With the Altrasonic ultrasonic cutting machine, you can cut a wide range of products in the food industry. Machines can improve product quality, cut faster and be more efficient.

With the Altrasonic ultrasonic cutting machine, you can cut a wide range of products in the food industry. Machines can improve product quality, cut faster and be more efficient. You will get less waste, which will bring you more profit.

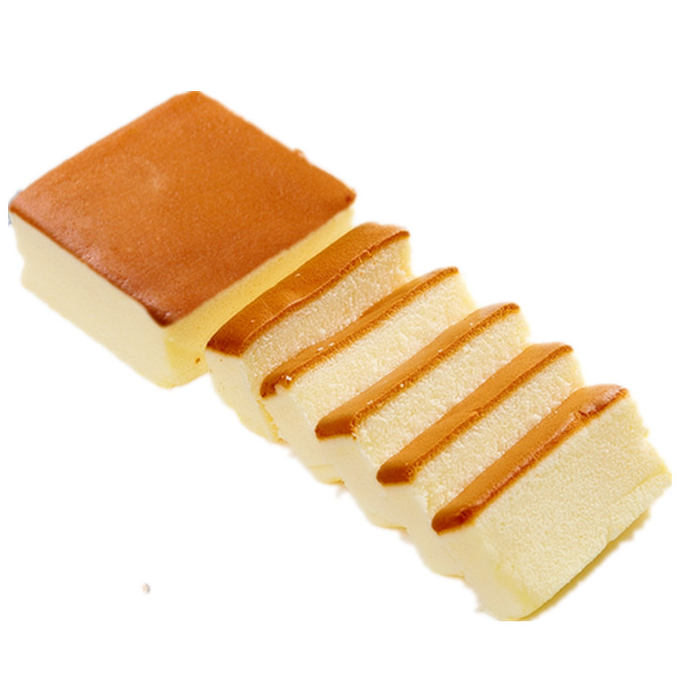

Cutting cake processing is very important . Currently widely used cake cutter ordinary stainless steel knife

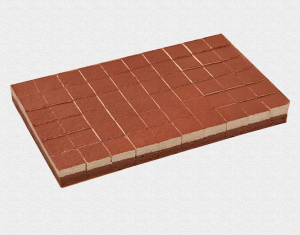

stainless steel knife is the use of a sharp cutting edge, acting on the cake at the cutting force is large, easy to damage the shape of the cake, a higher rejection rate, resulting in the production increase in cost. In addition, multi-layered cake points, is likely to cause mixing cutting, greatly reducing the aesthetics. To solve the ordinary stainless steel cutter when cutting a cake problems ,Wanlisonic developed ultrasonic food cutting equipment to solve the stick blade and perfect color mixing problem. Ultrasonic food cutting expe-riment is the role of ultrasound energy to the knife, high-frequency vibration in the ultrasonic knife between the cake and the establishment of a little surface friction, so there will be no sticky knife and mixing problems.The ultrasonic food cutting equipment for automated production lines, without having to stop the knife clean,not only increase productivity, reduce scrap rates cake, but also greatly reduces the cost of production.

1.Bakery industry

2.Bread industry

3.cake industry

1. Ultrasonic processing is an efficient way to cut, slice, divert, align or transfer a variety of products.

It involves a vibrating blade producing a nearly frictionless surface with the influence of ultrasonic which does not deform products and to which they do not stick. The vibrating frictionless blade cuts or slits products cleanly such as nuts, raisins, dried fruit or chocolate morsels without displacement or plowing.

2.Ultrasonic vibration reduces friction resistance between the blade and mterial, and it makes the blade cut smoothly without deformation.The cutting blade is made of titanium (or the material according to your requirement ). It is completely inert and enduring material.

3.The use of ultrasonic cutting , incision aesthetic integrity, trimming neatly smooth, without Burr, to leave the border areas, not black, not burned, not the hardware products to feel very good shear results.

| Item No. | WANLISP |

| Frequency | 50Hz |

| Power | 2000W |

| Length of Blade | 125/255/305mm |

| Generator | Digital, auto -tuning |

| Machine Weight | 15-18kg |

| Input | AC110-240V, 50/60Hz |

| Cable length | 3M or customized |

Wanli Group offers innovative and customized bakery cutting solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your food production.

To reach our anytime via email, please fill out the form below with your request and a company representative will reply to you. To find your local WANLISONIC representative to connect directly click your region in the contact drop down menu.

Contact WANLISONIC For immediate assistance please contact us the corporate headquarters during business hours at 8:00 am – 24:00 pm.

NEWS

Wanli Ultrasonic Layer Cake Cutting Machine

WANLI Ultrasonic Soft Cake Cutting Machine

Send Your Inquiry Today