of the time.

2.Lower Operator Fatigue,No more repetitive wrist strain or long hours hunched over a cutting board.

3.Seamless Integration into Production Lines,It fits well into conveyor-based or manual setups—scalable based on your operation size.

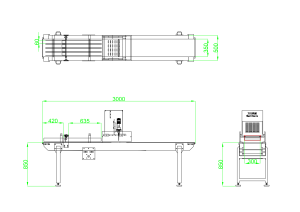

Model:Wanlisp1-250K300L1200

Dimensions:L1200*W300*H1400mm(based on final drawings)

Weight:Net Wt. 170KGS, Gross Wt.300KGS

Voltage:220V

Rated power:3000W

Frequency:50Hz-60Hz

Cutting speed:20-60cuts/minute

Wanli Group offers innovative and customized bakery cutting solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your food production.

To reach our anytime via email, please fill out the form below with your request and a company representative will reply to you. To find your local WANLISONIC representative to connect directly click your region in the contact drop down menu.

Contact WANLISONIC For immediate assistance please contact us the corporate headquarters during business hours at 8:00 am – 24:00 pm.

NEWS

Wanli Ultrasonic Gummy Candy Cutting Machine

Wanli Ultrasonic Nougat Candy Cutter

WANLI Ultrasonic Swiss Roll Cutting Machine

Send Your Inquiry Today