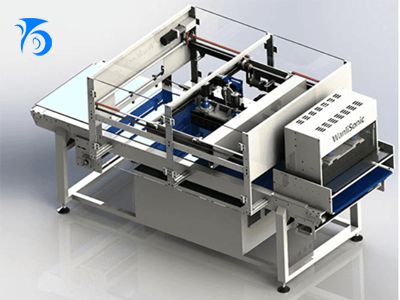

Wanli Ultrasonic Cheese Crushing and Cutting Machine

Cheese is one of the most loved foods worldwide, but behind every perfectly sliced block or shredded packet lies advanced processing technology. Cutting cheese might sound simple, but in the food industry, precision, hygiene, and efficiency matter more than ever. That’s where the Wanli Ultrasonic Cheese Crushing and Cutting Machine steps in—transforming how cheese is processed for consumers and businesses alike.

What is the Wanli Ultrasonic Cheese Crushing and Cutting Machine?

The Wanli machine is a specialized food-processing system designed to cut, crush, and portion cheese with unmatched accuracy. Unlike traditional knives or blades, this equipment uses ultrasonic vibrations to slice through cheese effortlessly, leaving behind smooth, clean edges. It’s widely used in both large-scale dairy production lines and smaller specialty cheese manufacturers.

How Ultrasonic Technology Works in Cheese Cutting

So, what’s the secret? Ultrasonic cutting technology relies on high-frequency vibrations, usually around 20–40 kHz. These vibrations reduce friction and resistance, allowing the blade to glide through even the stickiest cheese varieties without squashing or deforming them. Imagine trying to cut soft mozzarella with a dull knife—it sticks, crumbles, and makes a mess. With ultrasonic cutting, every slice comes out perfect.

Key Features of the Wanli Ultrasonic Cheese Cutter

High-frequency cutting power – Smooth, precise slices regardless of cheese type.

Hygienic design – Built with stainless steel for easy cleaning and sanitation.

Consistent results – Uniform cuts for better portion control and packaging.

Safety-first engineering – Smart sensors and protective designs keep operators safe.

Adaptability – Works with block cheese, soft cheese, shredded cheese, and more.

Benefits of Using Ultrasonic Cheese Cutting Machines

Perfect portion control – Each slice is identical in size, making packaging easier.

Reduced waste – No more broken or deformed cheese pieces.

Shelf appeal – Neat, uniform cuts make cheese look fresher and more attractive.

Lower operational costs – Less labor and less downtime due to reduced cleaning needs.

Crushing vs. Cutting: Dual Functionality Explained

This isn’t just a slicer—it’s also a crusher. The dual functionality makes it stand out in the industry.

Crushing mode – Ideal for preparing shredded cheese or breaking down bulk blocks for further processing.

Cutting mode – Designed for precise slicing of cheese blocks, rounds, or specialty products.

Applications in the Dairy Industry

The Wanli Ultrasonic Cheese Crushing and Cutting Machine is versatile enough to handle:

Block cheese cutting for retail packaging.

Soft cheese like brie or mozzarella, which normally sticks to blades.

Shredded cheese production, perfect for pizza chains and ready-meal companies.

Specialty cheeses requiring artisan-quality cuts.

Why Choose Wanli Over Competitors?

Wanli has built a reputation for innovation and reliability in ultrasonic food processing. Unlike generic machines, Wanli designs its cutters to adapt to different cheese textures, ensuring maximum efficiency. With global recognition and trust, many food manufacturers consider Wanli a top-tier choice.

Case Studies: Real-World Success Storie

Cheese factory in Europe – Increased production by 40% after switching from manual cutting

Packaging company in Asia – Reduced waste by 25% while improving shelf presentation.

Integration into Production Lines

Whether you need a standalone cutting station or a fully automated solution, Wanli machines integrate seamlessly into existing production lines. They’re designed to sync with conveyors, packaging systems, and automated weighing machines.

Energy Efficiency and Cost Savings

Despite their power, Wanli ultrasonic machines are energy-efficient, using less electricity than traditional industrial cutters. They also reduce manpower requirements, lowering labor costs significantly.

Cleaning and Maintenance

Made with stainless steel and modular components, these machines are designed for easy disassembly. This not only makes cleaning faster but also ensures compliance with strict food safety standards.

Future of Ultrasonic Cheese Cutting

Looking ahead, we can expect innovations like AI-controlled slicing precision, real-time monitoring, and eco-friendly designs. As sustainability becomes a priority, machines like Wanli’s will continue shaping the future of dairy processing.

Buying Guide: How to Choose the Right Model

When selecting the right Wanli cheese cutting machine, consider:

Cheese type (hard, soft, semi-soft),Production volume,Automation requirements,Customization options

Wanli offers flexible models to fit both small-scale businesses and large industrial plants.

The Wanli Ultrasonic Cheese Crushing and Cutting Machine is not just a piece of equipment—it’s a game-changer for the dairy industry. By combining speed, hygiene, and precision, it ensures manufacturers can deliver high-quality cheese products efficiently and consistently. If you’re in the dairy business, investing in this technology could be the smartest move you make.