Wanlisonic Ultrasonic Cake Cutting Machine: The Future of Precision Baking

Cutting a cake sounds simple—until you’re serving thousands of portions a day. From cheesecakes to mousse cakes, bakers know the struggle: sticky blades, uneven slices, and wasted product. That’s where the Wanlisonic ultrasonic cake cutting machine comes in. With precision technology, it transforms the art of cake slicing into a science.

What is Ultrasonic Cutting Technology?

Ultrasonic cutting uses high-frequency vibrations (usually 20–40 kHz) to power blades that slice through food without sticking. The vibrations create microscopic air pockets that act like a cushion, reducing friction.

Unlike traditional knives that drag and tear, ultrasonic blades glide effortlessly—leaving behind clean, sharp cuts.

Why Cakes Need Ultrasonic Cutting

Cakes are tricky. They’re soft, sticky, and full of delicate layers. Traditional knives often:

Smear frosting.

Crush sponge layers.

Stick to creamy fillings.

Ultrasonic cutting solves these issues, giving bakers neat, picture-perfect slices every time.

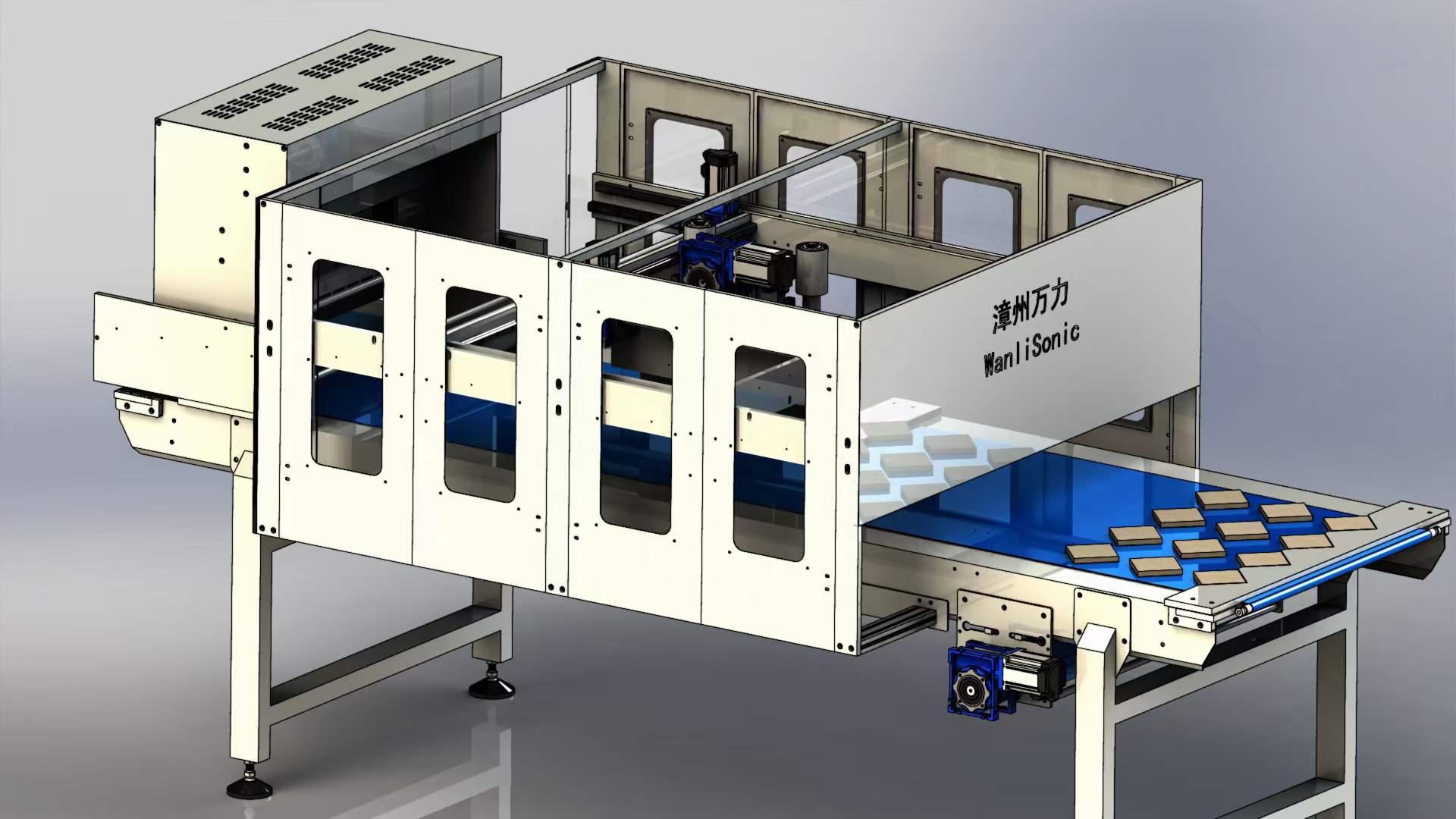

About Wanlisonic

Wanlisonic specializes in ultrasonic cutting machines for the food industry. Known for their durability, precision, and advanced automation, their machines are trusted worldwide by bakeries and confectionery producers.

Key Features of Wanlisonic Ultrasonic Cake Cutting Machine

Non-stick blades: No residue buildup, even on sticky cheesecakes.

Programmable slicing: Choose patterns, from straight cuts to intricate designs.

Adjustable settings: Control slice thickness and portion sizes.

Versatility: Handles frozen, chilled, or freshly baked cakes.

Durability: Built for continuous, industrial-scale use.

How It Works

How It Works

Place the cake on the conveyor or cutting platform.

The ultrasonic blade vibrates at high frequency.

The machine applies minimal pressure, slicing cleanly through.

Finished pieces are ready for packaging or serving.

The system integrates with bakery lines, making it ideal for high-volume operations.

Applications in Baking and Confectionery

Wanlisonic machines cut through:

Cheesecakes – no more crumbling edges.

Mousse cakes – delicate layers remain intact.

Ice cream cakes – handles frozen products with ease.

Pastries and brownies – consistent slices for packaging.

Advantages for Bakeries and Food Producers

Speed: Cut hundreds of portions in minutes.

Consistency: Identical slices every time.

Less waste: Precise cuts mean maximum yield.

Hygiene: Reduced manual handling improves food safety.

Customization Options

Wanlisonic understands that not all cakes are alike. That’s why their machines allow:

Different blade lengths.

Adjustable slice thickness.

Custom cutting patterns (triangular, square, or wedge).

Hygiene and Safety Standards

Made from food-grade stainless steel, the machines are easy to clean and maintain. They comply with global food safety certifications, ensuring reliability for bakeries of all sizes.

Energy Efficiency and Sustainability

Wanlisonic machines are designed to optimize energy use, helping bakeries lower operational costs. Less waste also means a greener production line

Ultrasonic Cutting vs. Traditional Cutting

| Feature | Traditional Knife | Wanlisonic Ultrasonic Cutter |

| Clean cuts | Often messy | Perfectly smooth |

| Blade sticking | Common issue | Non-stick vibration |

| Speed | Slower | Much faster |

| Waste | Higher | Minimal |

| Maintenance | Frequent sharpening | Longer blade life |

Who Uses Wanlisonic Machines?

Large-scale bakeries producing thousands of cakes daily.

Mid-sized cake shops looking to improve efficiency.

Frozen dessert companies cutting cheesecakes and ice cream cakes.

Return on Investment (ROI)

Yes, the machine is an investment. But here’s the sweet part:

Reduced labor costs.

Lower waste levels.

Faster production cycles.

Many bakeries report ROI within 12–18 months.

Customer Success Stories

A bakery in Europe reported a 40% production increase after installing a Wanlisonic machine. Another confectionery brand in Asia cut labor needs in half while improving product quality.

Future of Ultrasonic Cake Cutting

The future looks bright. Expect:

Smarter, AI-driven cutting systems.

More compact versions for small bakeries.

Integration with robotic arms for full automation.

Wanlisonic is already investing in these innovations, staying ahead of the curve.

The Wanlisonic ultrasonic cake cutting machine is more than just a cutter—it’s a bakery revolution. It delivers speed, precision, hygiene, and efficiency, helping bakers meet rising demands without compromising quality.

If you’re serious about scaling your cake business, this machine could be your secret ingredient to success.