Usage and Cleaning Methods of Ultrasonic Sandwich Cutter

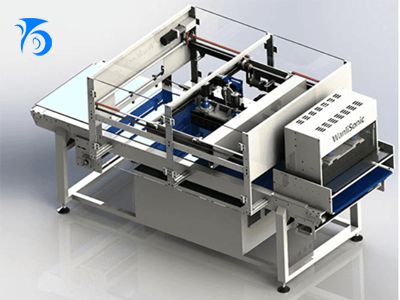

Ultrasonic sandwich cutters are widely used in the food processing industry due to their efficient and precise cutting characteristics. Correctly mastering their usage and cleaning methods can not only ensure the cutting effect, extend the service life of the equipment, but also ensure food hygiene and safety.

Usage

- Equipment Inspection: Before use, carefully check whether all parts of the equipment are in good condition. Check if the connection between the ultrasonic generator and the cutting knife is firm, whether the power cord is damaged, and whether there are foreign objects on the cutting table. Ensure that the equipment is in a normal state to avoid affecting the cutting effect or even causing safety accidents due to loose or damaged parts.

- Parameter Setting: Reasonably set the power and cutting speed of the ultrasonic generator according to the type, thickness, material and other factors of the sandwich. Generally speaking, for sandwiches with soft texture and thin thickness, the power can be appropriately reduced and the cutting speed can be increased; for sandwiches with hard texture and thick thickness, the power needs to be increased and the cutting speed should be slowed down. The specific parameters can refer to the equipment manual and be adjusted through multiple tests to achieve the best cutting effect.

- Placing the Sandwich: Place the sandwich to be cut steadily on the cutting table, ensuring that the position of the sandwich is accurate to avoid deviation during the cutting process. If the sandwich has a multi-layer structure, ensure that each layer is aligned to prevent delamination, breakage, etc. during cutting.

- Starting the Equipment: After confirming that the sandwich is placed correctly, press the start button of the equipment to start the ultrasonic generator. At this time, the cutting knife will vibrate at high frequency under the action of ultrasonic waves, and quickly cut the sandwich. During the cutting process, the operator should closely observe the cutting situation and stop the machine immediately if there is any abnormality.

- Completing the Cutting: When the cutting knife finishes cutting the sandwich, the equipment will stop automatically or the operator will press the stop button. Then, take the cut sandwich from the cutting table for subsequent processing or packaging.

Cleaning Methods

- Preparation Before Cleaning: Before cleaning the equipment, turn off the power of the equipment and unplug the power cord to ensure that the equipment is in a power-off state to avoid electric shock accidents. At the same time, prepare the tools and supplies needed for cleaning, such as clean rags, neutral detergent, clean water, etc.

- Surface Cleaning: Gently wipe the surface of the equipment with a rag dipped in neutral detergent, including the cutting table, machine body, control panel, etc., to remove oil stains, food residues and other dirt on the surface. Be careful not to use strong corrosive detergents or rags with excessive hardness to avoid damaging the coating on the surface of the equipment.

- Cleaning the Cutting Knife: The cutting knife is a key component of the equipment, so it should be cleaned carefully. First, remove the cutting knife from the equipment (refer to the equipment manual for specific disassembly methods), rinse off the food residues on the surface with clean water, then gently brush the blade and gaps of the cutting knife with a soft brush dipped in neutral detergent to remove the remaining dirt. After cleaning, rinse the cutting knife with clean water and dry it with a clean rag.

- Component Installation: Reinstall the cleaned and dried cutting knife to the equipment to ensure it is firmly installed. Then, wipe each part of the equipment again with a clean rag to ensure no detergent residue.

- Post-Cleaning Inspection: After cleaning, check whether all parts of the equipment are installed correctly and whether the surface is clean and tidy. After confirmation, place the equipment in a dry and ventilated environment for next use.

In addition, when using and cleaning the ultrasonic sandwich cutter, operators should wear corresponding protective equipment, such as gloves, to avoid being scratched by the cutting knife during operation. At the same time, regular maintenance of the equipment should be carried out, such as checking the tightness of various parts and adding lubricating oil, to ensure the normal operation of the equipment.