The production line is composed of core parts such as automatic coating system, conveyor belt, teflon pressure roller, freezing tunnel, rolling cutter, high-speed chopper and hoist in sequence according to the production process. All links cooperate closely to realize the fully automated processing of cheese from slurry to final product, and accurately and efficiently send the finished product to the post-packaging line, which greatly improves the production efficiency and product quality stability

This cheese production line is a highly automated and integrated professional production equipment. The whole line is meticulously made of 304 stainless steel, which not only has excellent corrosion resistance, can resist various acids, alkalis and moisture that may be encountered in the production process, but also meets the hygiene standards of food production, ensuring that the cheese is not contaminated during production. The production line is equipped with automatic cleaning and automatic drying functions. Through the preset cleaning program, it can comprehensively clean key components such as the conveyor belt, pressure roller and cutter inside the equipment to remove residual materials and stains

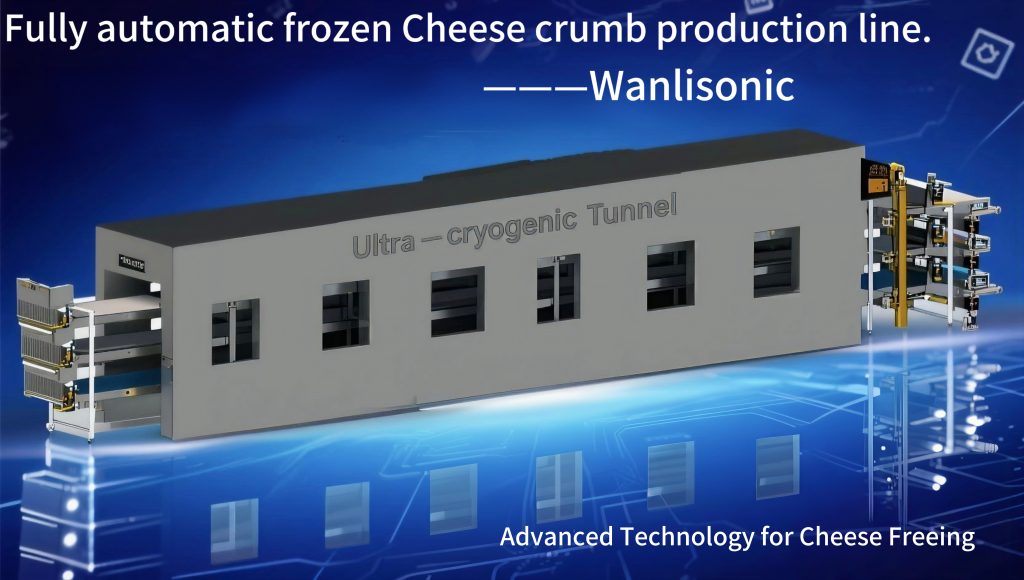

Then the drying system is started to quickly remove the moisture on the surface of the equipment, effectively avoiding bacterial growth, greatly reducing the workload and difficulty of later maintenance and cleaning, and providing a strong guarantee for the long-term stable operation of the equipment.The production line is composed of core parts such as automatic coating system, conveyor belt, teflon pressure roller, freezing tunnel, rolling cutter, high-speed chopper and hoist in sequence according to the production process. All links cooperate closely to realize the fully automated processing of cheese from slurry to final product, and accurately and efficiently send the finished product to the post-packaging line, which greatly improves the production efficiency and product quality stability

1.Cheese industry

2.Baking industry

3.Dessert industry

Features

Main Features:

Model: WANLI2507

Voltage :380V

Rated power :4500W

Frequency: 50Hz-60Hz

Cut type :Cheese production

Material of machine frame: 304 stainless steel

Automatic belt convey :Yes

Convey speed: 0-3000mm{adjustable}

Control System :Four-axis Control System

Cutting speed:300cutes/minute

Wanli Group offers innovative and customized bakery cutting solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your food production.

To reach our anytime via email, please fill out the form below with your request and a company representative will reply to you. To find your local WANLISONIC representative to connect directly click your region in the contact drop down menu.

Contact WANLISONIC For immediate assistance please contact us the corporate headquarters during business hours at 8:00 am – 24:00 pm.

Send Your Inquiry Today