|

Key Selling Points of Ultrasonic Cookie Cutting Equipment

In the field of baking equipment, ultrasonic cookie cutters have become an ideal choice for many baking enterprises to improve production efficiency and product quality due to their unique technical advantages.

1. Precise Cutting: Ensuring Perfect Cookie Shape

This is a significant advantage of ultrasonic cookie cutters.

Traditional cutting methods are prone to causing cookies to deform or break due to excessive pressure.

However, ultrasonic cookie cutters utilize the principle of high-frequency ultrasonic vibration. When cutting, the contact area with the cookies extremely small, and the cutting action can be completed in an instant, effectively avoiding extrusion deformation and crumb generation on the cookie edges.

Whether it is complex-shaped cartoon cookies or uniformly thick crispy cookies, they can maintain smooth edges and regular shapes, greatly improving the appearance quality and market competitiveness of the products.

2. Wide Adaptability: Meeting Diverse Production Needs

This is also an unignorable highlight of ultrasonic cookie cutters.

Different types of cookie dough have significant differences in characteristics. Some are soft in texture, while others contain high levels of oil and sugar, which traditional cutters often struggle to handle.

By adjusting the vibration frequency and cutting force, ultrasonic cookie cutters can easily meet the cutting needs of various types such as shortbread cookies, tough cookies, and sandwich cookies.

They can even handle complex dough with granular ingredients like nuts and dried fruits, providing strong support for baking enterprises in diversified product production.

3. High Efficiency and Stability: Enhancing Overall Production Efficiency

This is the key for ultrasonic cookie cutters to create value for enterprises.

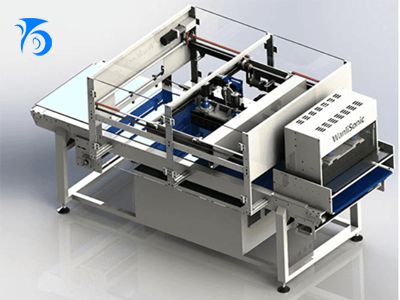

The equipment adopts an automatic control system, which can seamlessly connect with the production line to realize continuous cutting operations, significantly reducing efficiency fluctuations caused by manual intervention.

At the same time, the ultrasonic cutting technology has strong stability, and it is not easy to have a decline in cutting accuracy even during long-term operation, effectively reducing the rejection rate.

In addition, its cutting speed can be flexibly adjusted according to the rhythm of the production line, and the maximum speed can meet the mass production needs of large baking factories, helping enterprises increase output within a limited time.

4. Easy Maintenance: Reducing Equipment Operating Costs

This aspect adds points to ultrasonic cookie cutters.

The core cutting components of the equipment are made of high-strength wear-resistant materials, which have a long service life and reduce the trouble and cost of frequent replacement of accessories.

Moreover, the equipment has a reasonable structural design, making cleaning and maintenance convenient. Operators only need to carry out daily maintenance in accordance with the specifications to ensure the good operating condition of the equipment.

Compared with the problems such as blade wear and material jamming that are prone to occur in traditional cutters, ultrasonic cookie cutters have a lower failure rate, which can save enterprises a lot of maintenance time and costs.

5.Key Selling Points: Beyond Precision and Efficiency

Adaptability: Mastery Over All Dough Types

Whether working with soft, high-moisture dough (e.g., sugar cookies), sticky dough (e.g., gingerbread), or dough loaded with inclusions (e.g., oatmeal raisin), ultrasonic cutters handle them all. The vibration breaks through tough particles (like nuts) without tearing the dough, while the “non-stick” effect prevents soft dough from clinging to the blade—eliminating the need for flour dusting (which can alter dough texture) or frequent blade cleaning

Waste Reduction: Maximize Raw Material Use

Ragged edges, misshapen cuts, and dough compression from traditional tools lead to significant 原料 waste. Ultrasonic cutters produce clean, uniform edges, so nearly every cut piece is usable. Over time, this reduction in waste lowers raw material costs—a major win for large-scale operations.

Easy Maintenance: Lower Long-Term Costs

Traditional cutters require frequent sharpening, cleaning, and replacement due to dough buildup and wear. Ultrasonic blades, with their low-friction design, stay cleaner longer and resist dulling. Many models feature detachable, dishwasher-safe components, simplifying upkeep and reducing labor costs associated with maintenance.