Insufficient traditional cutting

Although the traditional mechanical cutting method is relatively cheap, there are many limitations in cutting products. For example, when using traditional cutters to cut cakes, due to the softness of the cakes, problems such as deformation and breakage of the cakes are prone to occur during the cutting process, which destroys the beauty of the cakes and causes waste. Although the appearance of the cake cutting machine has greatly improved the cutting efficiency of the cake, the problem that the cutting edge of the cake is uneven and easy to break still exists. Moreover, automatic cake cutting only uses stainless steel cutting blades, and some cream cakes themselves have relatively high viscosity, so the blades often stick together, which will also affect the overall work efficiency. For example, foods such as bread and cheese similar to cakes also have similar problems.

Cutting principle

Ultrasonic cutting is the use of ultrasonic high-frequency vibration for product cutting, which is called a vibrating blade rather than a static blade in the traditional sense to a certain extent. High-frequency ultrasonic vibration can provide a friction-free cutting surface, which can not only keep the blade clean, but also reduce the number of production stoppages and improve the efficiency of product processing

Ultrasonic cutting system

Generator: It can convert AC voltage into high-frequency electrical energy, thereby providing the required energy for the transducer.

Transducer: A sealed electromechanical device that receives electrical energy from a power source and converts it into high frequency mechanical vibrations.

Horn: Located between the transducer and the cutting tool head, it amplifies or reduces the vibration amplitude (range of motion) of the tool head.

Tool head: Each tool head is customized for a specific application, and different tool heads are selected for cutting according to the application.

Integrated equipment: the ultrasonic cutter can be used alone or installed in an integrated equipment

The types of food that can be cut by the ultrasonic cake cutting machine mainly include: sandwich cake, layer cake, bread, Swiss roll, date cake, cream cake, mousse cake, donkey-hide gelatin, pizza, Shaqima, chocolate, cookies, cheese, all kinds candies and more.

What is ultrasonic cutting

The ultrasonic cake cutting machine uses the ultrasonic vibration of the cutting knife, which has small frictional resistance, the food will not be deformed due to extrusion, and it is not easy to stick to the blade, which makes up for the shortcomings of the existing cutting methods. This is especially effective for sticky food, frozen food, fragile food, such as cake, candy, donkey-hide gelatin, dried fruit, butcher shop, etc.

Why Use an ultrasonic cake cutting machine

01. High cutting efficiency

On the basis of ensuring precise cutting, it can preserve the integrity of the cutting object to the greatest extent: the incision is fine, the layers are clear, no chipping, and no sticking to the knife. The equipment consists of multiple sets of cutting knives, suitable for use in product lines.

02. Many types of cutting

Frozen products, fragile products, sticky foods, creamy products, etc. can be adapted. After cutting, the incision is delicate, smooth, non-deformed, and non-colored, which improves the appearance of the product.

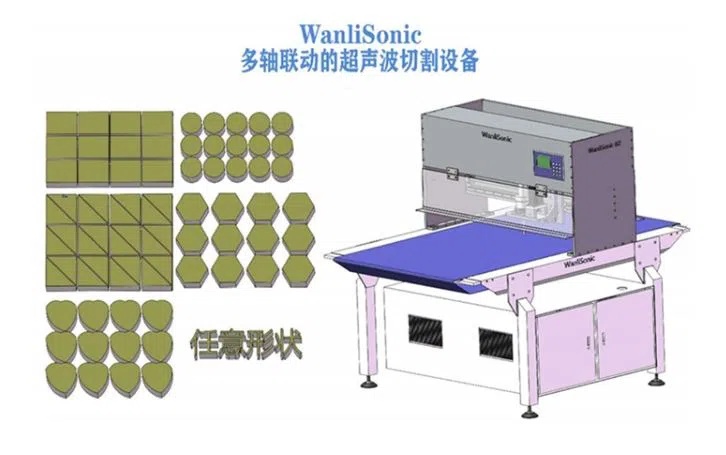

03. Rich cutting shapes

Can be cut: flakes, rectangles, triangles, equal circles

04. Can be customized according to requirements

Fully automated production line, can provide processing solutions according to customer needs

05. Clean and hygienic

Food hygiene is of paramount importance when it comes to food cutting. The process of implementing ultrasonic food cutting requires strict hygienic conditions to reduce the risk of food contamination. At the same time, due to the low-friction characteristics of the ultrasonic cutting knife, there is little adhesion when cutting food, which keeps the blade clean and reduces cleaning costs.

Related Products