Wanli Ultrasonic Cake Cutting Machine: Precision Cutting for Perfect Slices

If you’ve ever struggled to cut a soft, creamy cake without smearing the frosting or crushing the layers, you know the frustration. The Wanli Ultrasonic Cake Cutting Machine solves that problem with high-frequency precision — delivering perfect slices every single time. From small bakeries to high-volume dessert factories, this technology is a game-changer.

Understanding Ultrasonic Cake Cutting Technology

How Ultrasonic Vibrations Work

Ultrasonic cutting uses a titanium blade vibrating at around These micro-vibrations reduce friction, letting the blade glide through soft, sticky, or frozen products with minimal resistance.

Key Differences from Traditional Cutting Methods

Traditional knives drag and compress cakes.

Ultrasonic blades slice cleanly, avoiding deformation.

Sticky toppings don’t cling to the blade.

Overview of Wanli as a Brand

History and Expertise in Food Processing Machinery

Wanli has decades of experience designing specialized ultrasonic food cutting equipment, supplying to clients in more than 50 countries.

Innovation in Ultrasonic Food Cutting

Their R&D team focuses on energy efficiency, hygiene, and adaptability, ensuring their machines meet diverse production needs.

Core Features of Wanli Ultrasonic Cake Cutting Machine

Precision Cutting with Titanium Blades

Titanium alloy blades maintain sharpness and withstand constant ultrasonic vibrations.

Non-Stick Cutting for Delicate Desserts

Perfect for cheesecakes, mousse cakes, and pastries with sticky toppings.

Adjustable Cutting Modes and Patterns

Choose straight cuts, wedges, or grids — all programmable.

Hygienic and Food-Safe Design

Stainless steel body meets HACCP and FDA food contact standards.

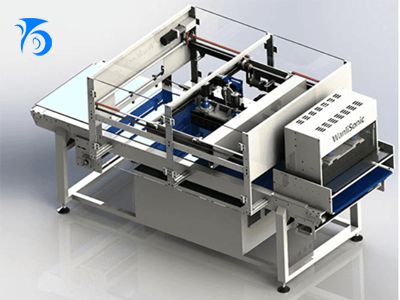

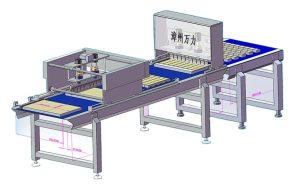

Integration with Automated Production Lines

Can be paired with conveyors for full-scale automation.

Benefits of Using Ultrasonic Cake Cutting Technology

No Product Deformation or Crumbs

Keeps layers, toppings, and decorations perfectly intact.

Increased Production Speed

Cuts faster than manual methods, improving output.

Less Waste and Better Yield

Clean slices mean minimal trimming and product loss.

Easy Maintenance and Cleaning

Non-stick blades reduce downtime between batches.

Cakes and Desserts Suitable for Ultrasonic Cutting

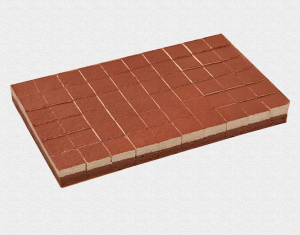

Cheesecakes and Mousse Cakes

Ideal for creamy textures that are hard to cut cleanly.

Sponge Layer Cakes

Maintains structural integrity of delicate layers.

Ice Cream Cakes and Frozen Desserts

Cuts without melting or cracking.

Brownies, Tarts, and Specialty Pastries

Ensures uniform pieces for packaging.

Production Efficiency Advantages

Reduced Downtime Between Batches

Minimal blade cleaning needed between cuts.

Consistent Results Across Large Volumes

Every slice matches the last in size and appearance.

Minimal Manual Labor Requirements

One operator can manage the process with ease.

Customization Options from Wanli

Blade Shapes and Sizes

Tailored to your products’ dimensions.

Wanli Standard machine with automatic removal of bottom baking paper function

Multi-Blade Systems

Cut multiple slices simultaneously.

Programmable Cutting Patterns

Custom designs and patterns available.

Safety and Ease of Operation

Safety Guards and Emergency Stops:Protects operators during high-speed cutting.

User-Friendly Touchscreen Controls:Simple interface for quick adjustments.

Operator Training and Support:Wanli provides full training packages.

Comparing Wanli with Other Ultrasonic Machines

Durability and Performance

Heavy-duty construction for long-term use.

Cost-Effectiveness and ROI

Faster payback due to increased output and reduced waste.

Applications in Commercial and Industrial Settings

Small Artisan Bakeries

Great for limited space while boosting quality.

Medium to Large-Scale Cake Manufacturers

Handles thousands of slices daily.

Frozen Dessert Production Lines,Consistent results even at sub-zero temperatures.

Customer Success Stories

Bakery Scaling Up Production:A boutique bakery tripled its output after installing Wanli’s system.

Factory Achieving Higher Efficiency

One factory cut labor costs by 40% while improving consistency.

Ordering Process and After-Sales Service

How to Get a Quote

Contact Wanli directly for tailored pricing.

Installation and Setup

On-site or remote installation options.

Technical Support and Spare Parts:Global service network for fast assistance.

The Wanli Ultrasonic Cake Cutting Machine delivers unmatched precision, speed, and consistency. Whether you’re a boutique bakery or a high-volume manufacturer, this technology ensures every slice is perfect — boosting efficiency, reducing waste, and keeping customers happy.

And that If your bakery or dessert production line needs speed, consistency, and hygiene, the Wanli Ultrasonic Cake Cutting Machine is an investment that pays for itself in efficiency and quality. By replacing manual cutting with ultrasonic precision, you’ll deliver perfect slices every time — with less waste and more output.