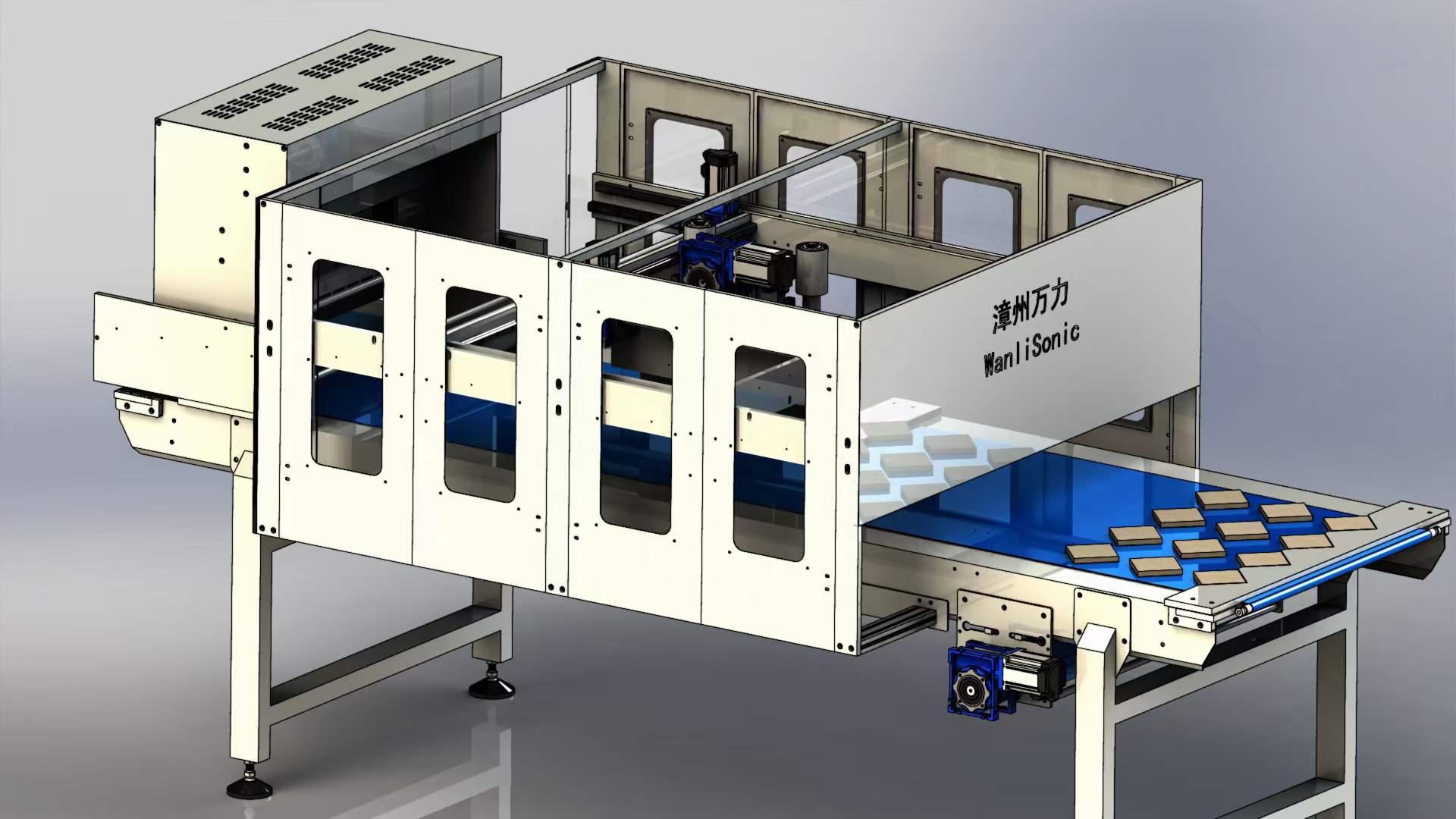

Introduction to the Wanli Ultrasonic Candy Cutting Machine

If you’re in the candy business, you know that precision is key to producing high-quality products. That’s where the Wanli Ultrasonic Candy Cutting Machine comes in. This cutting-edge technology is revolutionizing how candy manufacturers cut and shape their products. Unlike traditional cutting methods, which can be rough and imprecise, the Wanli Ultrasonic machine uses ultrasonic waves to achieve clean, accurate cuts. But what makes this machine truly stand out in the market? Let’s dive in!

The Technology Behind the Wanli Ultrasonic Cutting Machine

What is Ultrasonic Cutting?

Ultrasonic cutting is a process that uses high-frequency sound waves to cut through materials. It sounds pretty sci-fi, right? But this technology is well-established and incredibly effective for cutting delicate products like candy. The ultrasonic machine generates high-frequency vibrations that are transferred to a blade. When the blade touches the candy, the vibrations allow it to cut through smoothly and cleanly, minimizing the pressure on the candy and reducing the risk of deformation.

How Does Ultrasonic Technology Work for Candy Cutting?

In the case of the Wanli Ultrasonic Candy Cutting Machine, the blade operates at an ultrasonic frequency (usually between 50-60kHz). These vibrations break down the surface tension of the candy, allowing it to cut with less force. This results in a cleaner cut, better product quality, and less waste. Plus, the machine works with both soft and hard candies—so you’re covered no matter what type of product you’re making

Key Features of the Wanli Ultrasonic Candy Cutting Machine

Speed and Efficiency in Cutting

When it comes to production lines, time is money. The Wanli Ultrasonic Candy Cutting Machine doesn’t disappoint. It can cut through large volumes of candy in a fraction of the time compared to traditional methods. This efficiency not only speeds up production but also helps reduce labor costs, as fewer people are needed to monitor and operate the machine.

Precision and Accuracy

One of the standout features of this machine is its precision. Whether you’re cutting intricate candy shapes or evenly sized candy pieces, the ultrasonic technology ensures that each cut is consistent. It’s a game-changer for manufacturers aiming for uniformity and perfection in every batch.

Minimal Wastage

With traditional cutting methods, there’s always a chance that some candy gets wasted due to uneven cuts or pressure that deforms the product. With the Wanli Ultrasonic Cutting Machine, there’s far less wastage. The clean, smooth cuts mean that more of the candy goes into the final product, improving both yield and profitability.

Advantages of Ultrasonic Technology in Candy Cutting Clean Cuts Without Deforming the Candy

One of the primary benefits of ultrasonic cutting is its ability to make clean, precise cuts without deforming or compressing the candy. This is especially important for delicate candies like chocolates and pralines, which can easily lose their shape or texture with traditional cutting methods.

Suitable for Hard and Sticky Candies

Ultrasonic cutting is versatile. It can handle a variety of candy types, including hard candies, chewy gummies, and sticky chocolate products. The vibrations from the ultrasonic waves break through the tough surface of hard candies without crushing or damaging the internal texture. Similarly, sticky candies are cut with ease, preventing them from sticking to the blade.

Consistency and Uniformity in Production

If you’re running a large-scale production line, consistency is vital. The Wanli Ultrasonic Candy Cutting Machine ensures that every piece of candy is cut with the same precision. This reduces errors and ensures that all your products are uniform in size and shape, which is crucial for packaging and presentation.

Materials Compatible with the Wanli Ultrasonic Candy Cutting Machine

Hard Candies

Hard candies are known for their tough exterior, making them difficult to cut with traditional methods. But with the Wanli Ultrasonic Cutting Machine, you can easily slice through these candies without worrying about cracking or breaking the product.

Chocolates and Pralines

Chocolate and praline manufacturers often struggle with the challenge of cutting through smooth, delicate products without damaging the texture. The ultrasonic cutting machine allows manufacturers to cut through chocolate with minimal pressure, preserving the glossy finish and smooth texture.

Gummy Candies and Jelly Products

Sticky and chewy products, like gummies or jelly-based candies, are no match for traditional cutting methods. They tend to get stuck on blades or lose their shape. The Wanli Ultrasonic Candy Cutting Machine solves this problem by cutting with vibrations that prevent the candy from sticking, while maintaining its shape and consistency.

Benefits for Manufacturers Increased Production Capacity

One of the most immediate benefits manufacturers see with the Wanli Ultrasonic Candy Cutting Machine is an increase in production capacity. Since the machine works quickly and efficiently, candy makers can process more product in less time. Whether you’re a small business or a large manufacturer, this machine will boost your overall output.

Reduced Labor Costs

Automation is a significant factor in reducing labor costs. With the Wanli Ultrasonic Cutting Machine, you need fewer people to operate the production line. The machine’s efficiency means that your employees can focus on other tasks while the ultrasonic cutter handles the bulk of the work.

The Role of Automation in Candy Production

How Automation Enhances Efficiency|

The Wanli Ultrasonic Candy Cutting Machine is just one example of how automation is improving candy production lines worldwide. By automating the cutting process, manufacturers can maintain consistent quality, reduce human error, and speed up production. In turn, this helps increase profitability and allows manufacturers to focus on innovation and growth.

Integration with Other Production Lines

The Wanli Ultrasonic Candy Cutting Machine integrates seamlessly with other parts of the candy production process. Whether you’re mixing, molding, or packaging your candies, this machine can fit into your existing production lines without causing significant disruptions.

Cost-Efficiency of the Wanli Ultrasonic Cutting Machine.

Initial Investment vs. Long-Term Savings,While the Wanli Ultrasonic Candy Cutting Machine may require a significant initial investment, the long-term savings it provides far outweigh the cost. The machine’s speed, precision, and minimal maintenance requirements mean that candy manufacturers will see a solid return on investment in a short period.

Energy Consumption and Maintenance Costs

Another advantage of ultrasonic cutting technology is its low energy consumption. It uses less energy compared to other high-speed cutting methods, which makes it more environmentally friendly and cost-effective. Additionally, the maintenance requirements are minimal, which further reduces operating costs over time.

Maintenance and Care of the Wanli Ultrasonic Candy Cutting Machine

Routine Cleaning and Maintenance Steps

To keep the Wanli Ultrasonic Candy Cutting Machine running smoothly, regular cleaning is essential. This includes wiping down the cutting area, checking the ultrasonic tips for wear and tear, and ensuring that the blades remain sharp. Proper care helps extend the life of the machine and maintains its cutting efficiency.

Custom Blade Options

To meet different production needs, the Wanli Ultrasonic Candy Cutting Machine offers a variety of customizable blades. Whether you need to cut small pieces, large chunks, or intricate designs, the machine can be tailored to your specific requirements.

Adjustable Cutting Speeds and Sizes

For manufacturers looking to optimize their processes, the machine’s adjustable cutting speeds and sizes provide flexibility. Whether you’re running a high-volume production line or cutting specialty candies, this machine can adapt to meet your needs.

How the Wanli Ultrasonic Candy Cutting Machine Stands Out in the Market

Comparison with Traditional Candy Cutting Machines

Compared to traditional candy cutting methods, the Wanli Ultrasonic Cutting Machine offers significant improvements in terms of speed, precision, and efficiency. While traditional methods rely on mechanical pressure, ultrasonic cutting uses vibrations to create cleaner, more accurate cuts, making it ideal for delicate or hard-to-cut candies.

Unique Selling Points of the Wanli Machine

What sets the Wanli Ultrasonic Candy Cutting Machine apart is its versatility and high level of customization. From its low maintenance requirements to its ability to handle various types of candy, it’s a top choice for manufacturers looking for cutting