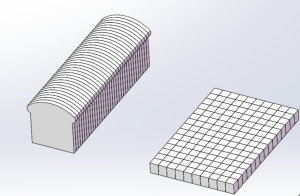

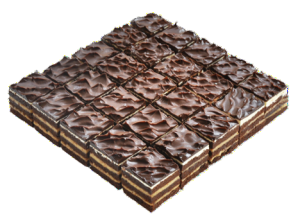

Ultrasonic Brownnie Cake Cutting Machine:The Wanlisp 4-300K900L3500 has two cutting modes, including square section mode and slice mode. Working speed and angle parameters are adjustable.This cutting-edge equipment utilizes ultrasonic technology to achieve precise cuts, ensuring uniformity in every slice. Whether you’re running a bakery or catering to a large event, this machine delivers consistent results with minimal effort.

With the Ultrasonic Brownie Cake Cutting Machine, pastry chefs can say goodbye to the tedious task of manual slicing. This cutting-edge equipment utilizes ultrasonic technology to achieve precise cuts, ensuring uniformity in every slice.

• Hard and soft cheeses, including products containing pieces of nuts and fruit

• Sandwiches, wraps, and pizzas for catering industries

• Nougat, candy bars, granola bars and healthy snack bars

• Semi-frozen meats and breads or cake products

At WANLI, we are proud to radiate our influence to every dessert industry.

Use WANLI. No worries!

Add Your Heading Text Here

单击 “编辑” 按钮更改此文本。这是测试文本。

Impedit egestas aliquet?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Sapien class quo temporibus?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Sapien class quo temporibus?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Elementum voluptate sodales?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Elementum voluptate sodales?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Send Your Inquiry

1. Smooth cut, ultrasonic knife used, no sticky, no crumbs;

2. Various cutting styles, cutting into pieces, diamonds, triangles and circles ;

3. Different products can be cut, cakes, bread, and pizza and so on;

4. With a good interface, easy for operation;

5. Orders available for any different products.

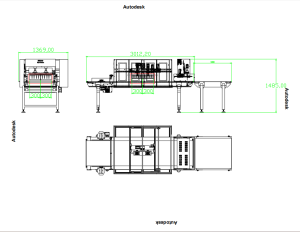

Model:Wanlisp4-300K900L3500

Dimensions:L3000*W1400*H1600mm

Weight:Net Wt. 500KGS, Gross Wt.600KGS

Voltage:220V

Rated power:5000W

Frequency:50Hz-60Hz

Cutting speed:Cross cutting 60 cuts/minute, slitting 30 cuts/minutes

Blade materials:Titanium Alloy

Material of machine frame:Stainless Steel

Wanli Group offers innovative and customized bakery cutting solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your food production.

To reach our anytime via email, please fill out the form below with your request and a company representative will reply to you. To find your local WANLISONIC representative to connect directly click your region in the contact drop down menu.

Contact WANLISONIC For immediate assistance please contact us the corporate headquarters during business hours at 8:00 am – 24:00 pm.

NEWS

Ultrasonic Bread Cutting Machine

Ultrasonic Cake Cutting Machine

Send Your Inquiry Today