Wanlisonic Ultrasonic Fish Tofu Slicing: The Future of Precision Food Cutting

Have you ever struggled with slicing soft and delicate foods like tofu, cakes, or cheese? Traditional knives often stick, drag, or deform the product, leaving messy cuts. That’s where Wanlisonic ultrasonic fish tofu slicing technology comes in. This cutting-edge method is transforming the food industry by making clean, precise, and efficient cuts possible—even with the trickiest foods.

What is Wanlisonic Ultrasonic Fish Tofu Slicing?

Wanlisonic ultrasonic fish tofu slicing is an advanced food processing solution that uses high-frequency ultrasonic vibrations to cut fish tofu smoothly. Unlike traditional knives, which rely on brute force, ultrasonic blades glide through the food with almost no resistance. This ensures cleaner cuts, higher efficiency, and consistent results.

Why Fish Tofu Requires Special Cutting Technology

Fish tofu is soft, spongy, and elastic. Cutting it with a normal knife often causes squashing, tearing, or sticking. In large-scale production, this leads to uneven portions and wasted product. Ultrasonic cutting eliminates these issues by creating precise, uniform slices without damaging the delicate texture.

How Ultrasonic Cutting Technology Works

The ma]gic lies in ultrasonic vibrations. The machine converts electrical energy into mechanical vibrations at frequencies of 20–40 kHz. These vibrations move the blade microscopically at high speed, reducing friction and preventing sticking. The result? Smooth, effortless cuts with minimal residue.

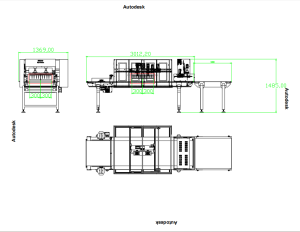

Key Features of Wanlisonic Ultrasonic Fish Tofu Slicing Machine

High-frequency blades that deliver precision cutting.

Food-grade stainless steel design ensuring hygiene and durability.

Safety engineering with automatic shut-off and protective casing.

Automation-ready for integration into production lines.

Advantages Over Traditional Cutting Methods

Clean and smooth slices without crumbling.

No sticking thanks to vibration technology.

Higher speed compared to manual or mechanical knives.

Perfect portioning for consistent product sizes.

Applications Beyond Fish Tofu

While designed for fish tofu, Wanlisonic machines are versatile. They can also handle

Soft cheeses like mozzarella and cheddar.

Cakes, pastries, and Swiss rolls.

Frozen or semi-frozen meat

Confectionery such as nougat or chocolate bars

Technical Specifications of Wanlisonic Machines

Frequencies between 20–40 kHz for optimal slicing

Blade options from straight to serrated, depending on the product.

Energy efficiency with low power consumption.

Customizable systems for conveyor integration.

Hygiene and Food Safety Standards

Wanlisonic machines are designed with easy-to-clean surfaces, quick disassembly, and compliance with HACCP and CE standards. This ensures maximum hygiene and safety for food manufacturers.

Boosting Productivity in Food Manufacturin

By reducing cutting time and minimizing waste, ultrasonic cutting significantly boosts productivity. Factories can produce more with fewer workers and less downtime, making it ideal for both small-scale businesses and large industrial plants.

Cost Efficiency and ROI

Though the initial investment might seem high, ultrasonic slicers quickly pay for themselves. With reduced labor costs, lower product loss, and long-lasting blades, the return on investment (ROI) is impressive.

Case Studies: Wanlisonic in Real Factories

Several fish tofu factories have already adopted Wanlisonic technology. They report:

30% faster production cycles.

Zero product sticking issues.

Better customer satisfaction with uniform products.

Future of Ultrasonic Cutting in the Food Industry

Looking ahead, ultrasonic cutting will integrate with AI-powered robotics, enabling smart portioning, automated quality checks, and even real-time slicing adjustments. The future of food cutting is faster, smarter, and more precise.

Tips for Choosing the Right Ultrasonic Slicer

When investing in a machine, consider:

Your production scale—small vs. large batch.

Budget vs. long-term savings.

After-sales support from the manufacturer.

Customization for different blade shapes and sizes.

Summarizing the role of Wanlisonic in modern food processing:

ultrasonic fish tofu slicing is revolutionizing the way food is processed. From ensuring perfect slices to boosting efficiency, it’s a game-changer for modern food manufacturers. With its precision, hygiene, and versatility, this technology is paving the way for the future of food cutting