Bread is a common food that is widely consumed in our society. However, the production of bread is not an easy task, especially in a competitive market where prices are constantly rising. To address this issue, an automatic bread conveyor has been developed to improve the efficiency and accuracy of bread production. The automatic bread conveyor uses machine learning and artificial intelligence to automate the production process, resulting in higher production rates and better quality bread.

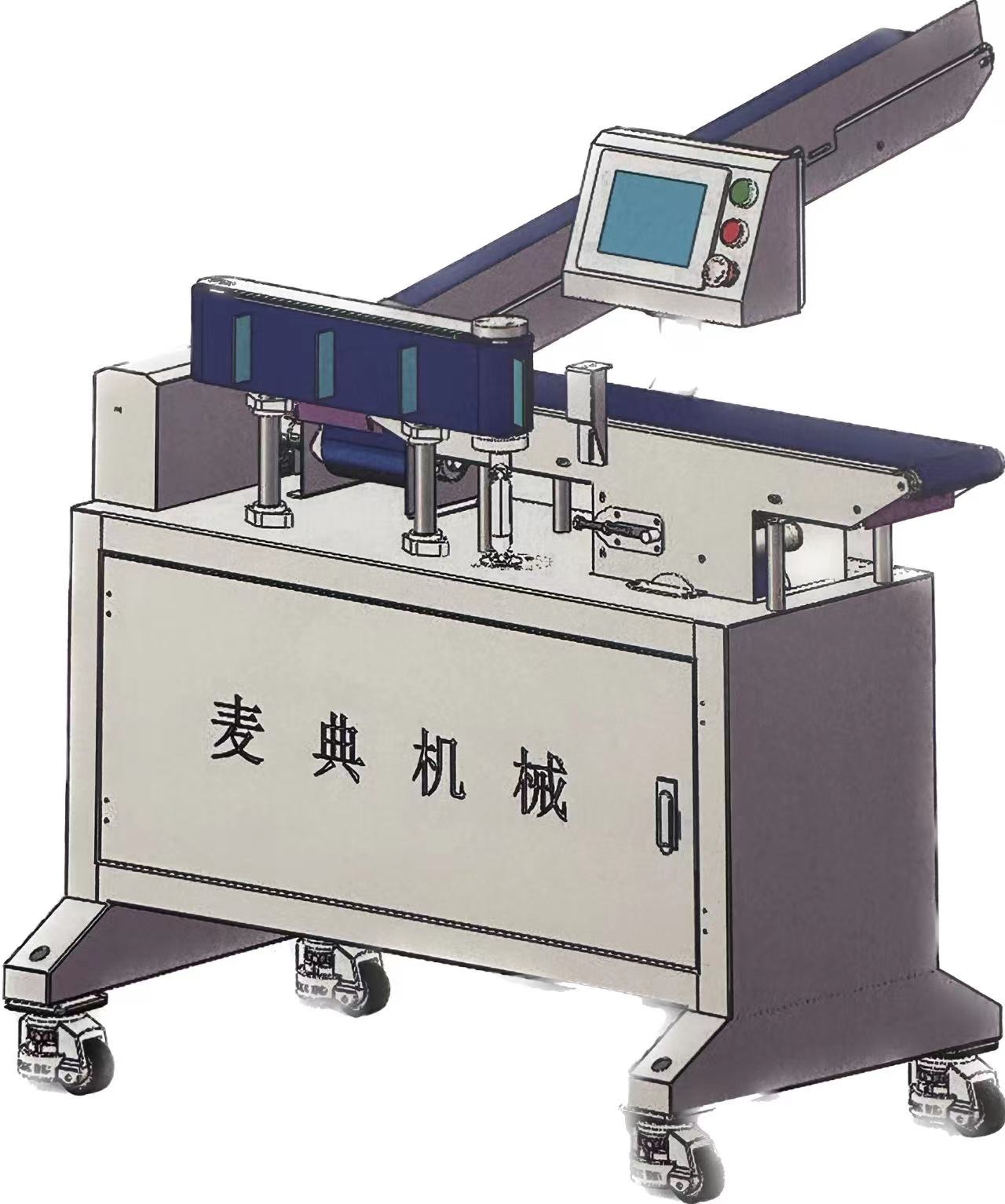

The equipment is mainly used to replace multiple manual workers to smoothly and accurately transport sliced bread, toast, cake, etc. to the sandwich or packaging machine for packaging, saving labor. It is an essential equipment for automation equipment, and our company has patent certification, patent number: ZL2022 2 2 320426.X

The automatic bread conveyor is an advanced equipment widely used in the bread production industry in recent years. It uses advanced technology and an intelligent control system to efficiently handle the bread from dough kneading to baking, packaging, and finally delivering it to the sales area. The following will introduce several main features of the automatic bread conveyor.

First, the automatic bread conveyor has a high degree of flexibility.

Based on different production requirements, it can be set up for multiple bread production processes. By adjusting the speed and direction of the conveyor belt, it can produce bread in different shapes and sizes. This flexibility enables the production line to adapt to market demand changes and provide diverse bread products.

Second, the automatic bread conveyor has excellent production efficiency.

The entire production process does not require manual intervention, greatly improving production efficiency and reducing labor costs.At the same time, thanks to the advanced transmission system, the conveyor belt runs smoothly and ensures that the bread is discharged neatly.

In addition, the automatic bread conveyor belt has an excellent operator interface and intelligent control system.

Production personnel can remotely control the parameters and process settings of the conveyor through touch screen or computer.This intelligent control system allows real-time monitoring and adjustment of parameters during the production process, improving product quality and consistency.

Finally, automatic bread conveyor belts offer reliability and safety.

The equipment utilizes advanced materials and structural design to ensure that the conveyor remains stable and reliable under continuous and intense operation. The belts are also equipped with multiple safety devices, such as emergency stop buttons and sensors, to ensure safety during the production process.

In conclusion, the automatic bread conveyor belt is an excellent equipment for bread production.

Its flexibility, efficiency, intelligence and reliability make the production process more convenient and efficient. Using an automatic bread conveyor for bread production not only improves productivity, but also ensures product quality and consistency.