Tofu Cutting Machine: 3 Functions + 5 Advantages + 4 Selling Points + 3 Uses Fully Analyzed

Multi-specification Cutting

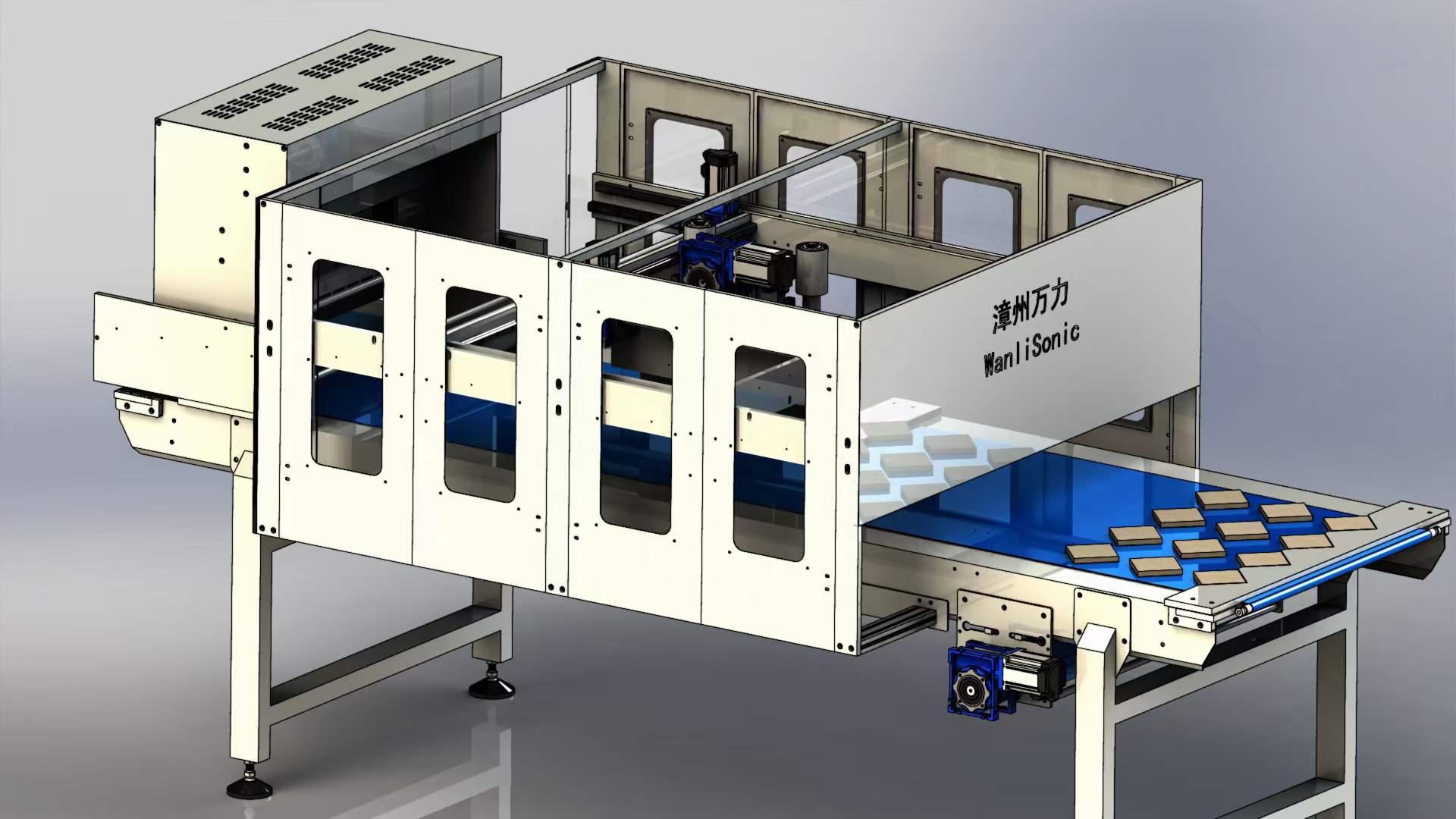

The horizontal tofu cutting machine achieves efficient tofu cutting through precision mechanical structure and intelligent control system, with core functions in the following 3 aspects:

It can accurately complete horizontal slicing (thickness adjustable from 0.5-50mm), vertical dicing (size optional from 1-10cm) and diagonal cutting, suitable for different textures of tofu such as soft tofu, firm tofu and thousand-page tofu. For example, commercial models with dual sets of blades can cut a 10cm thick tofu block into 20 uniform slices at one time.

Standardized Production Control

Driven by a servo motor, the cutting error is controlled within ±0.2mm, ensuring that each piece of tofu is of the same size, solving the problem of uneven thickness in manual cutting, and improving the efficiency of packaging and cooking. For fragile soft tofu, soft conveyor belts and slow-pressure cutting technology can also reduce the breakage rate.

Automated Process Adaptation

It can be connected to the production line to realize the full-process automation of automatic feeding, positioning, cutting and blanking. A single device can process 800-2000 pieces of tofu per hour, meeting the mass production needs of food processing plants and central kitchens.

Compared with traditional manual cutting or single-function equipment, the significant advantages of horizontal tofu cutting machines are reflected in 5 dimensions:

Efficiency Increased by 300%+

Manual cutting can process up to 200 pieces of tofu per hour, while commercial models can reach 800-2000 pieces/hour, greatly shortening the processing time, especially suitable for centralized meal preparation in catering chain enterprises.

Loss Rate Reduced to Below 5%

Using food-grade PU conveyor belt and blunt-edge blade design, it reduces the fragmentation of tofu during transportation and cutting, which is more than 10 percentage points lower than manual cutting (loss rate about 15%).

10 Gears of Precise Thickness Adjustment

The cutting thickness can be set in 0.5mm increments via a knob or touch screen, which can meet the needs of ultra-thin cold salad slices to thick stewed ingredients, adapting to diversified dish requirements.

3 Levels of Safety Protection

Equipped with infrared induction hand guard (the blade stops automatically when the hand is close), emergency stop button and waterproof motor, which meets the safety standards of food processing and reduces operational risks.

Cleaning Time Shortened by 60%

Blades and conveyor belts support quick disassembly. The body is made of 304 stainless steel, which is easy to wipe off oil stains. With high-pressure water gun flushing, the cleaning process is shortened from 30 minutes to less than 12 minutes.

The core competitiveness of the horizontal tofu cutting machine is reflected in 4 major differentiated selling points, directly addressing user pain points:

1 Machine Adapts to 6 Types of Tofu Products

It can stably cut from soft tofu, firm tofu to dried tofu, vegetarian chicken, fried tofu and thousand-page tofu without replacing equipment, reducing enterprise procurement costs.

2 Operation Modes for Free Switching

Supports fully automatic (assembly line linkage) and semi-automatic (manual feeding) modes. Small restaurants can choose semi-automatic models (covering only 0.8㎡), while large factories are suitable for fully automatic assembly line models.

5-Second Quick Knife Change Design

The blade is installed by magnetic attraction and can be replaced without tools, solving the problem of time-consuming knife change (about 20 minutes) of traditional equipment and reducing downtime.

24-Hour Continuous Working Capacity

Equipped with industrial-grade motor and heat dissipation system, it supports all-day uninterrupted operation, meeting the rush work needs of food processing plants, and is more applicable than ordinary models (which need to stop for heat dissipation after 8 hours of continuous work).

Horizontal tofu cutting machines have a wide range of applications, covering 3 core areas:

Catering Industry

Hot pot restaurants and Malatang shops use it to quickly cut tofu into 3cm×3cm standard pieces. Central kitchens of chain fast-food enterprises realize standardized meal preparation through it, ensuring that the specifications of tofu ingredients in each store are consistent.

Food Processing Plants

When producing ready-to-eat tofu products (such as cold mixed tofu and marinated dried tofu), it is used to cut into uniform thickness slices or pieces, which is convenient for subsequent seasoning and packaging; bean product factories use it for preliminary cutting of tofu to prepare for deep processing (such as tofu skin making).

Households and Small Workshops

Small household models (only 5kg in weight) are suitable for cutting homemade tofu, while community tofu workshops can improve the processing efficiency of 50-100 catties of tofu per day through semi-automatic models, reducing manual input.