Cake dough is cut in lines with circular blades after it is cooked. Cream is wiped on on the dough at the bottom. Then the second layer of the cake dough has been put on the other one. Now it is time to cut in the length desired. At this point, there are 2 alternatives. One is traditional blade and the other option is Ultrasonic food slicer with titanium blade. When the cake has cream inside, the unique option is Ultrasonic cutting due to cream adhesion. When the normal blade goes into the cake, the cream sticks to the blade and after 100 pcs, the cream becomes hard on the blade. In the next cuttings, slices the outside is deformed. In order to prevent this sticky cream, Ultrasonic vibrations are used. Because Ultrasonic blade is vibrating while it is slicing so the cream can not stick to the Ultrasonic vibrating blade. As the Ultrasonic blade is made of titanium, it is also suitable for food industry.

As a key equipment in bread production, bakeries, and food processing scenarios, bread cutting machines have their core selling points centered around cutting efficiency, finished product quality, operational convenience, and applicable scenarios. zhangzhouwanli comprehensively optimized the pain points of traditional manual cutting

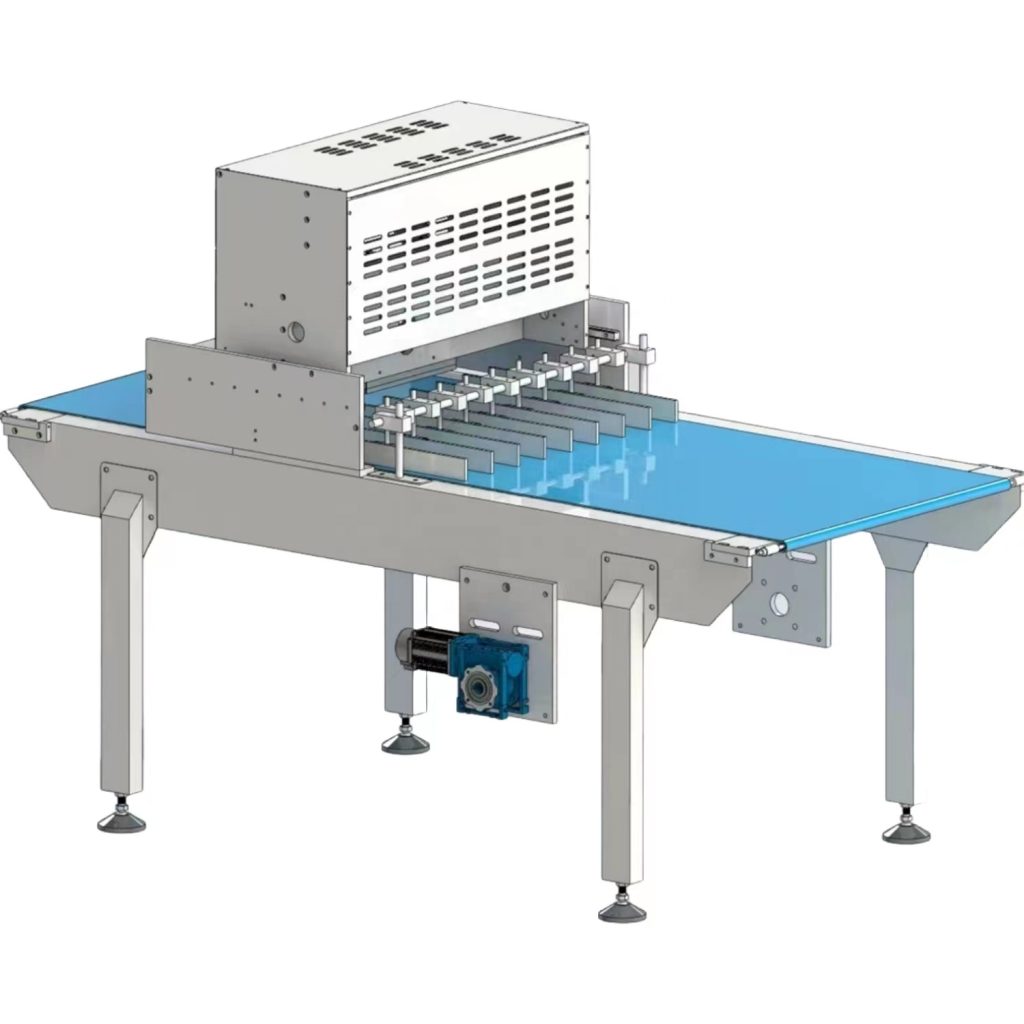

Large fully automatic assembly line machines: suitable for food processing factories

They can be seamlessly connected with bread production lines (such as cooling lines and packaging lines) to realize the full automation of “baking – cooling – cutting – packaging”. They support presetting cutting parameters through the PLC control system (such as automatically adjusting the thickness and speed for different batches of bread), with a cutting capacity of more than 500 loaves per hour, greatly reducing manual intervention. They are suitable for large-scale production of large baking enterprises.

From commercial bakeries and sandwich shops to large-scale food production facilities, these machines are indispensable for efficiently slicing toasted bread for sandwiches, burgers, and other culinary creations.

1. We have experience in food cutting machine more than 10 years.

2. We offer OEM custom service, produce and process products according to your drawings and requirement.

3. Our ultrasonic cutters have the following characteristics, they do not stick to the knife during operation; they do not deform the food, and the cut surface is very neat.

Model:Wanlisp4-300K1450L2000

Dimensions:2000*W900*H1400mm

Weight:Net Wt.210KGS, Gross Wt.310KGS

Voltage:220V

Rated power:50HZ-60HZ

Frequency:20000Hz

Cutting speed:60 cuts/minute( adjustable)

Number of blades:2(optional)

Blade materials:Titanium Alloy

Wanli Group offers innovative and customized bakery cutting solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your food production.

To reach our anytime via email, please fill out the form below with your request and a company representative will reply to you. To find your local WANLISONIC representative to connect directly click your region in the contact drop down menu.

Contact WANLISONIC For immediate assistance please contact us the corporate headquarters during business hours at 8:00 am – 24:00 pm.

NEWS

Wanli Ultrasonic Gummy Candy Cutting Machine

Wanli Ultrasonic Nougat Candy Cutter

WANLI Ultrasonic Swiss Roll Cutting Machine

Send Your Inquiry Today