Characteristics and Usage of Cheese Cutting Machine

I. Core Characteristics

- Precise cutting, ensuring intact shape

Cheese has various textures, ranging from soft Brie to hard CheddarA Guide to Cheese Cutters: Characteristics and Usage with different properties. The cheese cutting machine is equipped with a high-precision cutting system. Through adjustable-speed blades or ultrasonic vibration technology, it can adjust the cutting force according to the hardness of the cheese, avoiding deformation of soft cheese and fragmentation of hard cheese. It ensures a flat cutting surface and retains the original shape of the cheese, which is especially suitable for catering scenarios with high requirements on appearance.

- Adapting to various specifications, meeting flexible needs

The equipment supports multi-gear size adjustment, which can cut into various forms such as thin slices, cubes, and strips, with thickness ranging from a few millimeters to several centimeters. Whether it is ultra-thin cheese slices for pizza or cheese cubes for cold platters, it can be quickly achieved through parameter setting, adapting to the diversified needs of different scenarios such as families, restaurants, and food processing factories.

- Efficient and labor-saving, improving operation efficiency

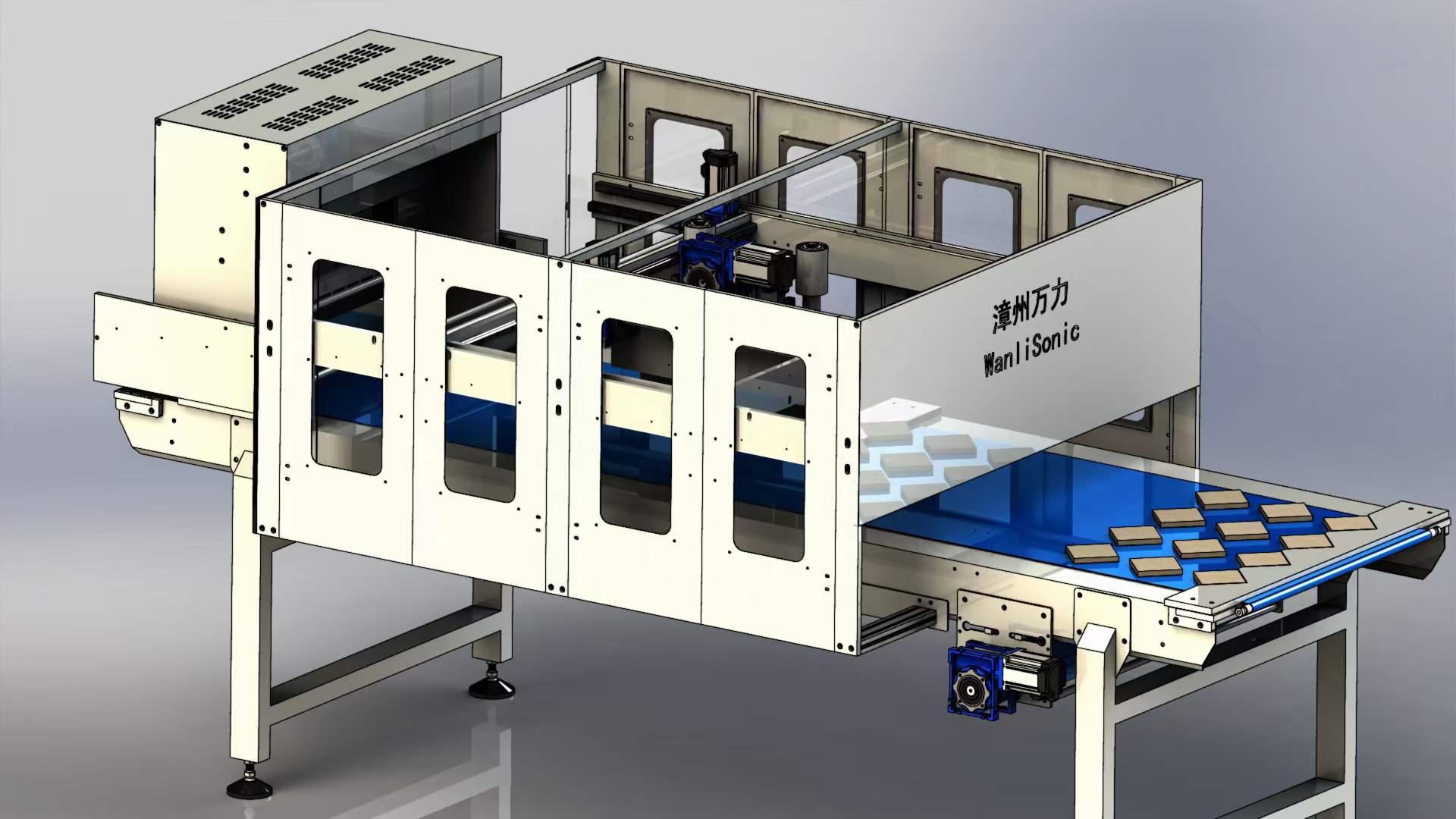

Compared with manual cutting, the cheese cutting machine adopts electric drive or automatic conveying device, which greatly reduces labor costs. Commercial models can handle dozens of kilograms of cheese per hour, far exceeding the speed of manual cutting; small household models adopt ergonomic design to make operation more labor-saving, especially suitable for scenarios with frequent use.

- Safe and hygienic, meeting food standards

The parts of the machine body that come into contact with cheese are mostly made of food-grade stainless steel, which is corrosion-resistant and easy to clean, avoiding bacterial growth. Some models are equipped with detachable blades and protective devices, which not only facilitate daily cleaning and maintenance but also prevent the risk of scratches during operation, complying with the hygiene and safety standards of food processing.

- Strong durability, adapting to long-term use

The blades are made of high-hardness alloy material, which has undergone special quenching treatment, significantly improving the wear resistance against hard cheese and reducing the frequency of replacement. The machine body has a stable structure, which can withstand long-term high-frequency use, reduce the equipment loss rate, and prolong the service life.

II. Usage Methods

- Preliminary preparation

Adjust the equipment parameters according to the type of cheese: select lower cutting speed and pressure for soft cheese, and appropriately increase them for hard cheese; set the required cutting size, such as thickness and length. At the same time, clean the contact surface of the equipment to ensure no impurities remain.

- Placement and fixation

Place the cheese steadily on the conveying table or cutting platform. For irregularly shaped cheese, it can be fixed with a positioning baffle to prevent size deviation caused by sliding during cutting.

- Start cutting

Household models are mostly started by manual pressing, while commercial models can be started through a foot switch or automatic induction device. Keep the cheese in a stable position during cutting to avoid moving halfway. For automatic models, just put the cheese into the feed inlet, and the equipment will automatically complete the conveying, cutting, and discharging processes.

- Post-processing

After cutting, turn off the power of the equipment and take out the cut cheese in time. Remove the blades and contact parts, clean them with water or food-grade detergent, dry them, and reinstall them for next use.

With the above characteristics and usage methods, the cheese cutting machine can not only solve the problems of low efficiency and poor shape in manual cutting but also meet the precise needs of different scenarios, becoming a practical tool for processing cheese in food processing.