The industrial development of cake slicing has promoted the renewal and innovation of automatic cake slicer equipment. The traditional automatic cake slicer began to fail to meet the market demand and consumers’ aesthetic requirements. The factory began to look for faster and smarter cake slicers with better cutting results. Ultrasonic automatic cake slicer machine was created under such demand.

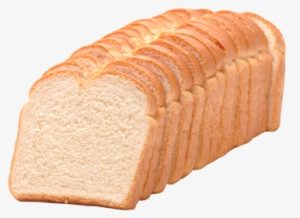

The food industry continually evolves, with advancements focused on improving quality, efficiency, and presentation. Among these innovations, the ultrasonic toast cutting machine stands out for its ability to deliver consistent, clean cuts with remarkable precision. This advanced tool integrates high-frequency vibration technology with cutting-edge design, including a rear pushing plate, making it an essential asset for bakeries and industrial food production lines.

In this blog, we’ll explore how ultrasonic toast cutting machines work, their key features, and the unparalleled benefits they offer in achieving superior slicing performance.

High-Frequency Vibration Technology:At the heart of the machine lies its ultrasonic blade, which vibrates at an incredibly high frequency. This vibration minimizes the force required to cut through toast, ensuring clean, smooth slices every time.

Rear Pushing Plate for Enhanced Stability:The rear pushing plate is a game-changer, holding the toast firmly in place during cutting. This ensures that each slice is of uniform thickness, eliminating any movement or shifting of the bread during the process.

Adjustable Slice Thickness:With customizable settings, operators can adjust the thickness of the slices to suit specific requirements, making it ideal for a variety of applications.

From commercial bakeries and sandwich shops to large-scale food production facilities, these machines are indispensable for efficiently slicing toasted bread for sandwiches, burgers, and other culinary creations.

1. We have experience in food cutting machine more than 10 years.

2. We offer OEM custom service, produce and process products according to your drawings and requirement.

3. Our ultrasonic cutters have the following characteristics, they do not stick to the knife during operation; they do not deform the food, and the cut surface is very neat.

Model:Wanlisp4-300K1450L2000

Dimensions:2000*W900*H1400mm

Weight:Net Wt.210KGS, Gross Wt.310KGS

Voltage:220V

Rated power:50HZ-60HZ

Frequency:20000Hz

Cutting speed:60 cuts/minute( adjustable)

Number of blades:2(optional)

Blade materials:Titanium Alloy

Wanli Group offers innovative and customized bakery cutting solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your food production.

To reach our anytime via email, please fill out the form below with your request and a company representative will reply to you. To find your local WANLISONIC representative to connect directly click your region in the contact drop down menu.

Contact WANLISONIC For immediate assistance please contact us the corporate headquarters during business hours at 8:00 am – 24:00 pm.

NEWS

Wanli Ultrasonic Gummy Candy Cutting Machine

Wanli Ultrasonic Nougat Candy Cutter

WANLI Ultrasonic Swiss Roll Cutting Machine

Send Your Inquiry Today