As a key equipment in bread production, bakeries, and food processing scenarios, bread cutting machines have their core selling points centered around cutting efficiency, finished product quality, operational convenience, and applicable scenarios. zhangzhouwanli comprehensively optimized the pain points of traditional manual cutting.

1.Maximum Cutting Precision and Consistency, Ensuring Product Standardization

When cutting bread manually, it is easy to have inconsistent slice thickness and skewed edges due to uneven force and angle deviation, which affects the appearance and subsequent sales. However, bread cutting machines achieve “each slice is the same” through precise mechanical control:

Precise thickness control: Most models are equipped with digital knobs or touch screens, which can accurately set the slice thickness (usually ranging from 0.5mm to 50mm). From ultra-thin toast slices (suitable for sandwiches) to thick-cut baguette slices (suitable for dipping sauce), the error can be controlled within ±0.1mm, avoiding the “uneven thickness” of manual cutting.

Flat edges without damage: For breads of different textures such as soft bread (like chiffon cake, cream bread) and crispy bread (like baguette, European bread), the blades of the cutting machine are made of special materials (such as food-grade stainless steel, serrated knives). Combined with a uniform speed conveying device, it will not squeeze the bread body to cause collapse (soft bread) or crumbs (crispy bread) during cutting. The edges are smooth without serrations, improving the product’s appearance.

High consistency in batch cutting: In mass production of baking factories or chain stores, after being processed by the cutting machine, each slice of bread in the same batch has completely uniform size and shape, meeting the standardization requirements of chain brands, and avoiding quality fluctuations caused by fatigue and experience differences in manual operations.

2. High Efficiency and Labor Saving, Greatly Improving Production Efficiency

Manual bread cutting is time-consuming and labor-intensive, and a single person can cut at most 20-30 loaves per hour, which is difficult to meet the batch demand. However, bread cutting machines achieve efficiency leap through automated design:

High-speed continuous cutting: Small desktop models can cut 50-100 loaves per hour, and large assembly line models (equipped with conveyors) can reach more than 300 loaves per hour, which is 5-10 times more efficient than manual cutting. For example, during the morning peak hours in bakeries, it only takes 10 minutes to process 100 loaves of toast with a cutting machine, while it takes at least 1 hour manually.

Labor-saving operation, reducing labor costs: There is no need to hold the bread and press to cut manually. You only need to put the bread into the feed inlet, and the equipment will automatically complete the conveying, positioning, and cutting processes. A single person can operate multiple devices at the same time or take care of other processes (such as packaging), reducing labor input.

Adapting to large-sized bread: For long bread (such as 1-meter-long baguette), round bread (such as European round bread), and giant toast (commercial large size), manual cutting requires repeated angle adjustment. However, the width and height of the feed channel of the cutting machine can be adapted to different sizes (usually the maximum width is 30cm and the height is 20cm), and the entire cutting can be completed with one feed without segmental processing.

3. Adapting to Various Types of Bread, Solving the Difficulties of Cutting “Special Textures”

Different breads have great differences in texture due to different raw materials (whole wheat, cream, nuts, dried fruits) and processes (fermentation degree, baking hardness). Manual cutting is prone to problems such as “soft bread deformation, hard bread crumbs, and stuffed bread filling leakage”. However, professional bread cutting machines are perfectly adapted through targeted design:

Soft/fluffy bread: no collapse or deformation

For soft-textured breads such as chiffon bread and cloud bread, manual cutting will crush the bread body with a little force, resulting in the collapse of internal air holes. The cutting machine adopts the design of “light pressure conveying + thin blade cutting”. When the blade contacts the bread, it only exerts minimal pressure, and with uniform feeding, the bread body remains fluffy after cutting, and the internal air holes are intact.

Crispy/hard bread: no crumbs or debris

For crispy breads such as baguettes, pretzels, and whole wheat hard European bread, manual cutting is easy to produce a lot of crumbs (which not only wastes raw materials but also pollutes the operating table). The serrated blade of the cutting machine is specially polished, and the tooth pitch matches the hardness of the bread. During cutting, “serrated occlusion + quick cutting” reduces friction, and the amount of crumbs is more than 80% less than that of manual cutting. In addition, the blade speed can be adjusted (the speed can be reduced for ultra-hard bread to avoid the skin breaking due to high-speed impact).

Stuffed bread: no filling extrusion or damage

For stuffed breads with cream, jam, or nuts, manual cutting is easy to squeeze and cause filling overflow. The feeding device of the cutting machine has a “flexible positioning” function, which can gently fix both sides of the bread without squeezing the center. The blade accurately cuts the bread body while avoiding the area where the filling is concentrated. After cutting, the filling remains intact and the edges are clean.

4. Guaranteed Sanitation and Safety, Meeting Food-Grade Standards

Food processing has high requirements for sanitation. Bread cutting machines fully meet food safety standards in terms of materials and cleaning design:

Food-grade materials, non-toxic and harmless

The parts in contact with bread (blades, conveyor belts, feed chutes) are made of 304 stainless steel or food-grade silica gel, which are high-temperature resistant and corrosion-resistant. They will not breed bacteria due to long-term contact with bread crumbs and grease, and meet national food machinery safety standards (such as GB 4706.43).

Easy-to-clean design, reducing hygiene dead corners

The blades of most models can be quickly disassembled (without tools), the conveyor belt can be taken out separately for cleaning, and the corners of the feed chute are designed with arcs (no right-angle dead corners) to avoid residual bread crumbs. Some high-end models are also equipped with automatic cleaning functions (such as high-pressure water spray + ultraviolet disinfection). After cutting, the program can be started to clean the blades and contact surfaces, reducing the time for manual cleaning and the risk of cross-contamination.

Anti-pinch protection, safer operation

The equipment is equipped with infrared sensors or mechanical protection devices. When hands approach the feed inlet or blade area, it will automatically stop, avoiding the risk of being scratched by tools during manual cutting, which is especially suitable for scenarios where bakery employees operate frequently.

5. Flexibly Adapting to Scenarios, Suitable for Both Stores and Factories

Bread cutting machines are designed with various models according to different usage scenarios, meeting the full-scene needs from individual bakeries to large food factories:

Small desktop machines: suitable for stores and small workshops

They are small in size (usually 50cm in length × 40cm in width × 30cm in height), can be directly placed on the operating table, do not need fixed installation, and can be used by plugging in the power. They are suitable for scenarios with a daily cutting volume of less than 50 loaves (such as community bakeries and coffee shops). They are affordable (several thousand yuan), easy to carry and maintain.

Medium-sized semi-automatic machines: suitable for chain stores and central kitchens

Equipped with a conveyor belt and a speed-adjustable motor, they can continuously feed and cut, support batch processing, and can be compatible with various bread shapes (round, long, square). Some models have a “counting function” that can count the number of cuts, facilitating inventory management. They are suitable for scenarios with a daily cutting volume of 100-300 loaves.

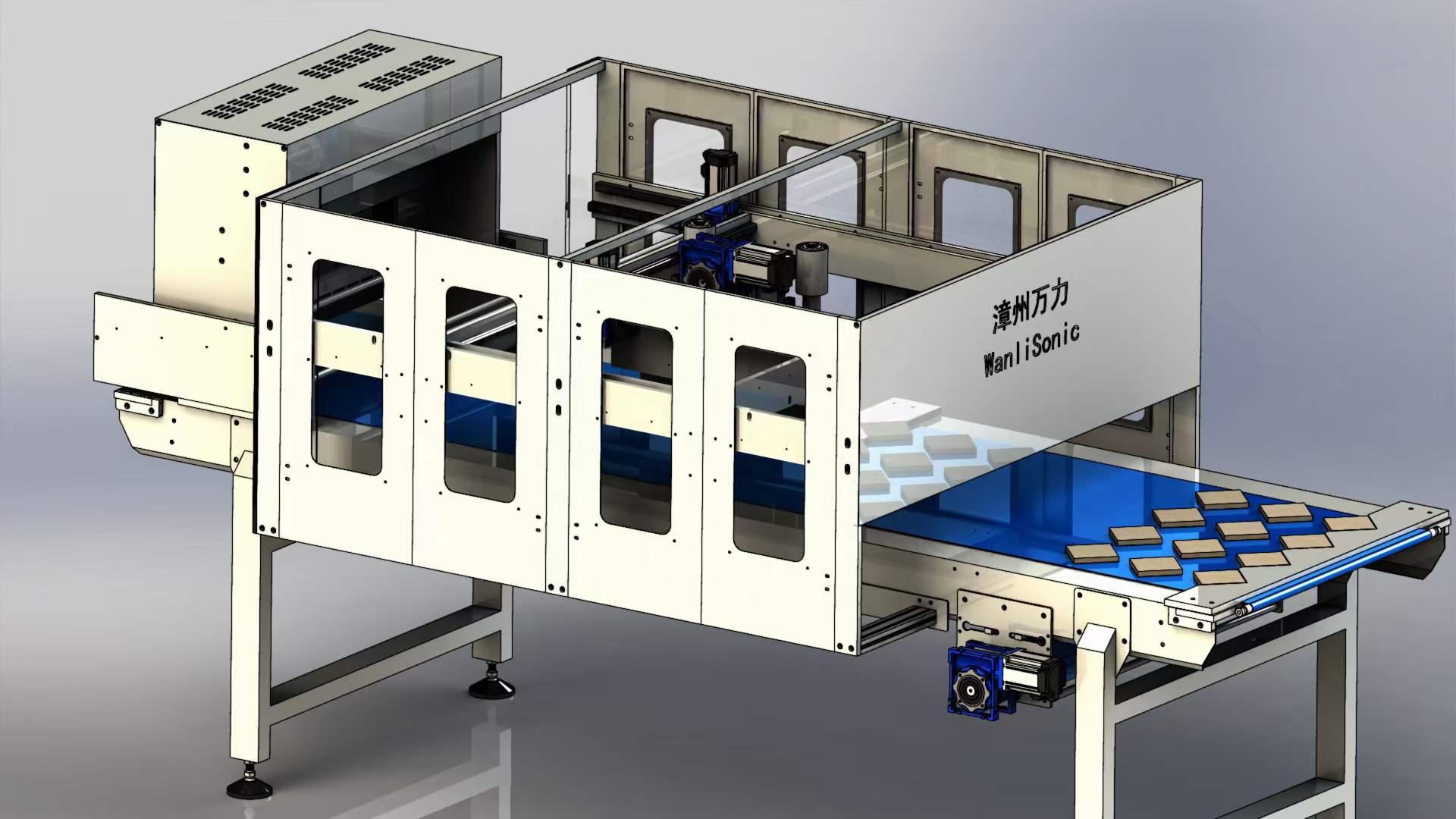

Large fully automatic assembly line machines: suitable for food processing factories

They can be seamlessly connected with bread production lines (such as cooling lines and packaging lines) to realize the full automation of “baking – cooling – cutting – packaging”. They support presetting cutting parameters through the PLC control system (such as automatically adjusting the thickness and speed for different batches of bread), with a cutting capacity of more than 500 loaves per hour, greatly reducing manual intervention. They are suitable for large-scale production of large baking enterprises.

6. Reducing Raw Material Waste and Improving Cost Control Capability

During manual bread cutting, due to irregular edges and many crumbs, it is often necessary to cut off the “unqualified parts”, resulting in raw material waste (usually 5%-10% waste rate). However, bread cutting machines directly reduce waste through precise cutting and low-loss design:

Few crumbs, high raw material utilization rate: For crispy bread, the crumb amount can be controlled within 1%; for soft bread, there are almost no crumbs. The part that was originally wasted due to “scraps” can be fully converted into finished products. Based on processing 100kg of bread per day, the annual raw material cost can be saved by tens of thousands of yuan.

Reducing “secondary processing” loss: Unqualified products from manual cutting (such as skewed slices and damaged slices) need to be reprocessed (such as making bread crumbs), while the qualified rate of finished products from the cutting machine is over 99%, reducing the time and labor cost of secondary processing.

In conclusion, the core selling points of bread cutting machines can be summarized as: centered on “precision, efficiency, low consumption, and safety”, they solve the pain points of manual cutting such as “non-standardization, low efficiency, high loss, and difficult sanitation guarantee”. At the same time, they adapt to all scenarios through various models, and are key equipment for the baking industry to achieve standardized production, reduce costs, and increase efficiency.